Applications of Air Compressors in textile.

- Industrial revolution

The woven fabric portion of the textile industry grew out of the industrial revolution in the 18th century as mass production of yarn and cloth became a mainstream industry.

In 1734 in Bury, Lancashire John Kay invented the flying shuttle — one of the first of a series of inventions associated with the cotton woven fabric industry. The flying shuttle increased the width of cotton cloth and speed of production of a single weaver at a loom.Resistance by workers to the perceived threat to jobs delayed the widespread introduction of this technology, even though the higher rate of production generated an increased demand for spun cotton.[Source: wikipedia]

- 19th-century developments

The conditions were in place for the establishment of a mechanised textile industry in the 19th century.

From this point there were no new inventions, but a continuous improvement in technology as the mill-owner strove to reduce cost and improve quality. Developments in the transport infrastructure; that is the canals and after 1831 the railways facilitated the import of raw materials and export of finished cloth.

The industrial revolution changed the nature of work and society The three key drivers in these changes were textile manufacturing, iron founding and steam power.

- 20th-century developments

Major changes came to the textile industry during the 20th century, with continuing technological innovations in machinery, synthetic fibre, logistics, and globalization of the business.[Source: wikipedia]

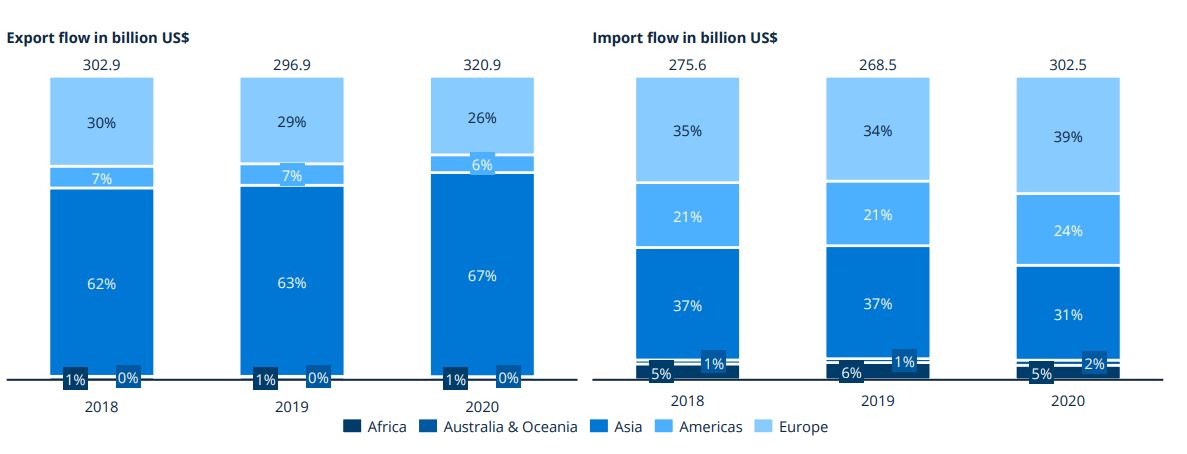

For “Manufacturing: Textiles”, Europe and Asia are the biggest trade partners

The Advantages of Air compressor in the textile industry

Air compressors are an essential part of a modern textile industry. They offer a range of advantages that can enhance efficiency, reduce costs and improve the quality of products.

One of the primary benefits of air compressors is their cost-effectiveness. Compressed air can help reduce the costs associated with yarn and fabric production. By using the latest technology, businesses can make the most of their resources, ensuring the production of high-quality fabrics and products.

Air compressors can also help to increase productivity in the textile industry. By using compressed air, manufacturers can reduce the time taken to make their products, resulting in higher levels of efficiency.

Finally, air compressors are an important part of waste management. Compressed air helps to reduce the amount of unnecessary waste produced during production. This makes air compressors an excellent choice for companies looking for sustainable solutions.

In conclusion, air compressors offer many advantages to the modern textile industry. They can help to reduce costs, increase productivity, and manage waste production. By utilizing the latest technology, businesses can ensure they are making the most of their resources, resulting in the production of high-quality fabrics and products.

Are you looking for a reliable and efficient power source for your textile industry? Kotech dealers are experienced in finding the perfect air compressor for your needs.

Contact your local Kotech dealer today and discover how an air compressor can increase your productivity and safety.

Factors affecting Efficiency of Air compressor in textile industry

Air compressors are a vital part of the modern textile industry and can provide a range of advantages to businesses. However, in order to make the most of their air compressors, companies need to understand the factors that can affect their efficiency.

- Temperature

One of the biggest factors is temperature. High temperatures can cause air compressors to overheat, reducing their efficiency and damaging their components over time. Therefore, it is important to ensure that air compressors are installed in a well-ventilated area to keep them running at optimal performance.

- Maintenance

Another factor to consider is maintenance. Regular maintenance and service of air compressors are essential to keep them running efficiently and avoid costly breakdowns. It is also important to ensure that air compressors are regularly checked for any signs of wear and tear, as this can reduce their efficiency if left unchecked.

- Quality

Finally, the quality of the air compressor is important. Investing in a high-quality unit will ensure that it runs at optimal performance for longer.

In conclusion, there are a number of factors that can affect the efficiency of air compressors in the textile industry. Companies should ensure that their air compressors are installed in a well-ventilated area, regularly serviced, and of high-quality in order to maximize their efficiency and availability.

Compressed Air’s Role in the Textile Industry

Compressed air is an essential part of the textile industry.

- Used to power airjet looms, spinning machines, ginning mills, and other industrial equipment.

- Used to add texture to fabrics and other details that increase the value of the finished product.

- Used to power tools that keep facilities clean and equipment working its best.

With the ever-evolving textile industry, manufacturers are continually looking for ways to improve the efficiency of their processes with the use of new equipment, and compressed air is a key element that helps them to achieve this.

When it comes to choosing the right air compressor for the textile industry, Kotech Compressor has the perfect solution. Our compressors are designed to provide reliable and consistent air pressure, while also offering low noise levels. Our air compressors are also energy efficient and can be used with a variety of machines and processes, including weaving looms, spinning machines, dyeing and finishing machines, and pneumatic tools.

We offer a variety of air compressors to meet the needs of the textile industry, including oil-free, oil-lubricated, and high-pressure models. Our compressors are designed for durability and can withstand the harsh conditions of the textile industry. They are also easy to install and maintain.

At Kotech Compressor, we are committed to providing our customers with the best air compressors for the textile industry. We offer a wide range of air compressors to meet any need, and our knowledgeable team of professionals can help you select the right compressor for your application. Contact us today to learn more about our range of air compressors for the textile industry.

For the highest quality products than can withstand the heavy-duty demands of any mining operation, take a look at these recommended compressor models: