KVW Series

Gas Booster Air Compressor

The Gas Booster Air Compressor is a type of air compressor that is designed to provide a more efficient and cost-effective source of compressed air than traditional compressors. This type of compressor uses a combination of a compressor and a gas turbine to increase the pressure of the air, resulting in a compressor that is quieter and more efficient.

Social Sharing:

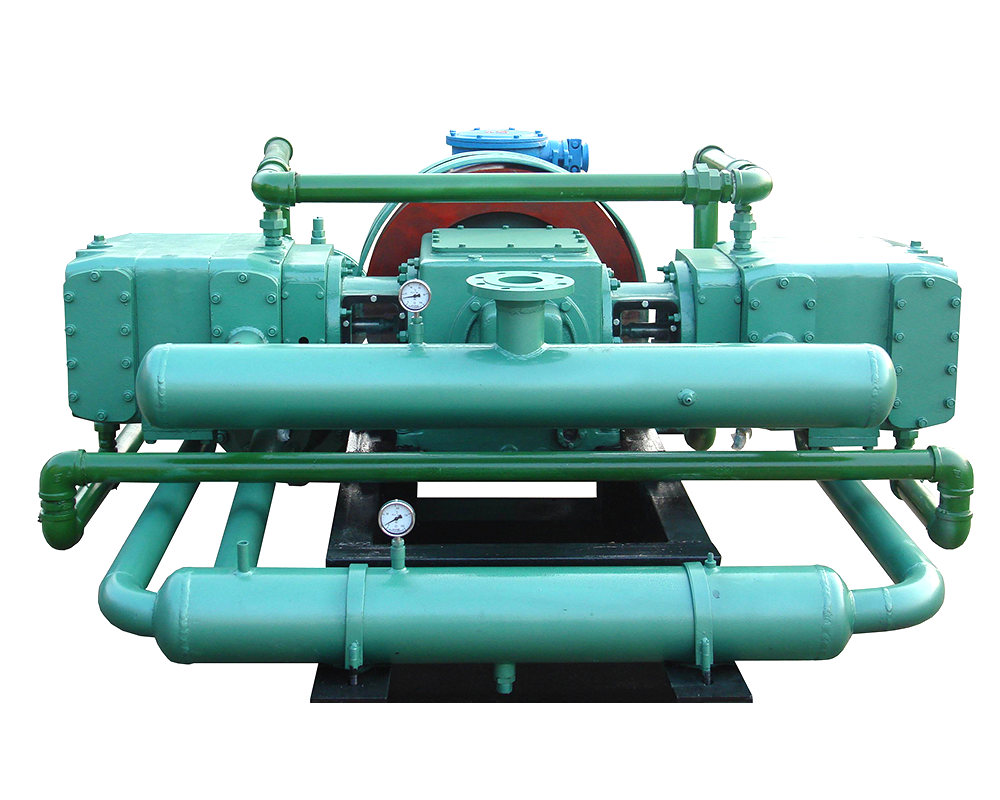

Technical Characteristic:

The gas compressor series are water cooling, oil free recprocating compressor. The pressure lubricating system is used for crankcase connecting rod, crosshead and the oil free system is used for cylinder and padding.

The compressor is composed of compressor, motor, shaft coupling, flywheel, pipeline, cooling system, electrical equipment and auxiliary equipment, and etc. The compressors of this series are made with the advanced Germany technology, with good quality and long service life.

The gas compressors are totally oil free, with low noise, small vibration, compact in design, smooth in running, safety and reliable in operation, and high in automatic control level. Meanwhile, in keeping with the client’s requirements, the digital remote display and control can be provided with the compressor to have some alarm functions if too low oil pressure, too low water pressure, too high temperature, too low intake pressure and too high discharge pressure in order to ensure the compressor at safer and more reliable running.

The compressors are widely used in the flow processes of constant voltage modulation, pressure charging and purging, and also as the stabl power plant,food industry,medicine-making industry and test and research institutes.

Meeting all your compressed gas needs:

Kotech is one of the world’s leading companies in air and gas compression, global leader in air compressors and its spare parts manufacturer with total integrated digital technology. Our complete range of compressed gas solutions is characterized by outstanding product and component quality.

We can handle a wide variety of gases and gas mixtures and can tailor our gas compressors to the specific requirements of your processes:

- ·Compressed Natural Gas ( CNG)

- ·Chlorine

- ·Natural Gas

- ·Vinyl Chloride

- ·Hydrogen

- ·Oxygen

- ·Rich Gas

- ·Casing Gas

- ·Liquefied Gas

- ·Biogas

| Model | Compression Media | Air delivery | Input Pressure | Output Pressure | Power | Dimension(L*W*H) | Weight |

| m³/min | Mpa | Mpa | Kw | mm | Kg | ||

| KVW-6/16-24 | Oxygen | 6 | 1.6 | 2.4 | 110 | 2140x1750x1730 | 2600 |

| KVW-6/(0-1.62)-(5-21.2) | Natural Gas | 6 | 0-0.162 | 0.5-2.12 | 75 | 3530x2140x1900 | 2350 |

| KVW-6.7/5-10 | Natural Gas | 6.7 | 0.5 | 1 | 90 | 2260x1700x1800 | 2500 |

| KVW-26.7/0.5-10 | Natural Gas | 26.7 | 0.05 | 1 | 250 | 4000x2000x2000 | 4500 |

| KVW-31/2.2-3.5 | Natural Gas | 31 | 0.22 | 0.35 | 90 | 2500x1800x1550 | 2700 |

| KDW-2/0.2-16 | Freon | 2 | 0.02 | 1.6 | 22 | 1890x1690x980 | 1500 |

| KVW-3/30 | Nitron | 3 | Atmospheric pressure | 3 | 30 | 2000x14800x1550 | 2100 |

| KZW-0.45/0.8-7.5 | Nitron | 0.45 | 0.08 | 0.75 | 5.5 | 1280x590x900 | 750 |

| KVW-3/8 | Propylene | 3 | Atmospheric pressure | 0.8 | 22 | 1585x1630x1600 | 1500 |

| KVW-6.7/22 | Propylene | 6.7 | Atmospheric pressure | 2.2 | 55 | 2300x1700x1850 | 2500 |

| K2VW-50/3.5 | Carbon Dioxide | 50 | Atmospheric pressure | 0.35 | 220 | 3350x1850x1650 | 2500 |

| KZW-1/10 | Dimethyl ether | 1 | Atmospheric pressure | 1 | 7.5 | 1400x1200x940 | 1450 |

| KVW-2.5/6 | Butene Gas | 2.5 | Atmospheric pressure | 0.6 | 18.5 | 1950x1850x1600 | 1850 |

| KVW-7/16 | Difluoromethane | 7.0 | Atmospheric pressure | 1.6 | 75 | 2300x1950x1750 | 3000 |

| KVW-20/8 | Difluorothane | 20 | Atmospheric pressure | 0.8 | 132 | 2150x1800x1650 | 3200 |

| KVW-6/0.6-2 | Alcohol Steame | 6 | 0.06 | 0.2 | 22 | 1900x1550x1500 | 2000 |

| KVW-12.5/7 | Fluoroethylene | 12.5 | Atmospheric pressure | 0.7 | 75 | 2100x1750x1400 | 2500 |

| KDW-2/15 | Pentafluoroethane | 2.0 | Atmospheric pressure | 1.5 | 22 | 1650x2000x1300 | 1850 |

| KVW-4.5/16 | Pentafluoroethane | 4.5 | Atmospheric pressure | 1.6 | 37 | 2300x1750x1650 | 2500 |

| K2VW-25/0.5-16 | The Casting Head Gas | 25 | 0.05 | 1.6 | 220 | 3350x1800x1550 | 6000 |

| KVW-6/0.02-4 | The Casting Head Gas | 6 | 0.002 | 0.4 | 30 | 2000x1670x1600 | 2000 |

| KVW-8.5/0.2-12 | Liquefied Gas | 8.5 | 0.02 | 1.2 | 75 | 1930x1630x1050 | 2100 |

