KOE Series

Rotary Screw Air Compressor

● KOE: Kotech air end + Kotech electric motor

● KOE-XXG: Kotech air end + Siemens electric motor or Ingersoll Rand GHH air end + Kotech electric motor

● KOE-XXGS: Ingersoll Rand GHH air end + Siemens electric motor

● Certification: CE/ISO/ASME

● Air-cooled and Water-cooled

● Fixed Speed and Variable Speed Drive(VSD) Models

● Intelligent appearance, easy operation and maintainability

Social Sharing:

KOE Series Screw Air Compressor

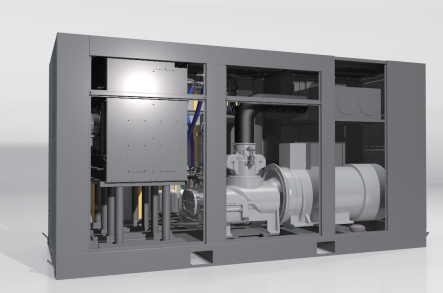

New generation design of KOTECH – more efficient partner

Power 2.2 to 355KW; Flow rate 0.2 to 70.35 m³/min; Pressure 7.5 to 13bar

KOE Energy Saving Standard

Through improved specific power, air flow optimization and further refinement of the rotor, excellent energy efficiency is achieved. Maximize energy efficiency with a high-performance IE4 drive motor.

Kotech’s 1:1 drive design eliminates the power loss associated with the original transmission and the gear or V-belt drive system. In addition, radial fans meet the efficiency requirements of the EU Directive 327/2011 for fans. But most importantly, the advanced compressor controller, through the use of a variety of specially developed control options, achieves additional energy savings and minimizes the cost of frequent downtime.

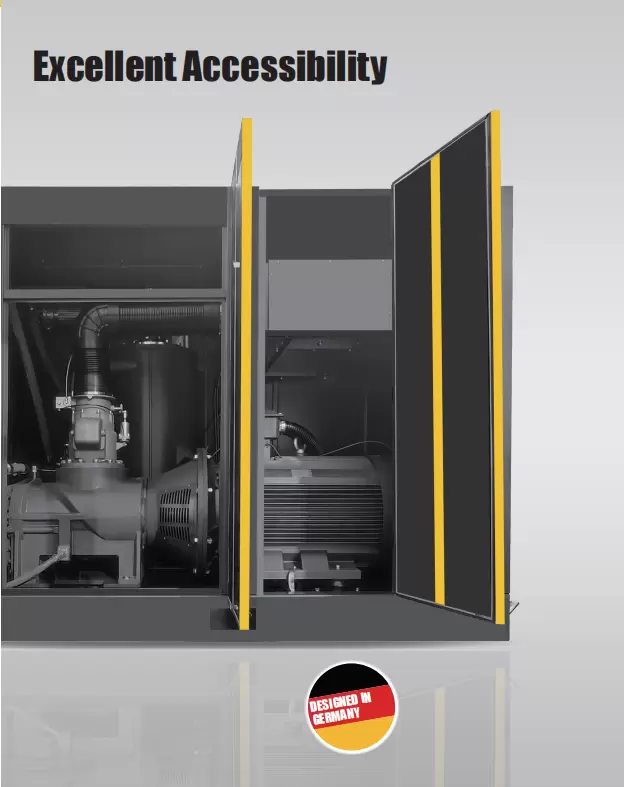

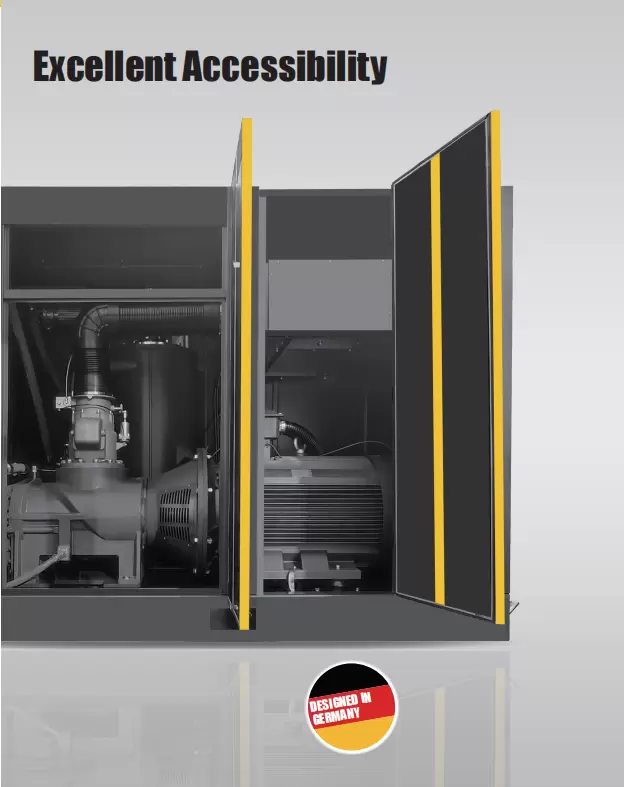

From the outside, the unique and striking design of these systems is complemented by the intelligent component layout inside for greater energy efficiency:

For example, all service and maintenance points are within reach and directly accessible from the front, which not only saves time and money, but also maximizes the availability of the compressed air system.

Intelligent Thermal Management System

The intelligent thermal management system will introduce the high-temperature circulating oil of the air compressor thermal water heater into the unit during operation, exchange it with water to heat up the water, and absorb the heat energy in the oil and gas to cool the air compressor, prevent the air compressor from skipping at high temperature, reduce the equipment failure rate, reduce maintenance, and ensure the safe supply of air compressor to industrial enterprises.

The intelligent thermal management system can help users obtain a large amount of hot water, save other heating energy, reduce enterprise operating costs, and respond to the word call for energy conservation and emission reduction, reduce carbon dioxide emissions, and reduce air pollution.

Why Choose Heat Recovery?

There is a great need to choose heat recovery, as most of the (electrical) energy input to the compressor is converted intoheat. Up to 96% of this energy can be recycled. This not only reduces primary energy consumption, but also significantly improves the company’s overall energy balance.

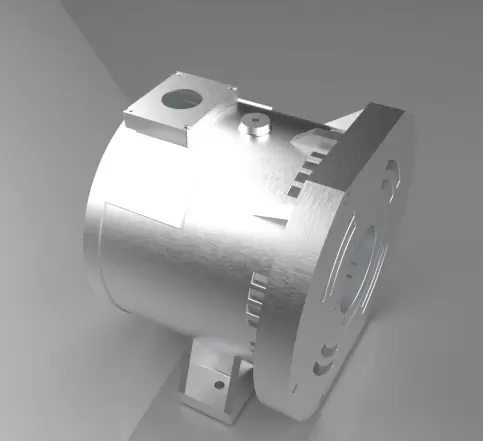

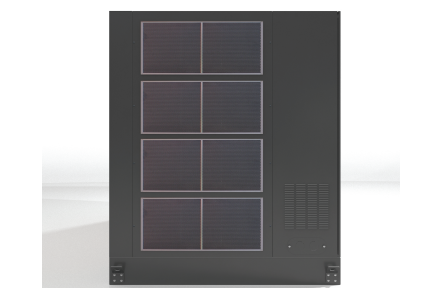

Energy Saving Motor

This series of motors is a new generation of energy saving products advocated and recommended by the

nternational market at present, and meet the high

altitude, harsh environment, overload requirements of

larger occasions, is the ideal supporting power KOE air

compression.

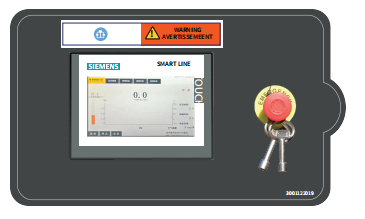

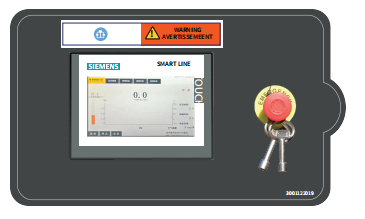

High Efficiency Controller

KOE controller integrated power frequency conversion, with arbitrary switching of working mode; Exhaust temperature detection; PID automatic adjustment of load rate control pressure balance and other functions; Main motor lack of phase, imbalance, overload, protection function; Phase sequence detection to prevent reversal; Temperature protection: When the actual temperature is detected greater than the set shutdown temperature, the air compressor stops; Machine maintenance information Settings, reminders, perfect fault protection; According to the setting, it can communicate with the upper computer and run in conjunction with other air compressors.

Excellent Cooling Effect

The most troublesome fault for the user of the air compressor is high temperature, and the two most direct solutions to avoid high temperature are to increase the fan power and sufficient cooler dirt coefficient.

Automatic Temperature Control Technology

A thermostatically controlled fan with a variable speed motor generates the precise amount of cooling air required by the fluid cooler to ensure a lower operating temperature.

This significantly reduces the overall energy requirements of the KOE screw compressor system.

Cold Compressed Air

Effective aftercooling helps keep compressor discharge temperatures low. This combined with a centrifugal separator, removes large amounts of condensate and then drains it through an electrically controlled condensate drain without energy loss and also reduces the burden on downstream treatment equipment.

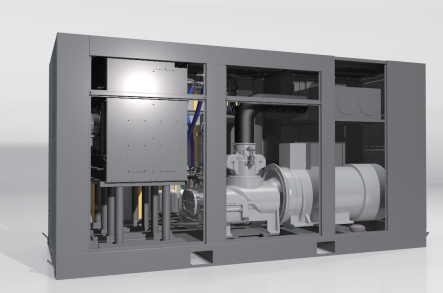

Clean Cooler from Outside

Unlike internally installed heat exchangers, externally installed coolers in KOE systems are easily accessible and easy to clean. As a result, operational reliability and availability are improved due to the ease with which contaminants can be prevented from accumulating.

High Residual Thrust for Exhaust

Integrated radial fans are much more efficient than axial fans and provide higher residual thrust. This allows the hot exhaust to be delivered directly through the pipe without the need for an auxiliary fan.

Kotech new generation of intelligent controllers , with their intuitive high-resolution, oversized color screens, are equipped with network connectivity to achieve higher levels of communication, connectivity and control, greatly enhancing the actual productivity of the air compressor.

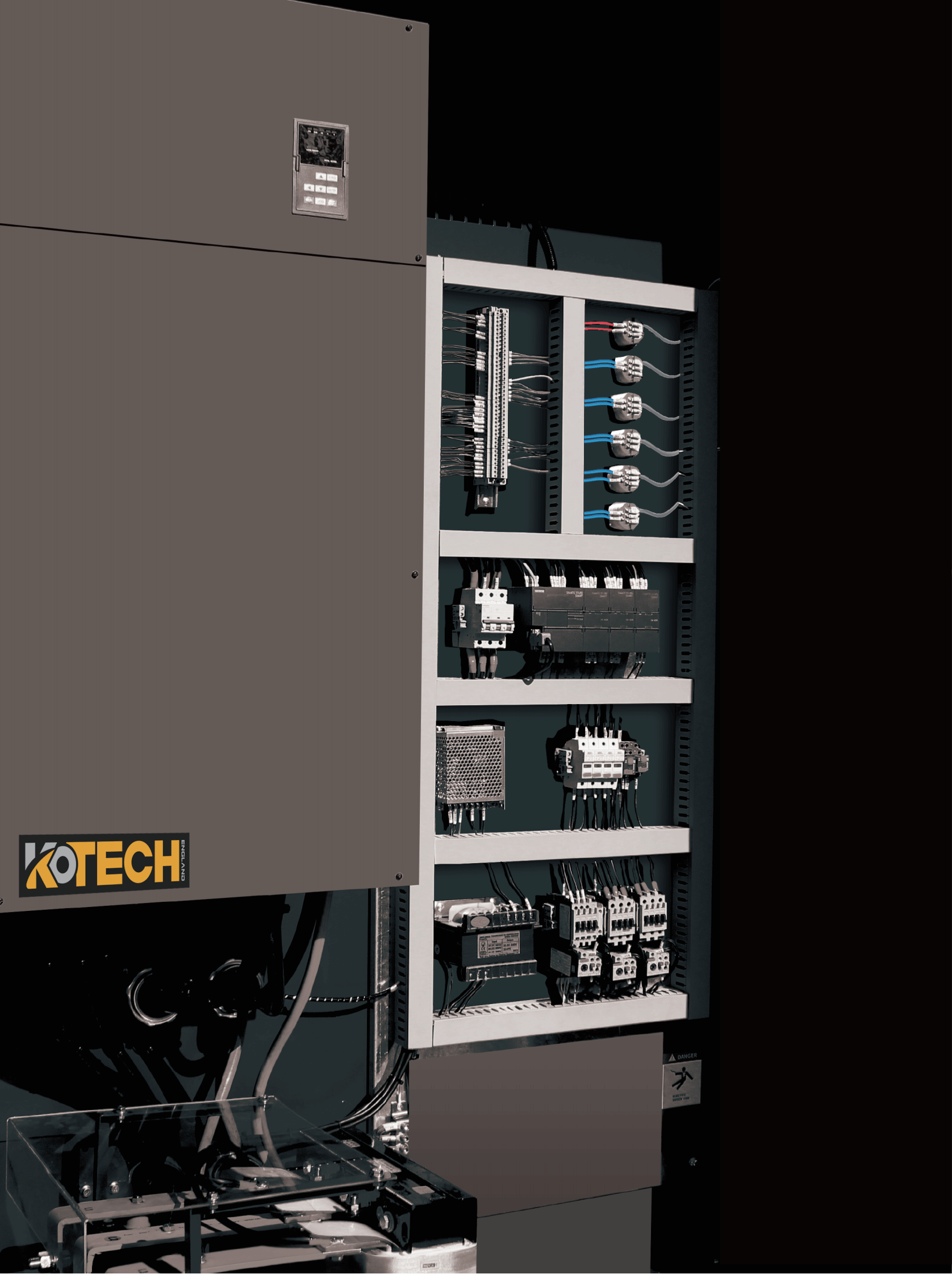

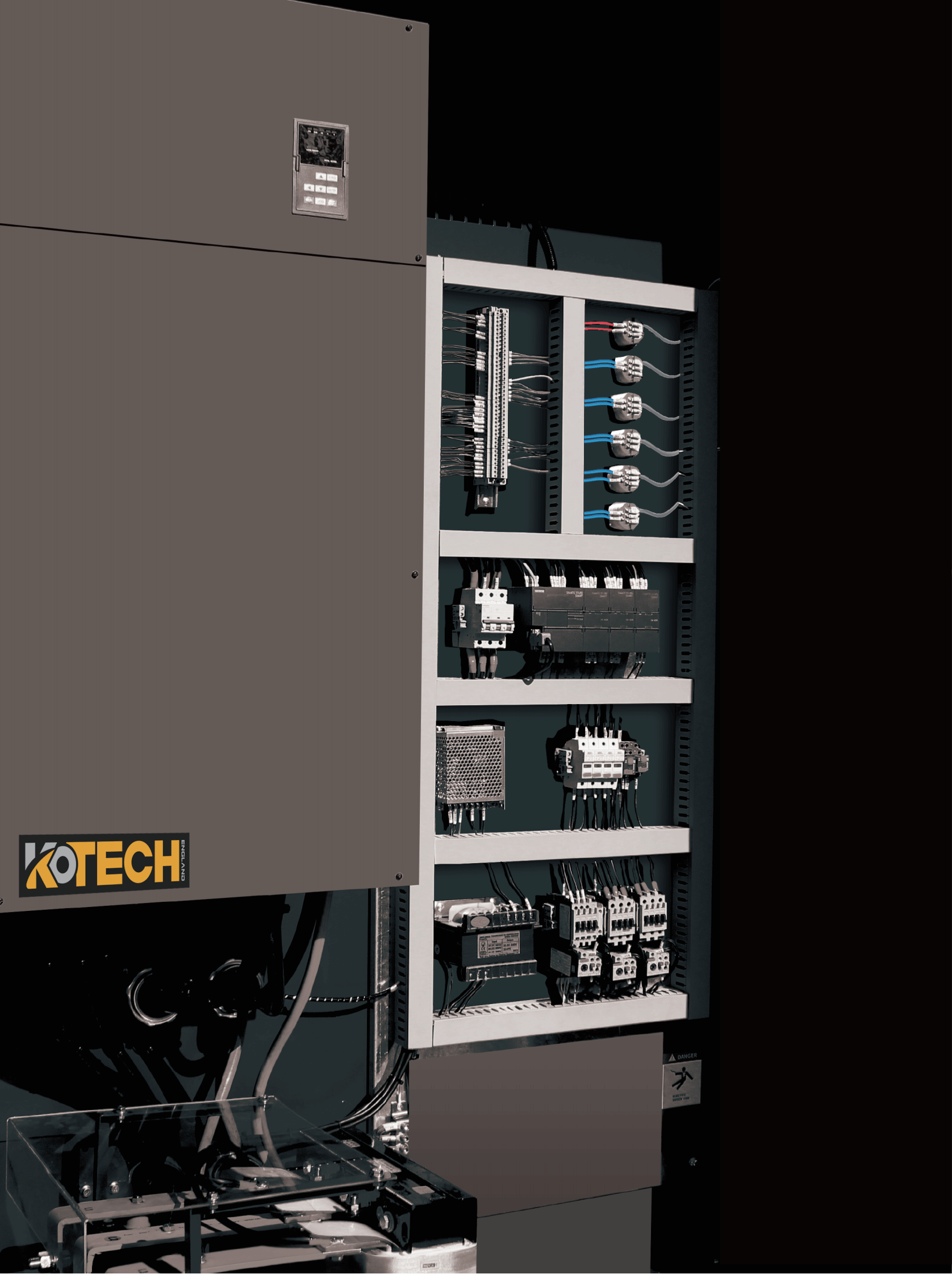

Separate KOTECH Control Cabinet

The frequency controlled variable speed drive is installed in its own control cabinet to prevent the compressor from generating heat. A separate fan maintains the operating temperature in the optimum range to ensure maximum performance and service life of the compressor.

Low Energy Consumption and High Efficiency Operation Mode

KOE’s control cabinets and machine control systems, both as individual components and as complete systems, have been tested and certified. KOE’s control cabinets and control systems, both as individual components and as complete systems, have been tested and certified to achieve high efficiency, low energy consumption and high efficiency operation mode at very low operating costs through intelligent power distribution control. Low energy consumption and high efficiency operation mode is accomplished through intelligent power distribution control with very low operating costs.

