Applications of Air Compressors in Medical.

Air Compressor in the Medical

Pioneering Medical Compressed Air

The role of compressed air in medical gases is a crucial aspect in the medical field. Starting with the (mechanical) vacuum pump made in Germany in 1640 AD, air compressors have undergone a major transformation from oil-lubricated to oil-free lubrication.

However, after compressed air is compressed at high temperature and high pressure, a large amount of water will be produced, leading to problems such as excessive water accumulation in the air tank and excessive microorganisms in the compressed air.

If oil-lubricated air compressors are named the first generation of medical compressed air systems and oil-free lubricated air compressors are named the second generation of medical compressed air systems, then the system that can provide oil-free, clean, and dry compressed air will be called the third generation of medical compressed air systems. With the advancement of industrial technology, a revolutionary breakthrough in air compression technology occurred in the early 20th century.

Mechanical compressed air has been widely used, and air compressors have gradually become an important power source for medical equipment and operating rooms, and have led to the emergence of a number of new medical methods and tools. >>Know more about air compressor types

- Our Unwavering Dedication:

At Kotech, we are steadfastly committed to propelling the domain of compressed air within the oil free medical industry forward. Our state-of-the-art technology and inventive solutions are meticulously crafted to ensure that your medical environment consistently upholds the highest echelons of air quality.

Exploring Vital Applications of Medical Air Compressors:

Medical institutions rely on medical air for various applications, tailored to the unique requirements of each sector. Primarily serving as a readily available and secure source of oxygen, this compressed air ensures a continuous, contaminant-free supply for hospitals and healthcare facilities. It remains free from impurities, particles, oils, odors, and moisture. The utilization of medical air in each healthcare sector is intricately tied to its daily operations and the specific needs of patients.

Below are three common uses for compressed medical air:

1. Ventilators: Elevating Respiratory Support

Ventilators stand as a cornerstone in medical-grade compressed air applications(medical air compressor for ventilators), providing patients with a safe and compressed supply of medical air. Widely utilized in surgeries, intensive care units (ICUs), COVID-19 treatments, and neonatal wards, these devices ensure enhanced oxygen supply and patient comfort. The precision of air compressors reduces the risk of respiratory infections, fostering a cleaner and safer breathing assistance method.

2. Sterilization Processes: Ensuring Tool Sterility

Sterilization is paramount in healthcare, extending beyond traditional practices to laboratories, Pharmaceutical and dental equipment. Compressed air aids in drying processes, mitigating contaminants and particles to maintain sterile tools. This hands-free system reduces the risk of equipment contamination before use, ensuring medical professionals have access to impeccably clean tools for optimal patient care.

3. Equipment Power: Precision and Reliability

Air compressors serve as precise and reliable power sources for various medical tools and equipment. Ensuring a clean air supply, they prevent dirt and oil buildup, preserving the efficiency and lifespan of critical instruments. In hospitals, compressed air powers adjustable features in hospital beds, offering comfort to patients and facilitating accessibility for healthcare providers.

Additionally, it is indispensable in creating dry environments for dental tools during hygiene visits and supporting medical teaching simulators, where simulations use compressed air to represent specific processes.

What is medical air compressor used for in hospitals?

As the power and gas source for ventilators

Air compressors can provide compressed air for various medical equipment such as ventilators and anesthesia machines to ensure their normal operations. Ventilators are indispensable equipment in intensive care units and operating rooms. They provide patients with oxygen/air mixed gases. By adjusting the flow and concentration of compressed air, the needs of different patients can be met, helping patients with breathing difficulties to breathe more smoothly.

Allowing patients to breathe enough oxygen effortlessly even in very fragile conditions is crucial for patients with respiratory diseases and those who need assisted breathing.

In addition, aspirators are also common equipment in hospitals, used to clear secretions from the trachea and respiratory tract and keep the respiratory tract open. The aspirator uses the high-pressure air provided by the air compressor to suck out the secretions and relieve the patient’s symptoms of breathing difficulties.

Medical gas system

Various gases are needed in hospitals, such as oxygen, nitrous oxide (laughing gas), argon, etc., and these gases generally need to be compressed into high-pressure gases by air compressors and then supplied to clinical departments through medical gas system.

For example, oxygen and laughing gas are needed during surgery, and these gases are usually manufactured, compressed into high-pressure gases by medical air compressors, stored in gas cylinders, and connected to the operating room for patients.

Oxygen production and supply

Medical air compressors can be used in the central oxygen supply system of hospitals. After filtering, purifying and compressing the air, they are supplied to wards, operating rooms, ICUs, etc. to provide oxygen, gas and air power for patients and various medical equipment. The medical air compressor in the central oxygen supply system has the advantages of fixed installation position and stable oxygen supply. It can ensure the normal operation of key areas such as operating rooms, wards and ICUs, and is the core of the entire system.

In addition, portable medical air compressors can also be used in emergency vehicles to provide oxygen for emergency medical equipment and ambulances, ensuring that necessary medical treatment can be provided to patients in a timely manner in emergency situations.

Cleaning and sterilization

Hospitals often need to do a lot of cleaning and disinfection work to ensure the sterility of operating rooms and various medical equipment. Sterilization is also paramount in healthcare, extending beyond traditional practices to laboratories, Pharmaceutical and dental equipment.

Medical compressed air aids in drying processes, mitigating contaminants and particles to maintain sterile tools. This hands-free system reduces the risk of equipment contamination before use, ensuring medical professionals have access to impeccably clean tools for optimal patient care.

And medical air compressors can provide compressed medical gas for disinfection and sterilization equipment, such as common steam sterilizers, high-temperature and high-pressure sterilizers, etc. Using compressed air to generate high-temperature and high-pressure steam can effectively kill germs and bacteria and keep operating rooms and medical equipment clean and safe.

Laboratory instrument gas supply

Hospital laboratories generally use a variety of instruments and equipment for research, analysis and experimental operations, and these equipment often require compressed air as a power source or to provide medical gas supply. For example, gas chromatographs, mass spectrometers, gas generators and other measuring instruments and control equipment in laboratories all require medical air compressors to provide compressed medical gas supply to ensure the normal operation of the instruments and equipment.

As the power source for various medical equipment and devices

Air compressors serve as precise and reliable power sources for various medical tools and equipment. Ensuring a clean air supply, they prevent dirt and oil buildup, preserving the efficiency and lifespan of critical instruments. In hospitals, compressed air powers adjustable features in hospital beds, offering comfort to patients and facilitating accessibility for healthcare providers.

Additionally, it is indispensable in creating dry environments for dental tools during hygiene visits and supporting medical teaching simulators, where simulations use compressed air to represent specific processes.

Many medical devices require compressed air as a gas source to work. For example, in the operating room, many surgical instruments require the use of compressed air. For example, scalpels, suture guns, etc. need to be driven by compressed air. Compressed air can provide precise power supply and sensitive response capabilities, ensuring the accuracy and efficiency of doctors in surgical operations.

In addition, air compressors can also provide a stable and reliable compressed air power source for medical tools such as blood gas analyzers and polymerase chain reaction instruments.

Are you looking for a reliable and efficient power source for your medical industry? Kotech dealers are experienced in finding the perfect air compressor for your needs.

Contact your local Kotech dealer today and discover how an air compressor can increase your productivity and safety.

What is the use of compressor in dental clinic?

Oral medical air compressor

Oral medical air compressor is a kind of equipment specially used for oral treatment and driving surgical tools. It is mainly used to provide high-pressure gas, water and vacuum suction to the dentist’s hand-held tools. It has the advantages of cleanliness, high efficiency and safety, and is an indispensable equipment in the modern oral and dental treatment process.

