Applications of Air Compressors in Painting.

Introduction:

Industrial spray painting is a widely used technique in various industries, serving as a crucial process for applying a uniform and protective coating to surfaces. It plays a vital role in enhancing aesthetics, improving corrosion resistance, and ensuring product durability.

From automotive manufacturing to aerospace, from metal fabrication to furniture production, industrial spray painting is employed across diverse sectors to achieve high-quality finishes and meet stringent quality standards.

When it comes to achieving a flawless paint finish, the right tools make all the difference. At Kotech Compressor, we understand the importance of using high-quality air compressors for painting projects. Our air compressors are designed to deliver consistent, clean, and reliable airflow, ensuring that your painting endeavors yield outstanding results every time.

What are the roles and key usage points of compressed air systems in automotive painting?

1. The role and key points of use of compressed air systems

Compressed air is mainly used to convey paint, atomize paint, drive pneumatic tools, blow dry moisture and dust, drive pneumatic valves and so on in the production process of automobile painting.

The usage points of compressed air include process usage points, tooling and equipment usage points. The main process usage points include: paint mixing station, spray painting station, spray gun usage point, blow cleaning station, polishing station (pneumatic polishing machine usage point), gluing station (glue gun usage point), polishing station (pneumatic polishing usage point), etc.

The spray gun is a key part of compressed air usage; The main usage points of tooling equipment include: tooling installation and disassembly stations (pneumatic wrench usage points), etc.

2. Composition of compressed air system

The main equipment and facilities of the compressed air system in the spraying industry include air compressors, main lines, branch lines, storage tanks, adsorption dryers, filters, oil-water separators, adsorption oil-water separators, regulators, pressure gauges and so on.

(1) Integrated air compressor: At present, it mainly consists of permanent magnet motors and twin-screw compressors, and their models are selected based on the daily spraying vehicles in the factory. The displacement of air compressors is 10m3/min, 20m3/min, 40m3/min, and the exhaust pressure is mostly 0.8MPa. Currently, the main models are permanent magnet frequency conversion oil screw air compressors and high-quality oil-free screw air compressors.

(2) The main pipeline is a compressed air delivery pipeline arranged in the factory building. Most of them are now set into a fully closed loop circuit, with the aim of ensuring constant pressure at each gas consumption point, and segmented isolation valves are set up for later maintenance and repair.

(3) A branch pipeline is a pipeline that leads from the main pipeline of the factory to the gas consumption point.

(4) The gas storage tank is a buffer pressure vessel installed on the gas system, which has the function of stabilizing air pressure and saving. The capacity is matched according to the gas consumption, and the material can be carbon steel or stainless steel.

(5) The adsorption dryer is installed at the inlet end of the compressed air into the coating production line or at the back end of the air compressor in the air pressure station. The water in the compressed air is analyzed by the adsorbent to achieve a certain drying effect, and its rated processing capacity is matched with the air compressor.

(6) The filter filters the compressed air conveyed by the air compressor and adsorption dryer, filters and discharges the oil and water in the compressed air, so that the purification level of the compressed air meets the requirements of the automotive spraying industry, with the aim of controlling the dust content in the compressed air.

(7) The oil-water separator is installed on the branch pipeline to discharge the water and oil stains deposited in the compressed air pipeline system.

(8) The adsorption type oil-water separator is installed in the branch pipeline after the oil-water filter. In the front section of the gas station, it is commonly used in the spray painting station and the cleaning station before painting. The activated carbon inside can further effectively remove dust, oil stains, and particulate impurities contained in the compressed air.

(9) The regulator valve and pressure gauge are used to adjust and display the pressure of compressed air.

3. Quality level of compressed air

Because the air compressor needs to compress the air in the atmosphere, according to the principle of energy conservation, part of the electrical energy will be converted into heat to raise the air temperature to more than 100 ℃. The moisture and oil in the compression process will be mixed with compressed air, so the compressed air needs to be removed from the compressed air during the use of moisture, dust and oil.