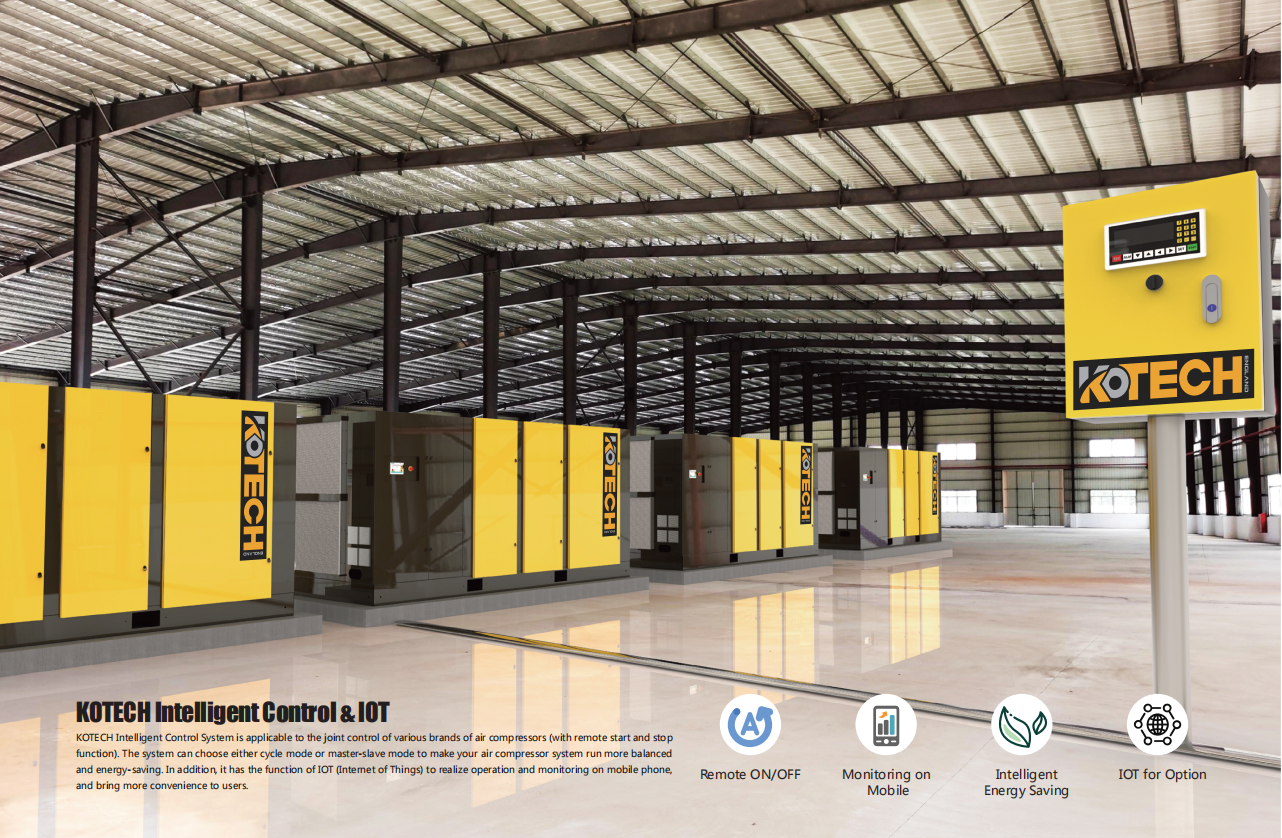

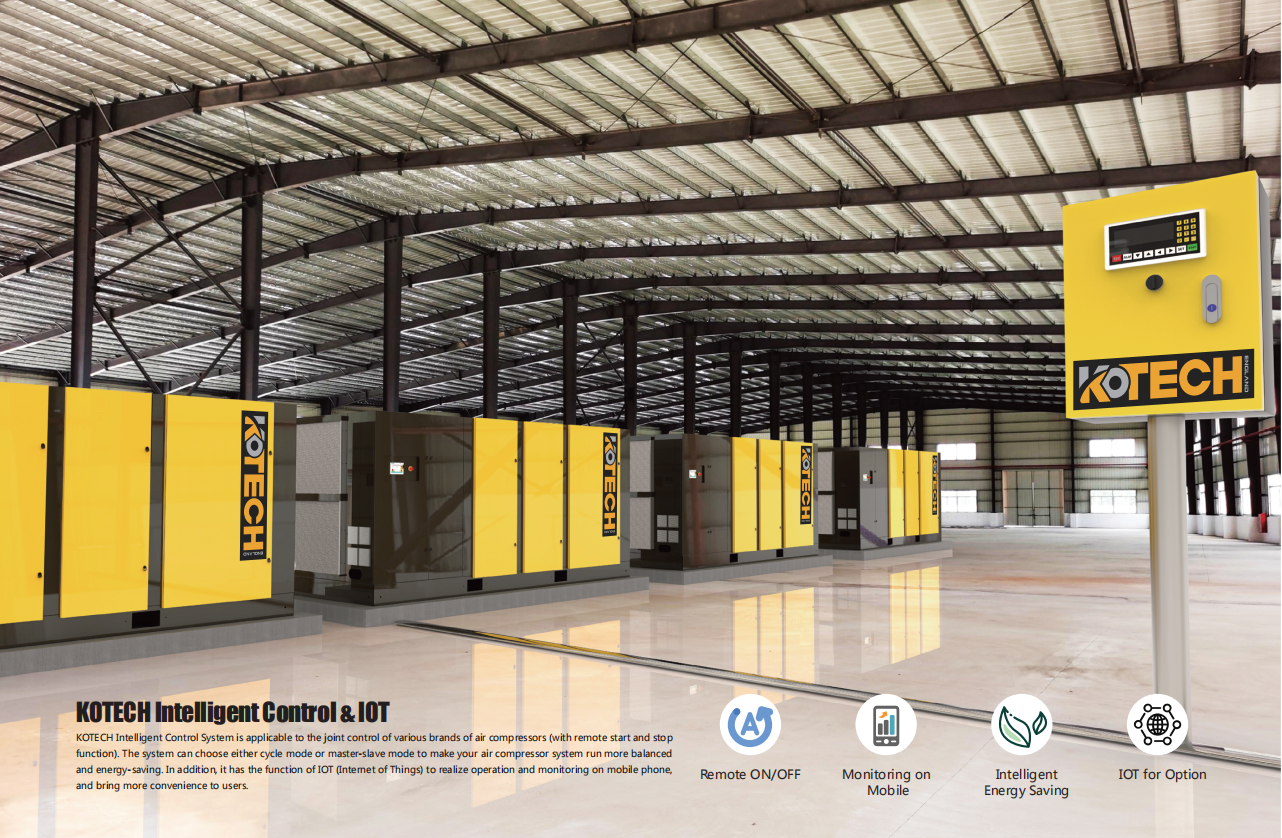

KOE Series Leading Intelligent Control System

Data Monitoring

IoT data acquisition gateway, based on the user’s different use scenarios, there are two kinds of access programs: external and embedded.

- Cloud configuration protocol: support MODBUS-RTU, CAN protocol, DLT 645-2007, MODBUS-TCP, S7, PROFINET and other communication protocols.

- Supports remote start stop, data collection, parameter modification, remote program upgrading, etc.

- Adopts electrical isolation and communication isolation technology, with strong anti-interference ability and stable signal transmission.

- Single device supports 220V and 24V voltage at the same time, without external power supply.

- Support 2G, 4G, LORA, NB-IOT, Ethernet and other communication modes.

Get Ultimate Guide

Our Support

Our Support

Solution

The solutions mainly include: automatic sensing test, automatic data acquisition and transmission, data processing and control, and data output visualization. In the automatic sensing test part, namely the sensor part, its basic function is to detect signals and signal conversion. The sensor is at the front end of the system and is used to obtain monitoring signals. Its performance will directly affect the whole system and play a decisive role in measuring accuracy.

The industrial visualization platform can be based on the 3D real-time rendering engine through 3D virtual reality technology, combined with highly realistic image rendering, and ensure the visual presentation of visual ization objects through the built-in visualization model, effect library, and 3D simulation effects of industrial plants and equipment.

The virtual reality technology is organically integrated into the industrial monitoring system. For various data generated during the operation of the equipment, such as equipment temperature, speed, current, voltage, and various real-time capacity, statistical summary data, we give full play to the advantages of data visualization, and reasonably group the data instruments according to the needs of different post monitoring to achieve rapid state switching and adapt to different scenarios.

| Model | Air delivery(m³/min) | Outlet connection | Dimension | Noise | Weight | |||

| 7.5Bar | 8.5Bar | 10Bar | 13Bar | BSPT | mm | d(BA) | Kg | |

| KOE-2.2 | 0.43 | 0.39 | 0.34 | 0.3 | 3/4” | 750*600*650 | 61 | 156 |

| KOE-2.2VSD | 0.19 ~0.43 | 0.18 ~0.39 | 0.15 ~0.34 | 0.14 ~0.3 | 3/4” | 750*600*650 | 61 | 156 |

| KOE-4 | 0.59 | 0.56 | 0.44 | 0.34 | 3/4” | 750*600*650 | 61 | 156 |

| KOE-4VSD | 0.27 ~0.59 | 0.25 ~0.56 | 0.20 ~0.44 | 0.15 ~0.34 | 3/4” | 750*600*650 | 61 | 156 |

| KOE-7.5 | 1.2 | 1 | 0.9 | 0.82 | 3/4” | 855*550*807 | 61 | 156 |

| KOE-7.5VSD | 0.54 ~1.2 | 0.45 ~1 | 0.41 ~0.9 | 0.37 ~0.82 | 3/4” | 855*550*807 | 61 | 254 |

| KOE-11 | 1.82 | 1.7 | 1.52 | 1.35 | 1” | 1014*690*1190 | 63 | 317 |

| KOE-11VSD | 0.82 ~1.82 | 0.77 ~1.7 | 0.68 ~1.52 | 0.61 ~1.35 | 1” | 1014*690*1190 | 63 | 322 |

| KOE-15 | 2.5 | 2.3 | 2.1 | 1.8 | 1” | 1014*690*1190 | 63 | 350 |

| KOE-15VSD | 1.13 ~2.5 | 1.04 ~2.3 | 0.95 ~2.1 | 0.81 ~1.8 | 1” | 1014*690*1190 | 63 | 355 |

| KOE-18 | 3.2 | 3 | 2.7 | 2.4 | 1-1/4” | 1250*773*1200 | 63 | 453 |

| KOE-22 | 3.9 | 3.7 | 3.2 | 2.8 | 1-1/4” | 1250*773*1200 | 63 | 480 |

| KOE-18VSD | 1.44 ~3.2 | 1.35 ~3 | 1.22 ~2.7 | 1.08 ~2.4 | 1-1/4” | 1000*800*1330 | 63 | 458 |

| KOE-22VSD | 1.76 ~3.9 | 1.67 ~3.7 | 1.44 ~3.2 | 1.26 ~2.8 | 1-1/4” | 1000*800*1330 | 63 | 485 |

| KOE-30 | 5.4 | 5 | 4.6 | 4 | 1-1/4” | 1450*923*1270 | 67 | 669 |

| KOE-37 | 6.6 | 6.3 | 5.6 | 4.9 | 1-1/4” | 1450*923*1270 | 67 | 669 |

| KOE-45 | 8.3 | 7.7 | 7.2 | 6.4 | 1-1/4” | 1450*923*1270 | 67 | 702 |

| Model | Air delivery(m³/min) | Outlet connection | Dimension | Noise | Weight | |||

| 7.5Bar | 8.5Bar | 10Bar | 13Bar | BSPT | mm | d(BA) | Kg | |

| KOE-30VSD | 2.43 ~5.4 | 2.25 ~5 | 2.07 ~4.6 | 1.80 ~4 | 1-1/4” | 843*944*1521 | 67 | 674 |

| KOE-37VSD | 3.06 ~6.8 | 2.93 ~6.5 | 2.61 ~5.8 | 2.30 ~5.1 | 1-1/4” | 843*944*1521 | 67 | 674 |

| KOE-45VSD | 3.74 ~8.3 | 3.47 ~7.7 | 3.24 ~7.2 | 2.88 ~6.4 | 1-1/4” | 843*944*1521 | 67 | 7110 |

| Model | Air delivery(m³/min) | Outlet connection | Dimension | Noise | Weight | |||

| 7.5Bar | 8.5Bar | 10Bar | 13Bar | BSPT | mm | d(BA) | Kg | |

| KOE-55 | 10.3 | 10.1 | 8.4 | 7.6 | 2” | 1750*1200*1900 | 72 | 458 |

| KOE-75 | 14 | 12.8 | 11.8 | 10.6 | 2” | 1750*1200*1900 | 75 | 1480 |

| KOE-55VSD | 4.64 ~10.3 | 4.55 ~10.1 | 3.78 ~8.4 | 3.42 ~7.6 | 2” | 1600*1200*1900 | 72 | 1535 |

| KOE-75VSD | 6.30 ~14 | 5.76 ~12.8 | 5.31 ~11.8 | 4.77 ~10.6 | 2” | 1600*1200*1900 | 75 | 1540 |

| KOE-90 | 16.4 | 15.3 | 13.8 | 12.4 | 2” | 2050*1500*1850 | 75 | 1491 |

| KOE-110 | 21 | 20 | 19 | 15.3 | DN80 | 2050*1500*1850 | 78 | 2250 |

| KOE-90VSD | 7.38 ~16.4 | 6.89 ~15.3 | 6.21 ~13.8 | 5.58 ~12.4 | 2” | 2050*1500*1850 | 75 | 1650 |

| KOE-110VSD | 10.17 ~22.6 | 9.00 ~20 | 8.55 ~19 | 6.89 ~15.3 | DN80 | 2050*1500*1850 | 78 | 2410 |

| KOE-132 | 25.2 | 23.2 | 21 | 18.8 | DN80 | 2780*1670*1850 | 78 | 2450 |

| KOE-132VSD | 11.34 ~25.2 | 10.44 ~23.2 | 9.45 ~21 | 8.46 ~18.8 | DN80 | 2780*1670*1850 | 78 | 2610 |

| KOE-160 | 29.2 | 27.9 | 24.6 | 21.9 | DN80 | 2780*1670*1850 | 78 | 2900 |

| KOE-160VSD | 13.14 ~29.2 | 12.56 ~27.9 | 11.07 ~24.6 | 9.86 ~21.9 | DN80 | 2780*1670*1850 | 78 | 3220 |

| KOE-185 | 32.6 | 30.4 | 27.6 | 25.3 | DN80 | 2780*1670*1850 | 78 | 3480 |

| KOE-185VSD | 14.67 ~32.6 | 13.68 ~30.4 | 12.42 ~27.6 | 11.39 ~25.3 | DN80 | 2780*1670*1850 | 78 | 3720 |

| KOE-200 | 35.3 | 33.87 | 30.3 | 27.7 | DN100 | 4600*2100*2270 | 85 | 4130 |

| kOE-200VSD | 15.89 ~35.3 | 15.24 ~33.87 | 13.64 ~30.3 | 12.47 ~27.7 | DN100 | 4600*2100*2270 | 85 | 4450 |

| KOE-220 | 47.5 | 44.5 | 38.7 | 34.2 | DN125 | 4600*2100*2270 | 85 | 5020 |

| KOE-220VSD | 21.38 ~47.5 | 20.03 ~44.5 | 17.42 ~38.7 | 15.39 ~34.2 | DN125 | 600*2100*2270 | 85 | 5340 |

| KOE-250 | 50.1 | 48.1 | 43.29 | 37.5 | DN125 | 4600*2100*2270 | 85 | 5020 |

| KOE-250VSD | 22.55 ~50.1 | 21.65 ~48.1 | 19.48 ~43.29 | 16.88 ~37.5 | DN125 | 4600*2100*2270 | 85 | 5340 |

| KOE-315 | 65 | 58.1 | 52.29 | 45.2 | DN150 | 4600*2100*2400 | 85 | 7760 |

| kOE-315VSD | 29.25 ~65 | 26.15 ~58.1 | 23.53 ~52.29 | 20.34 ~45.2 | DN150 | 4600*2100*2400 | 85 | 8160 |

| KOE-355 | 68 | 64 | 57 | 51 | DN125 | 4600*2100*2400 | 88 | 10200 |

| KOE-355VSD | 30.60 ~68 | 28.80 ~64 | 25.65 ~57 | 22.95 ~51 | DN125 | 4600*2100*2400 | 88 | 10200 |

Here’s a description of the industries that the KOE Series Air Compressor is used in:

The KOE Series Air Compressor is a high-performance rotary screw air compressor designed to cater to industries that demand superior quality and reliability. This cutting-edge compressor is meticulously engineered using top-tier components from renowned brands, making it an ideal choice for discerning clients who prioritize excellence.

Industries Served:

Manufacturing:

The KOE Series Air Compressor finds its place in various manufacturing processes where consistent and reliable compressed air is essential. From automotive assembly lines to electronics manufacturing, this compressor ensures uninterrupted production cycles, contributing to the precision and efficiency of these industries.

Food and Beverage:

In the food and beverage industry, maintaining clean and contaminant-free compressed air is crucial. The KOE Series excels in providing the hygienic and oil-free compressed air necessary for food processing, packaging, and bottling operations, ensuring the highest quality standards are met.

Pharmaceuticals:

Pharmaceutical manufacturing demands adherence to strict quality and safety regulations. The KOE Series Air Compressor’s utilization of premium components ensures that the compressed air used in critical processes, such as medication formulation and sterile environments, is free from impurities and contaminants.

Electronics:

Precision is paramount in the electronics industry, where even the tiniest particles can disrupt delicate manufacturing processes. The KOE Series offers ultra-clean compressed air that safeguards sensitive electronic components during fabrication, assembly, and testing.

Automotive:

In the automotive sector, where efficiency and reliability are paramount, the KOE Series Air Compressor ensures a steady supply of compressed air for tasks ranging from pneumatic tools in auto repair shops to automated systems on assembly lines, enhancing overall productivity.

Textiles:

Textile manufacturing demands consistent and controlled airflow for various processes like spinning, weaving, and dyeing. The KOE Series caters to these requirements by delivering stable compressed air to power the machinery involved in textile production.

Energy:

Power generation and energy exploration industries often require compressed air for crucial tasks such as instrumentation, control systems, and pneumatic tools. The KOE Series provides the reliability needed for these applications, contributing to the seamless operation of energy-related processes.

Printing and Packaging:

For high-quality printing and precise packaging, a reliable source of compressed air is indispensable. The KOE Series Air Compressor ensures consistent pressure and purity, enhancing the outcomes in printing presses and packaging lines.

In essence, the KOE Series Air Compressor serves as a vital component across diverse industries, where its dedication to exceptional quality, brand-name components, and reliable performance makes it the compressor of choice for clients who demand nothing less than the best.

You May Also Like

KES Series Oil-Injected Screw Air Compressor

0.31-58m3/min

Working Pressure: 6 – 12.5bar

Learn More >>

KFU Series Oil-lnjected Screw Air Compressor

0.31 – 58m3/min

Working Pressure: 6 – 12.5bar

Learn More >>

KOE II Series 2-Stage Screw Air Compressor

9.5 – 61.9m3/min

Working Pressure: 8 – 12.5bar

Learn More >>

KOP Series Oil Free Diesel Portable Air Compressor

12 – 48m3/min

Working Pressure: 7 – 10.3bar

Learn More >>

KOE Series Screw Air Compressor

New generation design of KOTECH – more efficient partner

Power 2.2 to 355KW; Flow rate 0.2 to 70.35 m³/min; Pressure 7.5 to 13bar

KOE Energy Saving Standard

Through improved specific power, air flow optimization and further refinement of the rotor, excellent energy efficiency is achieved. Maximize energy efficiency with a high-performance IE4 drive motor.

Kotech’s 1:1 drive design eliminates the power loss associated with the original transmission and the gear or V-belt drive system. In addition, radial fans meet the efficiency requirements of the EU Directive 327/2011 for fans. But most importantly, the advanced compressor controller, through the use of a variety of specially developed control options, achieves additional energy savings and minimizes the cost of frequent downtime.

From the outside, the unique and striking design of these systems is complemented by the intelligent component layout inside for greater energy efficiency:

For example, all service and maintenance points are within reach and directly accessible from the front, which not only saves time and money, but also maximizes the availability of the compressed air system.

Intelligent Thermal Management System

The intelligent thermal management system will introduce the high-temperature circulating oil of the air compressor thermal water heater into the unit during operation, exchange it with water to heat up the water, and absorb the heat energy in the oil and gas to cool the air compressor, prevent the air compressor from skipping at high temperature, reduce the equipment failure rate, reduce maintenance, and ensure the safe supply of air compressor to industrial enterprises.

The intelligent thermal management system can help users obtain a large amount of hot water, save other heating energy, reduce enterprise operating costs, and respond to the word call for energy conservation and emission reduction, reduce carbon dioxide emissions, and reduce air pollution.

Why Choose Heat Recovery?

There is a great need to choose heat recovery, as most of the (electrical) energy input to the compressor is converted intoheat. Up to 96% of this energy can be recycled. This not only reduces primary energy consumption, but also significantly improves the company’s overall energy balance.

Energy Saving Motor

This series of motors is a new generation of energy saving products advocated and recommended by the

nternational market at present, and meet the high

altitude, harsh environment, overload requirements of

larger occasions, is the ideal supporting power KOE air

compression.

High Efficiency Controller

KOE controller integrated power frequency conversion, with arbitrary switching of working mode; Exhaust temperature detection; PID automatic adjustment of load rate control pressure balance and other functions; Main motor lack of phase, imbalance, overload, protection function; Phase sequence detection to prevent reversal; Temperature protection: When the actual temperature is detected greater than the set shutdown temperature, the air compressor stops; Machine maintenance information Settings, reminders, perfect fault protection; According to the setting, it can communicate with the upper computer and run in conjunction with other air compressors.

