KT Series

20 - 40 Bar Middle Pressure PET Piston Air Compressor

Kotech Compressor has developed an integrated armoured equipment specifically designed for medium-pressure laser cutting, catering to the metal and laser industries.

The system is equipped with 1.2m3/min@30bar compressed air, air tank ranging from 130L to 1000L (optional), stainless steel plate for freeze dryer, lower pressure dew point, 5-stage precision filter and centralized electronic sewage disposal, ensuring the cleanness of the cutting gas source.

Social Sharing:

○ Valve materials are made of Sweden stainless steel band.

○ In order to ensure that air compressor highly reliable, using a redundant design principles, setting multiple protection measures: unloading, down drain, exhaust, ensure that the zero-pressure start.

○ Timed drain valve: Drainage and drainage at a time interval can be adjusted. Ensure that the captain of an air compressor runs continuously between regular drainage, effectively preventing water too much liquid strike accidents.

○ High reliability and long maintenance period, very low fuel consumption, low energy consumption and so on, greatly reducing the overall general operating costs.

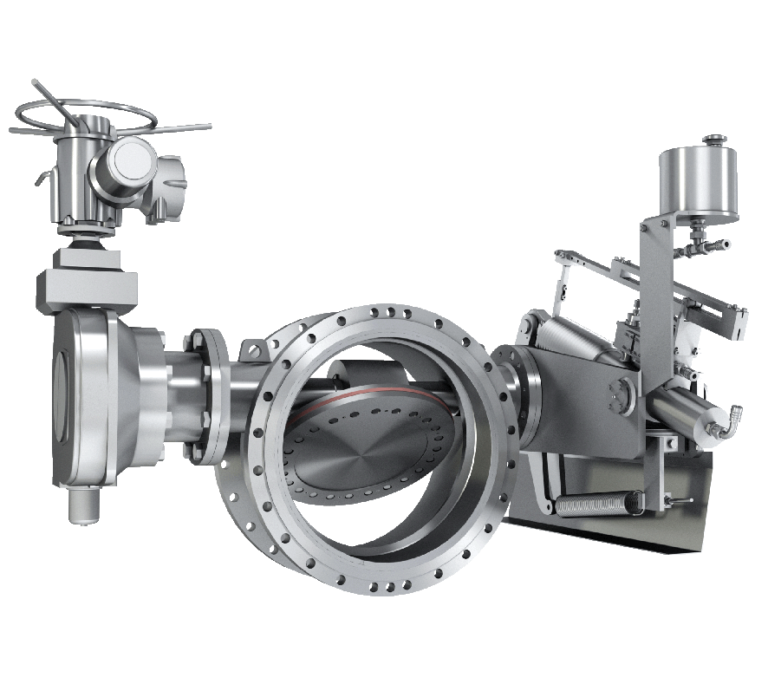

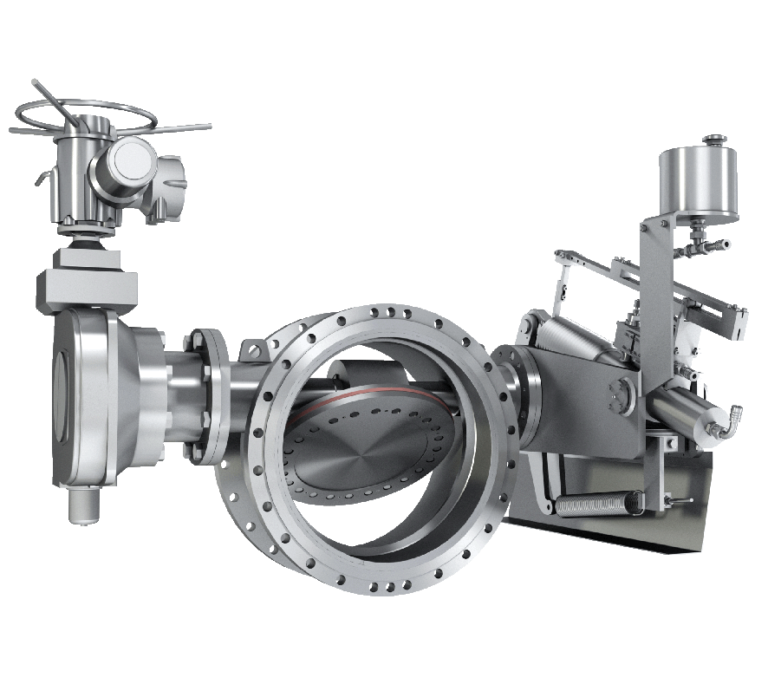

Combination valve patented technology

- Kotech combined air valve is the special kind of high efficient energy-saving and long life new combination air valve.

- Structure by into trachea-shaped valve and exhaust valve combinations, the main features below :air through the intake manifold valve cavity, along the tangent of the valve flow, impact of approximate straight lines, air valves and flow resistance greatly reduces, so it could provide low noise, long service life.

- Because of the inlet valve inside the vertical spatial distribution, inlet of the valve flow area increased, the valve flow rate and lower drag coefficient, aspiratory volume increase volume efficiency, reduced energy consumption.

- Intake and exhaust valves is the reed valve and strip-type valves fixed unlimited free elastic beam opening and closing movements, without friction and clearance volume small so kotech combined air valve has excellent dynamic performance and reliability.

- Fuel consumption per hour less than 0.143/kw.

- High reliability and long maintenance period, very low fuel consumption, low energy consumption and so on, greatly reducing the overall general operating costs.

