2024 Insight: How Does A Diesel Generator Work?

A diesel generator set is an internal combustion engine as the driving force of small power generation equipment, in the case of power shortages, diesel generator sets are particularly important, diesel generator sets as a self-contained power station AC emergency power supply equipment have been more and more widely used in major fields.

In the process of procurement of diesel generator sets in various projects, we learned that many owners do not understand why the same brand or even the same power diesel generator set prices will have a large price difference, so we have a brand relationship for diesel generator sets, price composition and other factors affecting the price of the following briefly analyze the factors, followed by a small group of people to understand it today.

The Diesel Generator(DG) Set Introduction

(I) Classification of Diesel Generator Sets

There are many types of diesel generator sets, there are mainly the following eight major classifications:

1. According to the engine fuel classification: can be divided into diesel generator sets and composite fuel generator sets.

2. According to the speed classification: can be divided into high-speed, medium-speed, and low-speed diesel generator sets.

3. According to the use of conditions: can be divided into land-based, marine, trailer-type, and automotive diesel generator sets. Land-based generator sets: including mobile and fixed. Land-based units can be divided into four types: ordinary type, automated type, low noise type, and low noise automated type.

4. According to the generator output voltage and frequency classification: can be divided into AC generator sets and DC generator sets. AC generator sets: medium frequency 40Hz and industrial frequency 50Hz, 50Hz industrial frequency of small and medium-sized generator sets of the calibration voltage is generally 400V, the calibration voltage of large generators is generally 630-1050V.

5. According to the synchronous generator excitation mode classification: can be divided into rotating AC exciter and static exciter.

6. Classified according to the use: common unit, standby unit, emergency unit.

7. Classified according to the way of control and operation: it can be divided into field operation generator sets, compartment operation generator sets, and automation generator sets.

8 according to automation function classification: can be divided into basic diesel generator sets, automatic start diesel generator sets, and microcomputer automatic control of diesel generator sets.

(ii) The Use of Diesel Generator Sets

A diesel generator is a small power generation equipment, that refers to the diesel fuel, diesel engine as the prime mover to drive the generator power machinery.

Although the power of the diesel generator set is low because of its small size, flexible, lightweight, complete support easy to operate and maintain so it is widely used in mining, railways, field construction sites, road traffic maintenance, as well as factories, enterprises, hospitals, and other departments as a back-up power supply or temporary power supply.

In the purchase, pay attention to the performance and quality of the selected diesel generator set must meet the relevant standard requirements, but also according to the purpose of the unit, the use of environmental conditions, and other factors to choose from. As diesel generator sets can be used for common use, standby, and emergency situations, the requirements for different uses of diesel generator sets are different.

Are you looking for a reliable and efficient power source for your industry? Kotech dealers are experienced in finding the perfect air compressor for your needs.

Contact your local Kotech dealer today and discover how an air compressor can increase your productivity and safety.

(iii) Composition of Diesel Generator Sets

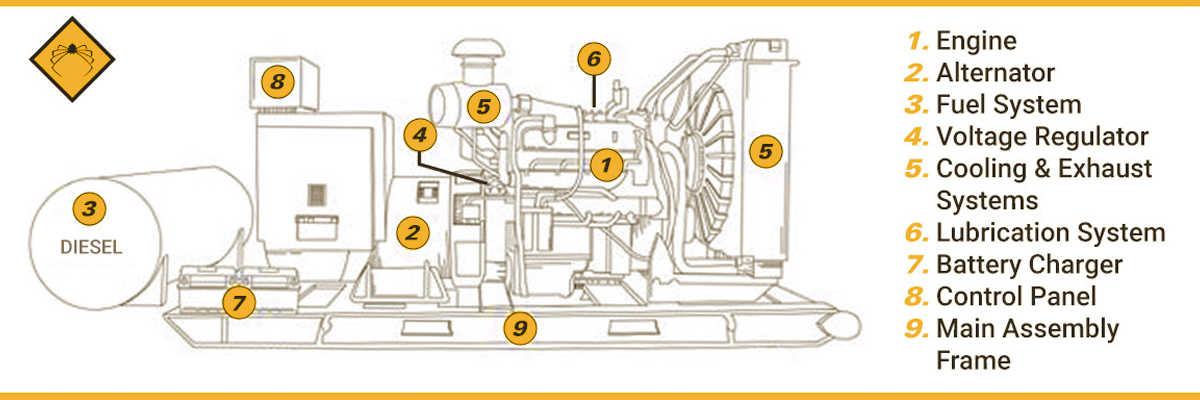

Diesel generator set by the base, diesel engine, base tank, generator set (i.e., electric ball), controller (plays a role in controlling, but also plays a role in protecting the unit), radiator (air-cooled: fan; water-cooled: water tank), static speaker and other components.

(iv) The Principle of Diesel Generator Sets

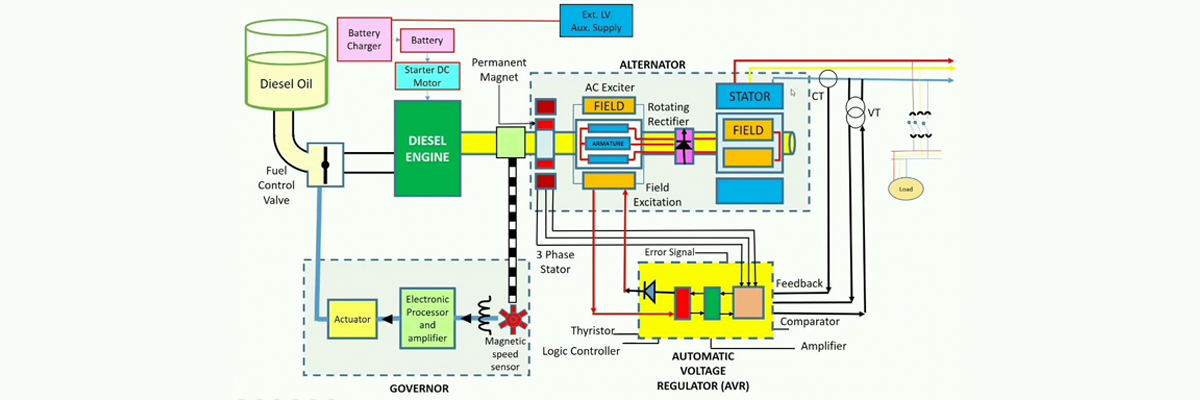

The diesel engine drives the generator to run, converting the energy of diesel into electricity. In the diesel engine cylinder, after the air filter filters clean air and injector nozzles inject high-pressure atomized diesel fuel fully mixed, in the piston upward pressure, volume reduction, the temperature rises rapidly, reaching the ignition point of diesel fuel.

Diesel fuel is ignited, the gas mixture burns violently, and the volume expands rapidly, pushing the piston down, known as ‘work’. The cylinders in a certain order to work, acting on the piston thrust through the connecting rod into the crankshaft to promote the power of rotation, thus driving the crankshaft rotation.

Brushless synchronous alternator and diesel engine crankshaft coaxial installation, you can use the rotation of the diesel engine to drive the rotor generator, the use of the ‘electromagnetic induction’ principle, the generator will output induced electromotive force, through the closed load circuit can produce current.

To get available, stable power output, but also needs a series of diesel engine and generator control, protection devices, and circuits.

(v) The Performance Level of Diesel Generator Sets

National(China) standard GB/T2820. 1-1997 ‘reciprocating internal combustion engine-driven alternating current generator sets’ Part I: use, quota, and performance of Article 7 of the diesel generator set provides four levels of performance.

1. G1 level performance requirements apply to connected loads for which only the basic parameters of voltage and frequency need to be specified. General purposes such as lighting and other simple electrical loads.

2. G2 level requirements apply to loads that have the same requirements for voltage characteristics as the utility power system. There can be temporary however permissible deviations in voltage and frequency when their load varies. Such as lighting systems, pumps, and fans.

3. G3 level requirements apply to the frequency, voltage, and waveform characteristics of the strict requirements of the connected equipment. Such as radio communications and thyristor rectifier-controlled loads.

4. G4 level requirements apply to the frequency, voltage, and waveform characteristics of the load have particularly strict requirements. Such as data processing equipment or computer systems.

(vi) How to Identify the Model of Diesel Generator Sets?

To facilitate production management and use, the national standards for diesel generators set model preparation methods to make uniform provisions. The set of models arranged and the meaning of the symbols are as follows:

1. The rated power output of the unit (KW) is expressed in figures.

2. The type of output current of the unit: G – AC frequency; P – AC medium frequency; S – AC double frequency; Z – current.

3. The type of unit: F-land; FC a marine; Q-automotive power station; T a trailer (trailer).

4. Control characteristics of the unit: absence of manual (ordinary); Z-automation; S-low noise; SZ-low noise automation.

5. Design serial number, expressed in figures.

6. Variant code, expressed in numbers.

7. Environmental characteristics: absence of ordinary type; TH – humid and hot zone type.

Note: Some diesel generator set series models and the above model meaning is different, especially imported or joint venture production of diesel generator sets is determined by the unit manufacturer itself.

The Diesel Generator Set Installation Specification

(i) Ventilation

1. Air inlet: according to the capacity of the diesel generator set, the manufacturer gives the size of the air inlet requirements, Party A in the construction should be reserved for the air inlet.

2. Exhaust port: according to the diesel generator set capacity, can determine the size of the exhaust port, Party A in the construction of the exhaust port reserved.

(ii) Smoke exhaust

Smoke must be discharged directly to the outdoors by a properly designed discharge system, which should be fitted with a random smoke silencer, and the outer end of the pipe should be cut at an angle of 60 degrees to the horizontal, or fitted with an exhaust hood system to protect against rain or snow.

(iii) Foundation and fixing

According to the capacity of the diesel generator set, the unit gives the corresponding foundation size to meet the normal operation of the unit load requirements, the foundation requirements for the concrete floor.

The alternator and engine are accurately mounted on a steel frame from the factory, therefore, the unit only needs to be fixed on a good foundation with high-quality expansion bolts when it is installed.

Global Top 6 Diesel Generator Manufacturers

| Brand | Founded | Generator Portfolio Includes |

|---|---|---|

| Aggreko | 1962 | 30 – 600 kVA Stage V Generator 125 – 500 kVA Diesel Generator 500 – 2100 kVA Containerized Diesel Generator |

| Atlas Copco | 1873 |

|

| Caterpillar Inc. | 1925 |

With power potential from 6-5,720 eKW (7.5-7,150 kVA)

|

| Cummins Inc. | 1919 |

|

| Generac Holdings, Inc. | 1959 |

|

| Yanmar Co., Ltd. | 1912 |

|