The method is to achieve the compressed air quality requirements for automotive painting after being treated by a freeze dryer and oil-water separator: the pressure dew point should not exceed -40 ℃, the dust content should be less than 0.5-1um, and the oil content should be less than 0.1mg/m3.

The principle of the spray gun matched with the air compressor: when compressed air is discharged from the pores of the hood, a negative pressure is formed at the nozzle of the paint, which exerts suction force on the paint.The types of spray guns are gravity type, suction type, pressure feeding type.

The main drawback of spraying operations is the generation of shrinkage holes, which are caused by the mixing of pollutants (dust in the air, internal pollutants, oil stains in the air, and other objects with different surface tensions) into the coating layer.

Because the initiator of the shrinkage cavity must be a low surface tension substance, while the acceptor of the shrinkage cavity is a high surface tension substance, when the low surface tension substance reaches the coating, a surface tension gradient is formed, showing a stretching trend, causing it to diffuse from the center to the surrounding areas.

Are you looking for a reliable and efficient power source for your textile industry? Kotech dealers are experienced in finding the perfect air compressor for your needs.

Contact your local Kotech dealer today and discover how an air compressor can increase your productivity and safety.

Gas Humidification

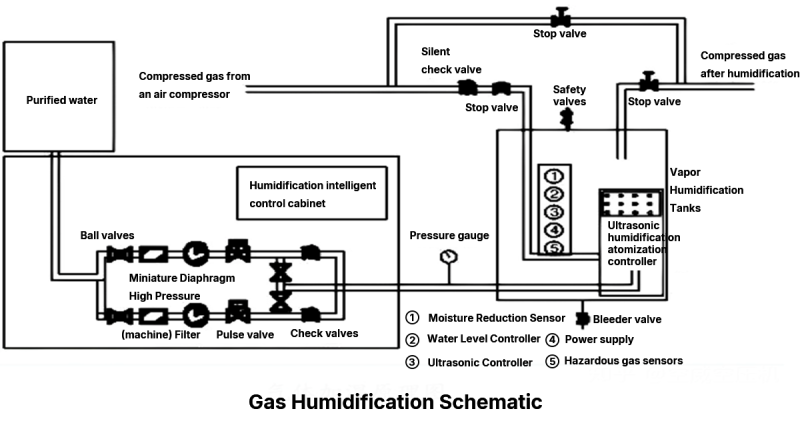

Humidification principle and process: humidification of the gas in the compressed air pipeline, and adjustable.

Referring to the medical humidification device, the air pipeline from the compressor is divided into 2 branches, one pipe passes through the pure water humidification tank for humidification, and the other pipe passes through the bypass; the two pipelines merge at the outlet of the humidification tank.

Each pipeline through the flow valve to control the air flow, respectively, through the control of drying, humidification of the air flow and thus control the humidity of the air in the pipeline.

Design level meter and alarm device, in the humidification tank at the bottom of a drain valve, the tank of residual water can be regularly replaced and internal cleaning.

Barrels of pure water purified water using level control automatic replenishment, through the addition of electronic detection equipment to achieve the level of visual, level alarm, adjustable humidity, harmful gas detection function.

In accordance with the volume of humidification equipment, every 3-4 workstations with a set of principles, compressed air into the humidification equipment before the addition of a pressure reducing valve to ensure that the compressed air into the humidification equipment adjustable pressure.

Humidification equipment should have a device to prevent water from flowing into the air pipeline.

Kotech Products in Action

We are able to provide air compression solutions for the painting 、sandblasting、mining、construction industry……and a professional after sales team 24/7 Support Service.

- After-sales Service

Free on-site training for field managers and operators.

Responsible for onsite installation instructions and commissioning of the startup.The file is created after the productleaves the factory, and the “regular user return visit” system is implemented.

lf equipment failure is encountered, the after-sales service engineers will respond within 5 minutes after receiving thecustomers notice, and dispatch the after-sales service personnel to the customer’s site as soon as possible according tothe fault situation to ensure the normal production.

For the highest quality products than can withstand the heavy-duty demands of any mining operation, take a look at these recommended compressor models: