Rotary screw air compressor( including oil flooded air compressor) is an air compressor that uses two spiral screws or rotors to compress air. It is a positive displacement compressor, which means it captures a specific volume of air and then reduces that volume to increase air pressure. Widely used in various industrial and commercial fields due to their efficiency and reliability.

Air compressors play an important role in industrial applications and screw air compressors are one of the efficient options. Here we will introduce the Kotech oil-injected air compressor series.

We Have Three Products Series for Choose!

Discover our comprehensive range of oil flooded air compressor solutions, including the high-performance KFU Series, versatile KES Series, and cost-effective KOE and KOE II Series, all meticulously designed to meet diverse industrial needs.

KES Series

(Oil-injected screw air compressor with siemens parts )

Multi-functional design with compatibility for Siemens electric motor, Siemens PLC, Siemens controller, and Kotech Air-End.

Integration with Siemens components ensures advanced and reliable performance.

Ideal for various industrial applications with versatile functionality, catering to international markets with diverse industrial requirements. This includes manufacturing, hydraulic engineering, power plants, oil refineries, and more.

Energy Savings in Every Detail

- Energy Saving Motor

- High Efficiency Controller

- Excellent Cooling Effect

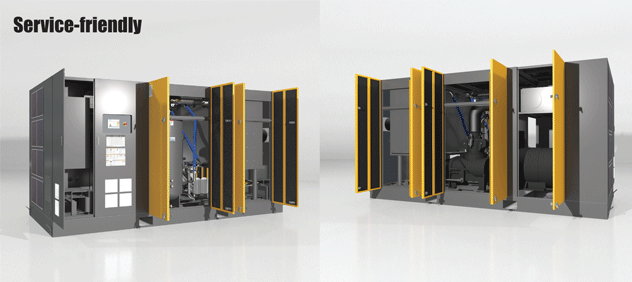

AirCare – Flexible Maintenance

AirCare is a fast-responding and flexible maintenance program provided by KOTECH compressor, which provides customers with the necessary repair services according to their needs.

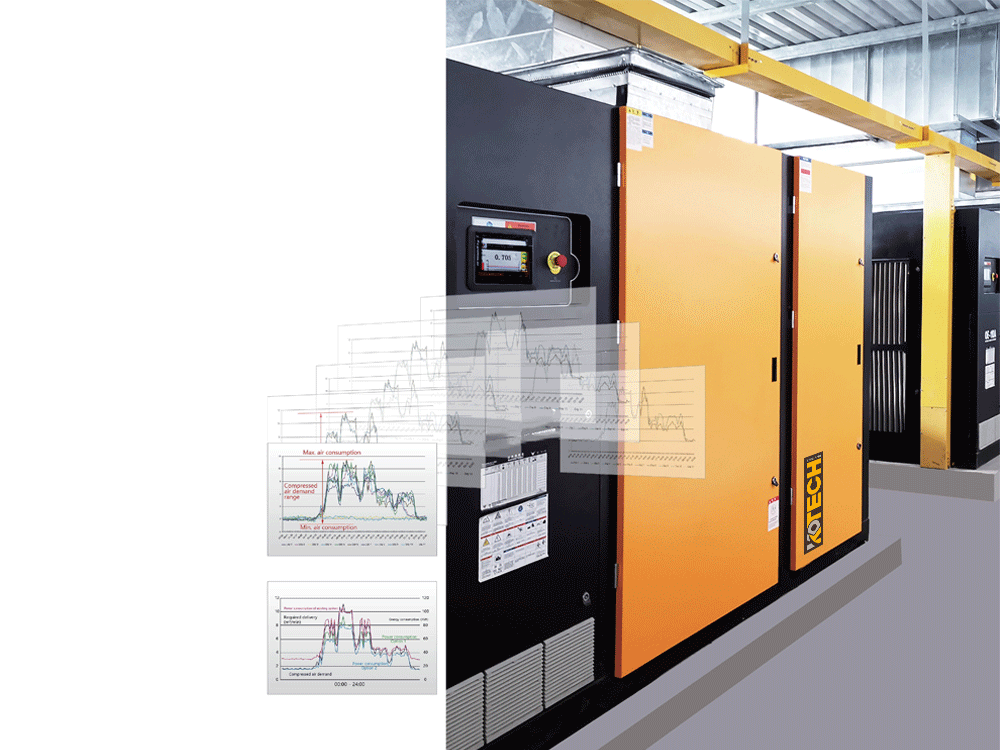

System Cost Control

After learning the customer, s actual air demand and operation conditions, we will consider all relevant parameters for you including required pressured, delivery capacity, air quality, system performance and energy consumption.