Excellent Cooling Effect

The most troublesome fault for the user of the air compressor is high temperature, and the two most direct solutions to avoid high temperature are to increase the fan power and sufficient cooler dirt coefficient.

Automatic Temperature Control Technology

A thermostatically controlled fan with a variable speed motor generates the precise amount of cooling air required by the fluid cooler to ensure a lower operating temperature.

This significantly reduces the overall energy requirements of the KOE screw compressor system.

Cold Compressed Air

Effective aftercooling helps keep compressor discharge temperatures low. This combined with a centrifugal separator, removes large amounts of condensate and then drains it through an electrically controlled condensate drain without energy loss and also reduces the burden on downstream treatment equipment.

Clean Cooler from Outside

Unlike internally installed heat exchangers, externally installed coolers in KOE systems are easily accessible and easy to clean. As a result, operational reliability and availability are improved due to the ease with which contaminants can be prevented from accumulating.

High Residual Thrust for Exhaust

Integrated radial fans are much more efficient than axial fans and provide higher residual thrust. This allows the hot exhaust to be delivered directly through the pipe without the need for an auxiliary fan.

Kotech new generation of intelligent controllers , with their intuitive high-resolution, oversized color screens, are equipped with network connectivity to achieve higher levels of communication, connectivity and control, greatly enhancing the actual productivity of the air compressor.

Separate KOTECH Control Cabinet

The frequency controlled variable speed drive is installed in its own control cabinet to prevent the compressor from generating heat. A separate fan maintains the operating temperature in the optimum range to ensure maximum performance and service life of the compressor.

Low Energy Consumption and High Efficiency Operation Mode

KOE’s control cabinets and machine control systems, both as individual components and as complete systems, have been tested and certified. KOE’s control cabinets and control systems, both as individual components and as complete systems, have been tested and certified to achieve high efficiency, low energy consumption and high efficiency operation mode at very low operating costs through intelligent power distribution control. Low energy consumption and high efficiency operation mode is accomplished through intelligent power distribution control with very low operating costs.

KOE Series Leading Intelligent Control System

Data Monitoring

IoT data acquisition gateway, based on the user’s different use scenarios, there are two kinds of access programs: external and embedded.

- Cloud configuration protocol: support MODBUS-RTU, CAN protocol, DLT 645-2007, MODBUS-TCP, S7, PROFINET and other communication protocols.

- Supports remote start stop, data collection, parameter modification, remote program upgrading, etc.

- Adopts electrical isolation and communication isolation technology, with strong anti-interference ability and stable signal transmission.

- Single device supports 220V and 24V voltage at the same time, without external power supply.

- Support 2G, 4G, LORA, NB-IOT, Ethernet and other communication modes.

Get Ultimate Guide

Our Support

Our Support

Solution

The solutions mainly include: automatic sensing test, automatic data acquisition and transmission, data processing and control, and data output visualization. In the automatic sensing test part, namely the sensor part, its basic function is to detect signals and signal conversion. The sensor is at the front end of the system and is used to obtain monitoring signals. Its performance will directly affect the whole system and play a decisive role in measuring accuracy.

The industrial visualization platform can be based on the 3D real-time rendering engine through 3D virtual reality technology, combined with highly realistic image rendering, and ensure the visual presentation of visual ization objects through the built-in visualization model, effect library, and 3D simulation effects of industrial plants and equipment.

The virtual reality technology is organically integrated into the industrial monitoring system. For various data generated during the operation of the equipment, such as equipment temperature, speed, current, voltage, and various real-time capacity, statistical summary data, we give full play to the advantages of data visualization, and reasonably group the data instruments according to the needs of different post monitoring to achieve rapid state switching and adapt to different scenarios.

| Model | Air delivery(m³/min) | Outlet connection | Dimension | Noise | Weight | |||

| 7.5Bar | 8.5Bar | 10Bar | 13Bar | BSPT | mm | d(BA) | Kg | |

| KOE-2.2 | 0.43 | 0.39 | 0.34 | 0.3 | 3/4” | 750*600*650 | 61 | 156 |

| KOE-2.2VSD | 0.19 ~0.43 | 0.18 ~0.39 | 0.15 ~0.34 | 0.14 ~0.3 | 3/4” | 750*600*650 | 61 | 156 |

| KOE-4 | 0.59 | 0.56 | 0.44 | 0.34 | 3/4” | 750*600*650 | 61 | 156 |

| KOE-4VSD | 0.27 ~0.59 | 0.25 ~0.56 | 0.20 ~0.44 | 0.15 ~0.34 | 3/4” | 750*600*650 | 61 | 156 |

| KOE-7.5 | 1.2 | 1 | 0.9 | 0.82 | 3/4” | 855*550*807 | 61 | 156 |

| KOE-7.5VSD | 0.54 ~1.2 | 0.45 ~1 | 0.41 ~0.9 | 0.37 ~0.82 | 3/4” | 855*550*807 | 61 | 254 |

| KOE-11 | 1.82 | 1.7 | 1.52 | 1.35 | 1” | 1014*690*1190 | 63 | 317 |

| KOE-11VSD | 0.82 ~1.82 | 0.77 ~1.7 | 0.68 ~1.52 | 0.61 ~1.35 | 1” | 1014*690*1190 | 63 | 322 |

| KOE-15 | 2.5 | 2.3 | 2.1 | 1.8 | 1” | 1014*690*1190 | 63 | 350 |

| KOE-15VSD | 1.13 ~2.5 | 1.04 ~2.3 | 0.95 ~2.1 | 0.81 ~1.8 | 1” | 1014*690*1190 | 63 | 355 |

| KOE-18 | 3.2 | 3 | 2.7 | 2.4 | 1-1/4” | 1250*773*1200 | 63 | 453 |

| KOE-22 | 3.9 | 3.7 | 3.2 | 2.8 | 1-1/4” | 1250*773*1200 | 63 | 480 |

| KOE-18VSD | 1.44 ~3.2 | 1.35 ~3 | 1.22 ~2.7 | 1.08 ~2.4 | 1-1/4” | 1000*800*1330 | 63 | 458 |

| KOE-22VSD | 1.76 ~3.9 | 1.67 ~3.7 | 1.44 ~3.2 | 1.26 ~2.8 | 1-1/4” | 1000*800*1330 | 63 | 485 |

| KOE-30 | 5.4 | 5 | 4.6 | 4 | 1-1/4” | 1450*923*1270 | 67 | 669 |

| KOE-37 | 6.6 | 6.3 | 5.6 | 4.9 | 1-1/4” | 1450*923*1270 | 67 | 669 |

| KOE-45 | 8.3 | 7.7 | 7.2 | 6.4 | 1-1/4” | 1450*923*1270 | 67 | 702 |

| Model | Air delivery(m³/min) | Outlet connection | Dimension | Noise | Weight | |||