The role of oral medical air compressor

Gas supply: In dental treatment, oral medical air compressors are mainly used to provide high-pressure gas to hand-held tools. For example, in an aerosol toothbrush, the oral medical air compressor can compress the air to 4 bar to spray out oral cleaners, effectively removing bacteria from caries and periodontal disease. It can also be used to dry the surface of teeth, or to dry the moisture in the equipment, or to blow away the tooth powder that has been ground off by the dentist.

Water supply: The oral air compressor can also provide water to hand-held tools. For example, in the use of a toothbrush, it can supply water from the water tank to the nozzle to clean teeth and gums.

Vacuum supply: In dental treatment, the oral air compressor can also provide vacuum suction. For example, during treatment, the dentist may need to suck out the saliva in the mouth for treatment. At this time, the oral air compressor can provide negative pressure to help the dentist effectively suck out the saliva and broken tooth fragments in the patient’s mouth.

Specific application of air compressor in dental clinic

In oral treatment in hospitals and dental clinics. Due the high efficiency and safety characteristics of medical air compressor, it’s widely used in various oral treatment equipment such as dental pneumatic handheld drills, aerosol toothbrushes, tooth cleaners, electro-optical glaze machines and endodontic treatment devices, and have become an indispensable device in modern oral treatment. Take a dental pneumatic handheld drill as an example:

In the process of dental restoration treatment, pneumatic handheld dental drills are a treatment device frequently used by dentists, mainly used for tooth drilling, removing decay, etc. Its working principle is as follows:

The compressed air generated by the air compressor enters the drill bit through the air intake pipe, drives the turbine to rotate at high speed, drives the drill needle fixed in the upper and lower cards of the turbine to rotate at high speed, and the gas is discharged from the drill bit through the exhaust pipe. Inside the drill bit, the lower part is the cooling water passage, and the water flows from the right into the cavity under the head. Then it is sprayed out from the two water spray holes to achieve cooling of the drill bit.

Application of air compressor in rehabilitation and healthcare industry

Hyperbaric oxygen therapy

Medical oxygen compressors can provide high-purity and high-pressure oxygen, meet the needs of various medical equipment in rehabilitation and healthcare institutions and facilities, provide oxygen therapy services for patients, such as the common hyperbaric oxygen therapy, which is a treatment method that improves tissue hypoxia by providing patients with high-concentration oxygen. It is very important in treating various hypoxia-induced diseases such as brain hypoxia.

If a person breathes oxygen under high pressure, it can increase the physical dissolved oxygen content in the plasma, improve the supply and reserve of oxygen to the tissue, promote the body’s self-renewal process, enhance cell vitality, repair damaged tissues, fight diseases, and accelerate the healing process of patients. Hyperbaric oxygen therapy is an emerging clinical medical method.

It is a non-invasive, non-toxic treatment method that enhances the body’s ability to resist diseases and eliminate pain. In recent decades, with the rapid development of modern physiology, biochemistry and other scientific and technological fields, medical scientists have done a lot of research on the basic theory and clinical application of hyperbaric oxygen and achieved great results. Therefore, medical oxygen compressors are increasingly widely used in the medical and rehabilitation industries.

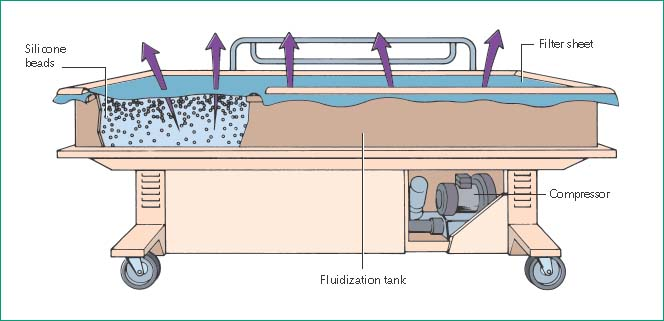

Air fluidized therapy bed

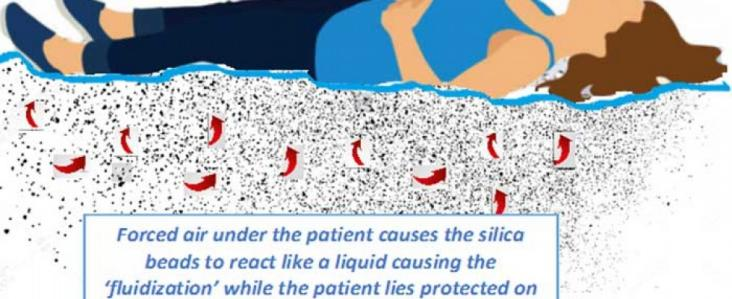

The medical air fluidized therapy bed is a new type of medical treatment equipment, which is widely used in many fields of medical treatment and rehabilitation. It is the most advanced equipment in the rescue of burn patients, and has significant effects on the treatment and rehabilitation of patients with burns and bedsores.

It looks like a large bathtub, and very fine particles are placed in the tank to form a particle bed. The filling height of the particles is about 30 cm, and there is a breathable porous plate under the particles, which makes the medical compressed air evenly distributed. When the filtered compressed air flows upward through the fine particles(each grain of particle is only 50-150 microns in diameter, the particles act as an intermediary between the bed and human body), the particles will flow like water and can generate considerable buoyancy, enough to make the patient float on the flowing particles.

This bed relies on medical compressed air flow and suspending particles to suspend the patient, so it is called a pneumatic particle suspension bed.

(Image source: nursekey.com)

When the patient floats on the flowing particles(Fluid pressure≤14mmHg), the contact area between the human body and the particles is quite large, while the pressure per unit contact area is very small, which will increase the blood flow in the contact area of the human skin, improve the nutrition of the skin surface and tissues, and accelerate the growth and healing of the skin and tissues.

For patients with large-area or whole-body burns, the less pressure per unit contact on the injured skin surface and tissue means less pain for the patient and makes the patient feel comfortable. When the patient floats on the flowing particles, there is no dead angle on the contact surface between the human body and the particles. A proper amount of clean air flows through the surface of the human body, and the secretions of the wound can flow into the bed and dry the wound in time, greatly improving the condition of the wound surface and facilitating wound healing.

Patients who have been bedridden for a long time are very likely to develop bedsores, which can cause great pain to the patient. If the patient lies on a suspended bed, the circulating air and soft support will not only prevent the patient from developing bedsores, but also treat bedsores.

(Image source: homecaremag.com)

In addition, the application of high-pressure air compressors also includes the field of basic patient care. For example, pneumatic medical beds, mattresses, and seats all require high-pressure gas. The wide application of air compressors in the medical and rehabilitation industries enables patients to obtain better care experience and rehabilitation effects. In the future, the use of air compressors in the medical and rehabilitation industries will become more and more common.

What kind of air compressor is used in hospitals?

Types of Medical Air Compressors Used in the Industry:

Oil Free Dry Screw Air Compressor:

- Advantages: Higher air output, lower maintenance than reciprocating compressors.

- Disadvantages: Initial cost.

- Reliability: Analyze preventive maintenance practices to enhance reliability and minimize downtime.

Oil Free Scroll Air Compressors:

- Advantages: Minimal vibration, quieter operation, suitable for clean room applications.

- Disadvantages: Limited air output for high-demand processes.

- Maintenance: Reliability is further enhanced through proactive maintenance practices, ensuring minimal downtime and optimal performance in medical settings.