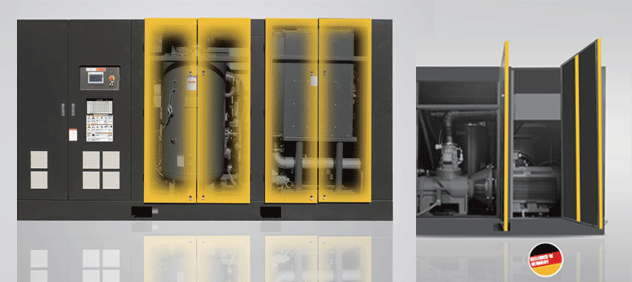

KFU Series

(Rotary Screw Air Compressor with High-end Siemens Brand Parts)

Premium-grade two stage air compressor designed to work seamlessly with Siemens components.High-end performance and durability for demanding industrial environments.

The KFU series of screw variable speed compressors range from 3 hp to 420 hp. They can be equipped with high-end components such as Siemens motors, Siemens PLC, GHH Air Ends and can be customised to any size requirement. (Working pressure from 6 – 12.5 Bar)

Specializing in custom design and installation services for any size oil-lubricated & oil-free air compressors, blower, cooler or cooling water system.

The Kotech KFU series two stage air compressors are particularly suitable for applications requiring stable, continuous air pressure flow, such as production lines, automotive manufacturing and the food & beverage industry.

KOE Series

(Industrial Screw Air Compressor with China brand parts)

Focus on cost-effectiveness with a main emphasis on national production, offering a multi-choice between single stage air compressor and two stage air compressor to cater to diverse needs. High performance at an affordable price point, ensuring a competitive edge.

Provides a balance between quality and affordability for a wide range of applications. The KOE series offers a wide range of options to meet your specific needs, with power range from 2.2 KW to 355KW.

Industrial Screw Air Compressor Heat Recovery

Heat Recovery Rate

PWT heat exchanger system

KOE II Series

(Industrial Multi Stage Air Compressor)

KOE II Series is a two stage air compressor, featuring a dual compression process for enhanced efficiency.

The two stage air compressors possess higher working pressure than the single ones.

Two Stage Air Compressor vs. Single Stage:

Efficiency:

Two-stage compressors generally exhibit higher efficiency in handling varying loads.

Pressure Output:

Two-stage compressors provide higher pressure levels compared to single-stage compressors.

Application Range:

Single-stage compressors are suitable for applications with lower pressure requirements, while two-stage compressors are designed for higher pressure demands.

Energy Efficiency:

Two-stage compressors are often more energy-efficient in applications requiring higher pressures.

The Kotech KOE II series represents a high-performance variable-speed rotary screw compressor unit, finding versatile applications across a spectrum of industries.

Ranging from 3 horsepower to 420 horsepower, all KFU、KOE II units within this series boast industry-leading efficiency and ease of maintenance.

K Series Rotary Screw Air Compressor 5 Advantages:

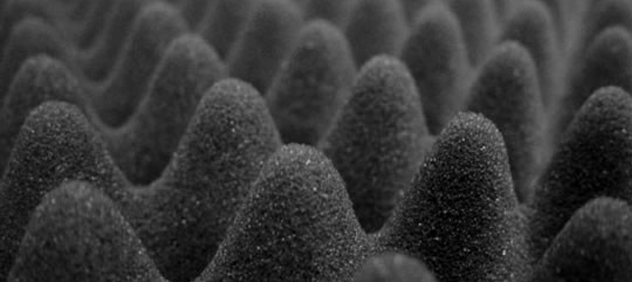

Lower noise:

Using Space insulation cotton reduces more noise,workers can have a good working environment.

Applications for Industrial Oil Lubricated Air Compressors

Industrial oil-lubricated air compressors find a wide range of applications across various industries due to their efficiency and reliability. Some common applications include:

Looking for Reliable High-Quality Air Compressors? Choose KOTECH!

Looking for Reliable High-Quality Air Compressors? Think KOTECH!

To order a Kotech compressor system, please contact us. Or you want to become our distributor, you can also contact us to become a Kotech compressor distributor.

To order a Kotech compressor system, please contact us. Or you want to become our distributor, you can also contact us to become a Kotech compressor distributor.

Looking for Reliable High-Quality Air Compressors? Choose KOTECH!

Looking for Reliable High-Quality Air Compressors? Think KOTECH!

To order a Kotech compressor system, please contact us. Or you want to become our distributor, you can also contact us to become a Kotech compressor distributor.

To order a Kotech compressor system, please contact us. Or you want to become our distributor, you can also contact us to become a Kotech compressor distributor.