Design Features

1. Powerful big head design, good material utilization, strong design of main components, head size and weight are bigger than other manufacturers, high safety, low speed, especially suitable for heavy load, long term continuous operation, extremely high reliability and super long life.

2. Special heat dissipation design and airflow design, low exhaust temperature, not easy to accumulate carbon, high efficiency.

3. Adopting an annular valve group design, the valve plate material is Swedish stainless steel valve plate, and the valve group spring material is special spring steel wire imported by the valve from Japan, the valve plate does not bend during operation, which improves the performance of the valve. The life index is particularly good.

4. The piston ring is made of imported Japanese fittings, which is durable and non-oil-contaminated.

5. The crankshaft adopts high-frequency quenching, which is particularly wear-resistant.

6. The related moving parts are precisely balanced, the movement is particularly stable and the noise is particularly low.

7. The air filter element adopts imported filter paper, which has a good filtering and noise reduction effect and is durable.

8. The front end cover is specially designed with an oil barrier structure, the breathing valve is not out of oil, the oil consumption is particularly low, and the body is clean.

9. The flare angle of the exhaust copper pipe is reasonably designed and protected by a protective cover to avoid rupture and air leakage.

10. pressure switch, contactor, thermal relay ‘Schneider’ and other imported brands to ensure reliable control and protection.

11. In terms of air volume control, there are four modes for users to choose from: full-automatic air volume control, full-automatic electric control, dual-use air control and electric control (manual switching) and intelligent control (automatic switching of electric control according to the amount of air consumption) to meet the different needs of users.

12. An intelligent controller can be installed optionally to meet the user’s complex gas conditions.

13. because of the relatively high-pressure ratio of the medium-pressure machine, a specially designed intercooler with a strong cooling capacity is used to maintain a low exhaust temperature.