| KVW-7.2/1.2-23S | Natural Gas | 7.2 | 0.12 | 2.3 | 132 | 2350x1570x1475 | 2750 |

| KVW-5/0.5-3 | Natural Gas | 5 | 0.052 | 0.3 | 22 | 1650x1750x1650 | 2100 |

| KVW-4.5/0.5-10 | Propylene | 4.5 | 0.05 | 1 | 37 | 1750x1500x1550 | 2100 |

| KVW-5/0.2-11 | Propylene | 5 | 0.02 | 1.1 | 37 | 1850x1500x1550 | 1950 |

| KVW-14/1.5-16 | Chloromethane | 14 | 0.15 | 1.6 | 110 | 2050x1750x1550 | 3700 |

| KVW-4.7/2.5-6.9 | Natural Gas | 4.7 | 0.25 | 0.69 | 37 | 1750x1550x1600 | 2000 |

| KVW-3.5/0.5-7 | Isobutylene | 3.5 | 0.05 | 0.7 | 37 | 1800x1630x1550 | 2100 |

| KVW-1.4/4-50 | Natural Gas | 1.4 | 0.4 | 5 | 45 | 2200x1650x1600 | 2500 |

| KVW-7.2/1-7 | Natural Gas | 7.2 | 0.1 | 0.7 | 55 | 2100x1800x1450 | 2500 |

| KVWWJ-3.1/1.25-23.5 | Natural Gas | 3.1/td> | 0.125 | 2.35 | 55 | 1940x1650x1650 | 2500 |

| KVW-3/2-45 | Nitrogen | 3 | 0.2 | 4.5 | 75 | 1900x1550x1600 | 2600 |

| KVW-13/0.02-3 | Gas | 13 | 0.002 | 0.3 | 75 | 2000x1630x1450 | 2500 |

| KVW-6.5/(1-3)-7 | Natural Gas | 6.5 | 0.1-0.3 | 0.7 | 37 | 1900x1500x1550 | 1900 |

| Model | Compression Media | Air delivery | Input Pressure | Output Pressure | Power | Dimension(L*W*H) | Weight |

| m³/min | Mpa | Mpa | Kw | mm | Kg | ||

| KVW-11.7/0.4-7 | Chlorine | 11.7 | 0.04 | 0.7 | 45 | 2300x750x1450 | 2000 |

| KVW-5.6/(1.5-2)-25 | Natural Gas | 5.6 | 0.15-0.2 | 2.5 | 55 | 1850x1500x1550 | 2000 |

| KVWWJ-12.3/0.3-10 | Vinyl Chloride | 12.3 | 0.03 | 1 | 75 | 2100x1750x1550 | 3000 |

| KVWWJ-7/2.5-1.4 | Vinyl Chloride | 7 | 0.25 | 1.4 | 75 | 2850x1570x1475 | 3150 |

| KVWWJ-7.5/0.G-19 | Natural Gas | 7.5 | 0.06 | 1.9 | 90 | 2350X1570X1475 | 2450 |

| KVW-3.5/0.5-5 | Oilfield Gas | 3.5 | 0.05 | 0.5 | 22 | 2000x1550x1550 | 2100 |

| KVW-28/(0.1-1.5)-3.5 | Oilfield Gas | 28 | 0.01-0.15 | 0.35 | 110 | 2300x1650x1550 | 3300 |

| KVW-2.5/3-250 | Oilfield Gas | 2.5 | 0.3 | 25 | 110 | 2400x1600x1850 | 3500 |

| KVW-31/2.2-3.5 | Gas | 31 | 0.22 | 0.35 | 90 | 2500x1800x1550 | 2700 |

| KVW-31/2.2-3.5 | Air | 25 | Atmospheric Pressure | 2.5 | 250 | 2800x1850x1550 | 2100 |

| KZW-2.3/24-33 | Hydrogen | 2.3 | 2.4 | 3.3 | 55 | 1200x950x1300 | 1700 |

| KZW-9/5-8 | Chlorine | 9 | 0.5 | 0.8 | 75 | 2200x1400x1600 | 2800 |

| KZW-3/0.5-4 | Oxygen | 3 | 0.05 | 0.4 | 22 | 1400x850x1260 | 1400 |

| K2VW-16.7/0.5-20 | Rich Gas | 16.7 | 0.05 | 2 | 185 | 4200x1600x1600 | 6500 |

| KZW-0.67/4-(8-10) | Casing Gas | 0.67 | 0.4 | 0.8-1.0 | 7.5 | 1305x700x900 | 370 |