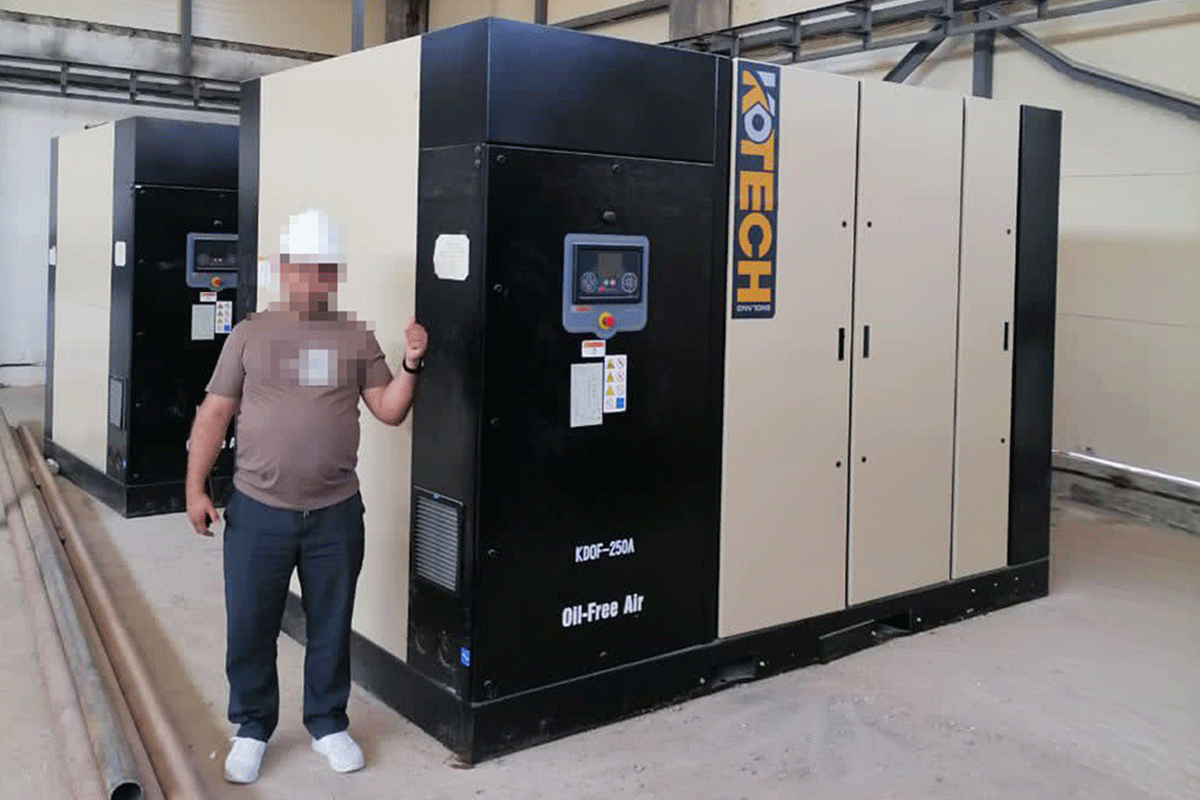

Breathing Easier: A Case Study on the 250kW Oil-Free Air Compressor

Challenge:

We are proud to have been able to solve an industrial oil-free air compression requirement for our customers. The KDOF series 250kw oil-free dry screw air compressors are cleverly used in oil-free applications.

Implementation:

Enhanced sterility: The KDOF series ensures oil-free compressed air delivery to the highest standards of sterility.

In view of the characteristics of the medical industry and healthcare industry, such as long machine operation time, no shutdown, large compressed medical gas consumption,combined with the demand for stable, clean and oil-free gas source, Kotech’s permanent magnet single-stage low-speed low-pressure series, permanent magnet two-stage low-pressure series, and intelligent permanent magnet variable frequency medical air compressor are all ideal choices.

In the after treatment equipment, precision filters and cold dryers are configured for purification. The dew point value of the treated compressed air can reach -70 degrees, the filtration accuracy is 0.01μm, and the index of impurity particles, oil-free, and water-free all meet international standards, meeting the continuous compressed medical gas demand of the medical industry and healthcare industry. Contact us now to learn more!