| Model | Unit Model | Air Delivery (m3/min) |

Suction Pressure (Mpa) |

Compressed Stages |

Motor Power (Kw) |

Speed r.p.m |

Size(L*W*H) (mm) |

Weight (kg) |

| 63KT | KT-2.0/30 | 2.0 | 3.0 | 3 | 22 | 620 | 2178*1060*1060 | 690 |

| 2I-KT-2.0/30 | 4.0 | 2*22 | 3718*1108*1208 | 1380 | ||||

| 2-KT-2.0/30 | 4.0 | 2*22 | 2168*1058*2008 | 1380 | ||||

| 3-KT-2.0/30 | 6.0 | 3*22 | 5608*1108*1208 | 2070 | ||||

| KT-2.0/40 | 2.0 | 4.0 | 22 | 2178*1060*1060 | 690 | |||

| 2I-KT-2.0/30 | 4.0 | 2*22 | 3718*1108*1208 | 1380 | ||||

| 2-KT-2.0/30 | 4.0 | 2*22 | 2168*1058*2008 | 1380 | ||||

| 3-KT-2.0/30 | 6.0 | 3*22 | 5608*1108*1208 | 2070 | ||||

| 62KT | KT-1.3/30W | 1.3 | 1.3 | 3 | 15 | 660 | 1700*830*1030 | 560 |

| 2-KT-1.3/30W | 2.6 | 2.6 | 2*15 | 660 | 1750*2000*1230 | 1128 | ||

| 3-KT-1.3/30T | 3.9 | 3.9 | 3*15 | 660 | 3470*1110*1610 | 1788 | ||

| 4-KT-1.3/30T | 5.2 | 5.2 | 4*15 | 660 | 4630*1110*1610 | 2278 | ||

| KT-1.6/30W | 1.6 | 1.6 | 18.5 | 720 | 1700*830*1030 | 560 | ||

| 2-KT-1.6/30W | 3.2 | 3.2 | 2*18.5 | 720 | 1750*2000*1230 | 1160 | ||

| 2-KT-1.6/30T | 4.8 | 4.8 | 3*18.5 | 720 | 3470*1110*1610 | 1760 | ||

| 4-KT-1.6/30T | 6.4 | 6.4 | 4*18.5 | 720 | 4630*1110*1610 | 2380 | ||

| KT-1.3/40W | 1.3 | 1.3 | 15 | 660 | 1700*830*1030 | 560 | ||

| 2-KT-1.3/40W | 2.6 | 2.6 | 2*15 | 660 | 1750*2000*1230 | 1128 | ||

| 3-KT-1.3/40T | 3.9 | 3.9 | 3*15 | 660 | 3470*1110*1610 | 1788 | ||

| 4-KT-1.3/40T | 5.2 | 5.2 | 4*15 | 660 | 4630*1110*1610 | 2278 | ||

| KT-1.6/40W | 1.6 | 1.6 | 18.5 | 720 | 1700*830*1030 | 560 | ||

| 2-KT-1.6/40W | 3.2 | 3.2 | 2*18.5 | 720 | 1750*2000*1230 | 1128 | ||

| 3-KT-1.6/40T | 4.8 | 4.8 | 3*18.5 | 720 | 3470*1110*1610 | 1788 | ||

| 4-KT-1.6/40T | 6.4 | 6.4 | 4*18.5 | 720 | 4630*1110*1610 | 2278 | ||

| 61KT | KT-1.0/30 | 1.0 | 3.0 | 2 | 11 | 590 | 1450*750*1050 | 430 |

| KT-1.2/30H | 1.2 | 11 | 620 | 1450*750*1050 | 430 | |||

| 2-KT-1.0/30 | 2.0 | 2*11 | 590 | 1450*1700*1050 | 600 | |||

| 2-KT-1.2/30H | 2.4 | 2*11 | 620 | 1450*1700*1050 | 600 | |||

| KT-1.2/30 | 1.2 | 15 | 660 | 1450*750*1050 | 430 | |||

| 2-KT-1.2/30 | 2.4 | 2*15 | 660 | 1450*750*1050 | 600 | |||

| KT-1.2/30H-YQ | 1.2 | 11 | 620 | 1950*950*1300 | 570 | |||

| KT-1.2/30-YQ | 1.2 | 15 | 620 | 1950*750*1300 | 570 |

You May Also Like

KEH Series 30 – 50 Bar Middle Pressure PET Screw Air Compressor;

5 – 25m3/min

Working Pressure: 30 – 50bar

Learn More >>

KHW Series High Pressure Oil Free Piston Air Compressor

0.9 – 35m3/min

Working Pressure: 20 – 90bar

Learn More >>

KBC Series Scuba Diving Portable Breathing Air Compressor

100 – 750L/min

Working Pressure: 200 – 300Bar

Learn More >>

○ Valve materials are made of Sweden stainless steel band.

○ In order to ensure that air compressor highly reliable, using a redundant design principles, setting multiple protection measures: unloading, down drain, exhaust, ensure that the zero-pressure start.

○ Timed drain valve: Drainage and drainage at a time interval can be adjusted. Ensure that the captain of an air compressor runs continuously between regular drainage, effectively preventing water too much liquid strike accidents.

○ High reliability and long maintenance period, very low fuel consumption, low energy consumption and so on, greatly reducing the overall general operating costs.

Combination valve patented technology

- Kotech combined air valve is the special kind of high efficient energy-saving and long life new combination air valve.

- Structure by into trachea-shaped valve and exhaust valve combinations, the main features below :air through the intake manifold valve cavity, along the tangent of the valve flow, impact of approximate straight lines, air valves and flow resistance greatly reduces, so it could provide low noise, long service life.

- Because of the inlet valve inside the vertical spatial distribution, inlet of the valve flow area increased, the valve flow rate and lower drag coefficient, aspiratory volume increase volume efficiency, reduced energy consumption.

- Intake and exhaust valves is the reed valve and strip-type valves fixed unlimited free elastic beam opening and closing movements, without friction and clearance volume small so kotech combined air valve has excellent dynamic performance and reliability.

- Fuel consumption per hour less than 0.143/kw.

- High reliability and long maintenance period, very low fuel consumption, low energy consumption and so on, greatly reducing the overall general operating costs.

Design Features

1. Powerful big head design, good material utilization, strong design of main components, head size and weight are bigger than other manufacturers, high safety, low speed, especially suitable for heavy load, long term continuous operation, extremely high reliability and super long life.

2. Special heat dissipation design and airflow design, low exhaust temperature, not easy to accumulate carbon, high efficiency.

3. Adopting an annular valve group design, the valve plate material is Swedish stainless steel valve plate, and the valve group spring material is special spring steel wire imported by the valve from Japan, the valve plate does not bend during operation, which improves the performance of the valve. The life index is particularly good.

4. The piston ring is made of imported Japanese fittings, which is durable and non-oil-contaminated.

5. The crankshaft adopts high-frequency quenching, which is particularly wear-resistant.

6. The related moving parts are precisely balanced, the movement is particularly stable and the noise is particularly low.

7. The air filter element adopts imported filter paper, which has a good filtering and noise reduction effect and is durable.

8. The front end cover is specially designed with an oil barrier structure, the breathing valve is not out of oil, the oil consumption is particularly low, and the body is clean.

9. The flare angle of the exhaust copper pipe is reasonably designed and protected by a protective cover to avoid rupture and air leakage.

10. pressure switch, contactor, thermal relay ‘Schneider’ and other imported brands to ensure reliable control and protection.

11. In terms of air volume control, there are four modes for users to choose from: full-automatic air volume control, full-automatic electric control, dual-use air control and electric control (manual switching) and intelligent control (automatic switching of electric control according to the amount of air consumption) to meet the different needs of users.

12. An intelligent controller can be installed optionally to meet the user’s complex gas conditions.

13. because of the relatively high-pressure ratio of the medium-pressure machine, a specially designed intercooler with a strong cooling capacity is used to maintain a low exhaust temperature.

| Model | Unit Model | Air Delivery (m3/min) |

Suction Pressure (Mpa) |

Compressed Stages |

Motor Power (Kw) |

Speed r.p.m |

Size(L*W*H) (mm) |

Weight (kg) |

| 63KT | KT-2.0/30 | 2.0 | 3.0 | 3 | 22 | 620 | 2178*1060*1060 | 690 |

| 2I-KT-2.0/30 | 4.0 | 2*22 | 3718*1108*1208 | 1380 | ||||

| 2-KT-2.0/30 | 4.0 | 2*22 | 2168*1058*2008 | 1380 | ||||

| 3-KT-2.0/30 | 6.0 | 3*22 | 5608*1108*1208 | 2070 | ||||

| KT-2.0/40 | 2.0 | 4.0 | 22 | 2178*1060*1060 | 690 | |||

| 2I-KT-2.0/30 | 4.0 | 2*22 | 3718*1108*1208 | 1380 | ||||

| 2-KT-2.0/30 | 4.0 | 2*22 | 2168*1058*2008 | 1380 | ||||

| 3-KT-2.0/30 | 6.0 | 3*22 | 5608*1108*1208 | 2070 | ||||

| 62KT | KT-1.3/30W | 1.3 | 1.3 | 3 | 15 | 660 | 1700*830*1030 | 560 |

| 2-KT-1.3/30W | 2.6 | 2.6 | 2*15 | 660 | 1750*2000*1230 | 1128 | ||

| 3-KT-1.3/30T | 3.9 | 3.9 | 3*15 | 660 | 3470*1110*1610 | 1788 | ||

| 4-KT-1.3/30T | 5.2 | 5.2 | 4*15 | 660 | 4630*1110*1610 | 2278 | ||

| KT-1.6/30W | 1.6 | 1.6 | 18.5 | 720 | 1700*830*1030 | 560 | ||

| 2-KT-1.6/30W | 3.2 | 3.2 | 2*18.5 | 720 | 1750*2000*1230 | 1160 | ||

| 2-KT-1.6/30T | 4.8 | 4.8 | 3*18.5 | 720 | 3470*1110*1610 | 1760 | ||

| 4-KT-1.6/30T | 6.4 | 6.4 | 4*18.5 | 720 | 4630*1110*1610 | 2380 | ||

| KT-1.3/40W | 1.3 | 1.3 | 15 | 660 | 1700*830*1030 | 560 | ||

| 2-KT-1.3/40W | 2.6 | 2.6 | 2*15 | 660 | 1750*2000*1230 | 1128 | ||

| 3-KT-1.3/40T | 3.9 | 3.9 | 3*15 | 660 | 3470*1110*1610 | 1788 | ||

| 4-KT-1.3/40T | 5.2 | 5.2 | 4*15 | 660 | 4630*1110*1610 | 2278 | ||

| KT-1.6/40W | 1.6 | 1.6 | 18.5 | 720 | 1700*830*1030 | 560 | ||

| 2-KT-1.6/40W | 3.2 | 3.2 | 2*18.5 | 720 | 1750*2000*1230 | 1128 | ||

| 3-KT-1.6/40T | 4.8 | 4.8 | 3*18.5 | 720 | 3470*1110*1610 | 1788 | ||

| 4-KT-1.6/40T | 6.4 | 6.4 | 4*18.5 | 720 | 4630*1110*1610 | 2278 | ||

| 61KT | KT-1.0/30 | 1.0 | 3.0 | 2 | 11 | 590 | 1450*750*1050 | 430 |

| KT-1.2/30H | 1.2 | 11 | 620 | 1450*750*1050 | 430 | |||

| 2-KT-1.0/30 | 2.0 | 2*11 | 590 | 1450*1700*1050 | 600 | |||

| 2-KT-1.2/30H | 2.4 | 2*11 | 620 | 1450*1700*1050 | 600 | |||

| KT-1.2/30 | 1.2 | 15 | 660 | 1450*750*1050 | 430 | |||

| 2-KT-1.2/30 | 2.4 | 2*15 | 660 | 1450*750*1050 | 600 | |||

| KT-1.2/30H-YQ | 1.2 | 11 | 620 | 1950*950*1300 | 570 | |||

| KT-1.2/30-YQ | 1.2 | 15 | 620 | 1950*750*1300 | 570 |

You May Also Like

KEH Series 30 – 50 Bar Middle Pressure PET Screw Air Compressor;

5 – 25m3/min

Working Pressure: 30 – 50bar

Learn More >>

KHW Series High Pressure Oil Free Piston Air Compressor

0.9 – 35m3/min

Working Pressure: 20 – 90bar

Learn More >>

KBC Series Scuba Diving Portable Breathing Air Compressor

100 – 750L/min

Working Pressure: 200 – 300Bar

Learn More >>