| KZW-0.6/6-10 | Liquefied gas | 0.6 | 0.6 | 1 | 5.5 | 1305x700x900 | 760 |

| KZW-3/1-2 | Gas | 3 | 0.1 | 0.2 | 11 | 1400x900x1300 | 900 |

| KZW-0.33/10 | Biogas | 0.33 | Atmospheric Pressure | 1 | 3 | 1305x700x900 | 390 |

| KZW-0.46/(5-10)-(15-20) | Casing Gas | 0.46 | 0.5-1.0 | 1.5-2.0 | 11 | 1500x900x1100 | 850 |

| KZW-0.93/(5-10)-(15-20) | Casing Gas | 0.93 | 0.5-1.0 | 1.5-2.0 | 22J | 1500x900x1100 | 970 |

| KZW-0.5/1-25 | Nitrogen | 0.5 | 1 | 2.5 | 15 | 1400x1300x1300 | 950 |

| KZW-0.75/2.5-5 | Nitrogen | 0.75 | 0.25 | 0.5 | 5.5 | 1305x200x900 | 520 |

| KZW-0.8/12 | Propylene | 0.8 | Atmospheric Pressure | 1.2 | 7.5 | 1800x1200x1000 | 1200 |

| KZW-0.9/3-18 | Propylene | 0.9 | 0.3 | 1.8 | 18.5 | 1420x970x1250 | 2500 |

| KDW-4.5/0.5-13 | Propylene | 4.5 | 0.05 | 1.3 | 45 | 2000x2030x1060 | 2500 |

| KDW-9.5/7 | Butadiene | 9.5 | Atmospheric Pressure | 0.7 | 55 | 2000x2030x1060 | 2600 |

| KDW-5.5/1.2-24 | Butadiene | 5.5 | 0.12 | 2.4 | 90 | 3000x2030x1060 | 3500 |

| KVW-8/20 | Freon | 8 | Atmospheric Pressure | 2 | 75 | 2200x1900x2100 | 3500 |

| KVW-5/21 | Low Temperature Ethylene | 5 | Atmospheric Pressure | 2.1 | 55 | 2100x1800x1600 | 3000 |

| KVW-80/2 | Coalbed Methane | 80 | Atmospheric Pressure | 0.2 | 250 | 4400x2100x2200 | 7500 |

| KZW-0.67/17-21 | Oxygen | 0.67 | 1.7 | 2.1 | 11 | 1400x500x1450 | 1000 |

| KZW-33/0.1-17 | Oxygen | 33 | 0.01 | 1.7 | 250 | 4500x2000x2200 | 1000 |

| KVW-10/0.5-8 | Isobutylene | 10 | 0.05 | 0.8 | 45 | 2200x1600x1500 | 1000 |

| KVW-5/8 | Propane | 5 | Atmospheric Pressure | 0.8 | 37 | 2100x1600x1500 | 2000 |

| KVW-6.4/0.5-8 | Methyl Chloride | 6.4 | 0.05 | 0.8 | 55 | 2200x1500x1500 | 2500 |

| *Tips: 1.Other air delivery and pressure can be customized as per requirement. 2.The above parameters are subject to change, please ask your sales engineer. |

|||||||

Technical Characteristic:

The gas compressor series are water cooling, oil free recprocating compressor. The pressure lubricating system is used for crankcase connecting rod, crosshead and the oil free system is used for cylinder and padding.

The compressor is composed of compressor, motor, shaft coupling, flywheel, pipeline, cooling system, electrical equipment and auxiliary equipment, and etc. The compressors of this series are made with the advanced Germany technology, with good quality and long service life.

The gas compressors are totally oil free, with low noise, small vibration, compact in design, smooth in running, safety and reliable in operation, and high in automatic control level. Meanwhile, in keeping with the client’s requirements, the digital remote display and control can be provided with the compressor to have some alarm functions if too low oil pressure, too low water pressure, too high temperature, too low intake pressure and too high discharge pressure in order to ensure the compressor at safer and more reliable running.

The compressors are widely used in the flow processes of constant voltage modulation, pressure charging and purging, and also as the stabl power plant,food industry,medicine-making industry and test and research institutes.

Meeting all your compressed gas needs:

Kotech is one of the world’s leading companies in air and gas compression, global leader in air compressors and its spare parts manufacturer with total integrated digital technology. Our complete range of compressed gas solutions is characterized by outstanding product and component quality.

We can handle a wide variety of gases and gas mixtures and can tailor our gas compressors to the specific requirements of your processes:

- ·Compressed Natural Gas ( CNG)

- ·Chlorine

- ·Natural Gas

- ·Vinyl Chloride

- ·Hydrogen

- ·Oxygen

- ·Rich Gas

- ·Casing Gas

- ·Liquefied Gas

- ·Biogas

| Model | Compression Media | Air delivery | Input Pressure | Output Pressure | Power | Dimension(L*W*H) | Weight |

| m³/min | Mpa | Mpa | Kw | mm | Kg | ||

| KVW-6/16-24 | Oxygen | 6 | 1.6 | 2.4 | 110 | 2140x1750x1730 | 2600 |

| KVW-6/(0-1.62)-(5-21.2) | Natural Gas | 6 | 0-0.162 | 0.5-2.12 | 75 | 3530x2140x1900 | 2350 |

| KVW-6.7/5-10 | Natural Gas | 6.7 | 0.5 | 1 | 90 | 2260x1700x1800 | 2500 |

| KVW-26.7/0.5-10 | Natural Gas | 26.7 | 0.05 | 1 | 250 | 4000x2000x2000 | 4500 |

| KVW-31/2.2-3.5 | Natural Gas | 31 | 0.22 | 0.35 | 90 | 2500x1800x1550 | 2700 |

| KDW-2/0.2-16 | Freon | 2 | 0.02 | 1.6 | 22 | 1890x1690x980 | 1500 |

| KVW-3/30 | Nitron | 3 | Atmospheric pressure | 3 | 30 | 2000x14800x1550 | 2100 |

| KZW-0.45/0.8-7.5 | Nitron | 0.45 | 0.08 | 0.75 | 5.5 | 1280x590x900 | 750 |

| KVW-3/8 | Propylene | 3 | Atmospheric pressure | 0.8 | 22 | 1585x1630x1600 | 1500 |

| KVW-6.7/22 | Propylene | 6.7 | Atmospheric pressure | 2.2 | 55 | 2300x1700x1850 | 2500 |

| K2VW-50/3.5 | Carbon Dioxide | 50 | Atmospheric pressure | 0.35 | 220 | 3350x1850x1650 | 2500 |

| KZW-1/10 | Dimethyl ether | 1 | Atmospheric pressure | 1 | 7.5 | 1400x1200x940 | 1450 |

| KVW-2.5/6 | Butene Gas | 2.5 | Atmospheric pressure | 0.6 | 18.5 | 1950x1850x1600 | 1850 |

| KVW-7/16 | Difluoromethane | 7.0 | Atmospheric pressure | 1.6 | 75 | 2300x1950x1750 | 3000 |

| KVW-20/8 | Difluorothane | 20 | Atmospheric pressure | 0.8 | 132 | 2150x1800x1650 | 3200 |

| KVW-6/0.6-2 | Alcohol Steame | 6 | 0.06 | 0.2 | 22 | 1900x1550x1500 | 2000 |

| KVW-12.5/7 | Fluoroethylene | 12.5 | Atmospheric pressure | 0.7 | 75 | 2100x1750x1400 | 2500 |

| KDW-2/15 | Pentafluoroethane | 2.0 | Atmospheric pressure | 1.5 | 22 | 1650x2000x1300 | 1850 |

| KVW-4.5/16 | Pentafluoroethane | 4.5 | Atmospheric pressure | 1.6 | 37 | 2300x1750x1650 | 2500 |

| K2VW-25/0.5-16 | The Casting Head Gas | 25 | 0.05 | 1.6 | 220 | 3350x1800x1550 | 6000 |

| KVW-6/0.02-4 | The Casting Head Gas | 6 | 0.002 | 0.4 | 30 | 2000x1670x1600 | 2000 |

| KVW-8.5/0.2-12 | Liquefied Gas | 8.5 | 0.02 | 1.2 | 75 | 1930x1630x1050 | 2100 |

| KVW-7.2/1.2-23S | Natural Gas | 7.2 | 0.12 | 2.3 | 132 | 2350x1570x1475 | 2750 |

| KVW-5/0.5-3 | Natural Gas | 5 | 0.052 | 0.3 | 22 | 1650x1750x1650 | 2100 |

| KVW-4.5/0.5-10 | Propylene | 4.5 | 0.05 | 1 | 37 | 1750x1500x1550 | 2100 |

| KVW-5/0.2-11 | Propylene | 5 | 0.02 | 1.1 | 37 | 1850x1500x1550 | 1950 |

| KVW-14/1.5-16 | Chloromethane | 14 | 0.15 | 1.6 | 110 | 2050x1750x1550 | 3700 |

| KVW-4.7/2.5-6.9 | Natural Gas | 4.7 | 0.25 | 0.69 | 37 | 1750x1550x1600 | 2000 |

| KVW-3.5/0.5-7 | Isobutylene | 3.5 | 0.05 | 0.7 | 37 | 1800x1630x1550 | 2100 |

| KVW-1.4/4-50 | Natural Gas | 1.4 | 0.4 | 5 | 45 | 2200x1650x1600 | 2500 |

| KVW-7.2/1-7 | Natural Gas | 7.2 | 0.1 | 0.7 | 55 | 2100x1800x1450 | 2500 |

| KVWWJ-3.1/1.25-23.5 | Natural Gas | 3.1/td> | 0.125 | 2.35 | 55 | 1940x1650x1650 | 2500 |

| KVW-3/2-45 | Nitrogen | 3 | 0.2 | 4.5 | 75 | 1900x1550x1600 | 2600 |

| KVW-13/0.02-3 | Gas | 13 | 0.002 | 0.3 | 75 | 2000x1630x1450 | 2500 |

| KVW-6.5/(1-3)-7 | Natural Gas | 6.5 | 0.1-0.3 | 0.7 | 37 | 1900x1500x1550 | 1900 |

| Model | Compression Media | Air delivery | Input Pressure | Output Pressure | Power | Dimension(L*W*H) | Weight |

| m³/min | Mpa | Mpa | Kw | mm | Kg | ||

| KVW-11.7/0.4-7 | Chlorine | 11.7 | 0.04 | 0.7 | 45 | 2300x750x1450 | 2000 |

| KVW-5.6/(1.5-2)-25 | Natural Gas | 5.6 | 0.15-0.2 | 2.5 | 55 | 1850x1500x1550 | 2000 |

| KVWWJ-12.3/0.3-10 | Vinyl Chloride | 12.3 | 0.03 | 1 | 75 | 2100x1750x1550 | 3000 |

| KVWWJ-7/2.5-1.4 | Vinyl Chloride | 7 | 0.25 | 1.4 | 75 | 2850x1570x1475 | 3150 |

| KVWWJ-7.5/0.G-19 | Natural Gas | 7.5 | 0.06 | 1.9 | 90 | 2350X1570X1475 | 2450 |

| KVW-3.5/0.5-5 | Oilfield Gas | 3.5 | 0.05 | 0.5 | 22 | 2000x1550x1550 | 2100 |

| KVW-28/(0.1-1.5)-3.5 | Oilfield Gas | 28 | 0.01-0.15 | 0.35 | 110 | 2300x1650x1550 | 3300 |

| KVW-2.5/3-250 | Oilfield Gas | 2.5 | 0.3 | 25 | 110 | 2400x1600x1850 | 3500 |

| KVW-31/2.2-3.5 | Gas | 31 | 0.22 | 0.35 | 90 | 2500x1800x1550 | 2700 |

| KVW-31/2.2-3.5 | Air | 25 | Atmospheric Pressure | 2.5 | 250 | 2800x1850x1550 | 2100 |

| KZW-2.3/24-33 | Hydrogen | 2.3 | 2.4 | 3.3 | 55 | 1200x950x1300 | 1700 |

| KZW-9/5-8 | Chlorine | 9 | 0.5 | 0.8 | 75 | 2200x1400x1600 | 2800 |

| KZW-3/0.5-4 | Oxygen | 3 | 0.05 | 0.4 | 22 | 1400x850x1260 | 1400 |

| K2VW-16.7/0.5-20 | Rich Gas | 16.7 | 0.05 | 2 | 185 | 4200x1600x1600 | 6500 |

| KZW-0.67/4-(8-10) | Casing Gas | 0.67 | 0.4 | 0.8-1.0 | 7.5 | 1305x700x900 | 370 |

| KZW-0.6/6-10 | Liquefied gas | 0.6 | 0.6 | 1 | 5.5 | 1305x700x900 | 760 |

| KZW-3/1-2 | Gas | 3 | 0.1 | 0.2 | 11 | 1400x900x1300 | 900 |

| KZW-0.33/10 | Biogas | 0.33 | Atmospheric Pressure | 1 | 3 | 1305x700x900 | 390 |

| KZW-0.46/(5-10)-(15-20) | Casing Gas | 0.46 | 0.5-1.0 | 1.5-2.0 | 11 | 1500x900x1100 | 850 |

| KZW-0.93/(5-10)-(15-20) | Casing Gas | 0.93 | 0.5-1.0 | 1.5-2.0 | 22J | 1500x900x1100 | 970 |

| KZW-0.5/1-25 | Nitrogen | 0.5 | 1 | 2.5 | 15 | 1400x1300x1300 | 950 |

| KZW-0.75/2.5-5 | Nitrogen | 0.75 | 0.25 | 0.5 | 5.5 | 1305x200x900 | 520 |

| KZW-0.8/12 | Propylene | 0.8 | Atmospheric Pressure | 1.2 | 7.5 | 1800x1200x1000 | 1200 |

| KZW-0.9/3-18 | Propylene | 0.9 | 0.3 | 1.8 | 18.5 | 1420x970x1250 | 2500 |

| KDW-4.5/0.5-13 | Propylene | 4.5 | 0.05 | 1.3 | 45 | 2000x2030x1060 | 2500 |

| KDW-9.5/7 | Butadiene | 9.5 | Atmospheric Pressure | 0.7 | 55 | 2000x2030x1060 | 2600 |

| KDW-5.5/1.2-24 | Butadiene | 5.5 | 0.12 | 2.4 | 90 | 3000x2030x1060 | 3500 |

| KVW-8/20 | Freon | 8 | Atmospheric Pressure | 2 | 75 | 2200x1900x2100 | 3500 |

| KVW-5/21 | Low Temperature Ethylene | 5 | Atmospheric Pressure | 2.1 | 55 | 2100x1800x1600 | 3000 |

| KVW-80/2 | Coalbed Methane | 80 | Atmospheric Pressure | 0.2 | 250 | 4400x2100x2200 | 7500 |

| KZW-0.67/17-21 | Oxygen | 0.67 | 1.7 | 2.1 | 11 | 1400x500x1450 | 1000 |

| KZW-33/0.1-17 | Oxygen | 33 | 0.01 | 1.7 | 250 | 4500x2000x2200 | 1000 |

| KVW-10/0.5-8 | Isobutylene | 10 | 0.05 | 0.8 | 45 | 2200x1600x1500 | 1000 |

| KVW-5/8 | Propane | 5 | Atmospheric Pressure | 0.8 | 37 | 2100x1600x1500 | 2000 |

| KVW-6.4/0.5-8 | Methyl Chloride | 6.4 | 0.05 | 0.8 | 55 | 2200x1500x1500 | 2500 |

| *Tips: 1.Other air delivery and pressure can be customized as per requirement. 2.The above parameters are subject to change, please ask your sales engineer. |

|||||||