| 7.5Bar | 8.5Bar | 10Bar | 13Bar | BSPT | mm | d(BA) | Kg | |

| KOE-30VSD | 2.43 ~5.4 | 2.25 ~5 | 2.07 ~4.6 | 1.80 ~4 | 1-1/4” | 843*944*1521 | 67 | 674 |

| KOE-37VSD | 3.06 ~6.8 | 2.93 ~6.5 | 2.61 ~5.8 | 2.30 ~5.1 | 1-1/4” | 843*944*1521 | 67 | 674 |

| KOE-45VSD | 3.74 ~8.3 | 3.47 ~7.7 | 3.24 ~7.2 | 2.88 ~6.4 | 1-1/4” | 843*944*1521 | 67 | 7110 |

| Model | Air delivery(m³/min) | Outlet connection | Dimension | Noise | Weight | |||

| 7.5Bar | 8.5Bar | 10Bar | 13Bar | BSPT | mm | d(BA) | Kg | |

| KOE-55 | 10.3 | 10.1 | 8.4 | 7.6 | 2” | 1750*1200*1900 | 72 | 458 |

| KOE-75 | 14 | 12.8 | 11.8 | 10.6 | 2” | 1750*1200*1900 | 75 | 1480 |

| KOE-55VSD | 4.64 ~10.3 | 4.55 ~10.1 | 3.78 ~8.4 | 3.42 ~7.6 | 2” | 1600*1200*1900 | 72 | 1535 |

| KOE-75VSD | 6.30 ~14 | 5.76 ~12.8 | 5.31 ~11.8 | 4.77 ~10.6 | 2” | 1600*1200*1900 | 75 | 1540 |

| KOE-90 | 16.4 | 15.3 | 13.8 | 12.4 | 2” | 2050*1500*1850 | 75 | 1491 |

| KOE-110 | 21 | 20 | 19 | 15.3 | DN80 | 2050*1500*1850 | 78 | 2250 |

| KOE-90VSD | 7.38 ~16.4 | 6.89 ~15.3 | 6.21 ~13.8 | 5.58 ~12.4 | 2” | 2050*1500*1850 | 75 | 1650 |

| KOE-110VSD | 10.17 ~22.6 | 9.00 ~20 | 8.55 ~19 | 6.89 ~15.3 | DN80 | 2050*1500*1850 | 78 | 2410 |

| KOE-132 | 25.2 | 23.2 | 21 | 18.8 | DN80 | 2780*1670*1850 | 78 | 2450 |

| KOE-132VSD | 11.34 ~25.2 | 10.44 ~23.2 | 9.45 ~21 | 8.46 ~18.8 | DN80 | 2780*1670*1850 | 78 | 2610 |

| KOE-160 | 29.2 | 27.9 | 24.6 | 21.9 | DN80 | 2780*1670*1850 | 78 | 2900 |

| KOE-160VSD | 13.14 ~29.2 | 12.56 ~27.9 | 11.07 ~24.6 | 9.86 ~21.9 | DN80 | 2780*1670*1850 | 78 | 3220 |

| KOE-185 | 32.6 | 30.4 | 27.6 | 25.3 | DN80 | 2780*1670*1850 | 78 | 3480 |

| KOE-185VSD | 14.67 ~32.6 | 13.68 ~30.4 | 12.42 ~27.6 | 11.39 ~25.3 | DN80 | 2780*1670*1850 | 78 | 3720 |

| KOE-200 | 35.3 | 33.87 | 30.3 | 27.7 | DN100 | 4600*2100*2270 | 85 | 4130 |

| kOE-200VSD | 15.89 ~35.3 | 15.24 ~33.87 | 13.64 ~30.3 | 12.47 ~27.7 | DN100 | 4600*2100*2270 | 85 | 4450 |

| KOE-220 | 47.5 | 44.5 | 38.7 | 34.2 | DN125 | 4600*2100*2270 | 85 | 5020 |

| KOE-220VSD | 21.38 ~47.5 | 20.03 ~44.5 | 17.42 ~38.7 | 15.39 ~34.2 | DN125 | 600*2100*2270 | 85 | 5340 |

| KOE-250 | 50.1 | 48.1 | 43.29 | 37.5 | DN125 | 4600*2100*2270 | 85 | 5020 |

| KOE-250VSD | 22.55 ~50.1 | 21.65 ~48.1 | 19.48 ~43.29 | 16.88 ~37.5 | DN125 | 4600*2100*2270 | 85 | 5340 |

| KOE-315 | 65 | 58.1 | 52.29 | 45.2 | DN150 | 4600*2100*2400 | 85 | 7760 |

| kOE-315VSD | 29.25 ~65 | 26.15 ~58.1 | 23.53 ~52.29 | 20.34 ~45.2 | DN150 | 4600*2100*2400 | 85 | 8160 |

| KOE-355 | 68 | 64 | 57 | 51 | DN125 | 4600*2100*2400 | 88 | 10200 |

| KOE-355VSD | 30.60 ~68 | 28.80 ~64 | 25.65 ~57 | 22.95 ~51 | DN125 | 4600*2100*2400 | 88 | 10200 |

Here’s a description of the industries that the KOE Series Air Compressor is used in:

The KOE Series Air Compressor is a high-performance rotary screw air compressor designed to cater to industries that demand superior quality and reliability. This cutting-edge compressor is meticulously engineered using top-tier components from renowned brands, making it an ideal choice for discerning clients who prioritize excellence.

Industries Served:

Manufacturing:

The KOE Series Air Compressor finds its place in various manufacturing processes where consistent and reliable compressed air is essential. From automotive assembly lines to electronics manufacturing, this compressor ensures uninterrupted production cycles, contributing to the precision and efficiency of these industries.

Food and Beverage:

In the food and beverage industry, maintaining clean and contaminant-free compressed air is crucial. The KOE Series excels in providing the hygienic and oil-free compressed air necessary for food processing, packaging, and bottling operations, ensuring the highest quality standards are met.

Pharmaceuticals:

Pharmaceutical manufacturing demands adherence to strict quality and safety regulations. The KOE Series Air Compressor’s utilization of premium components ensures that the compressed air used in critical processes, such as medication formulation and sterile environments, is free from impurities and contaminants.

Electronics:

Precision is paramount in the electronics industry, where even the tiniest particles can disrupt delicate manufacturing processes. The KOE Series offers ultra-clean compressed air that safeguards sensitive electronic components during fabrication, assembly, and testing.

Automotive:

In the automotive sector, where efficiency and reliability are paramount, the KOE Series Air Compressor ensures a steady supply of compressed air for tasks ranging from pneumatic tools in auto repair shops to automated systems on assembly lines, enhancing overall productivity.

Textiles:

Textile manufacturing demands consistent and controlled airflow for various processes like spinning, weaving, and dyeing. The KOE Series caters to these requirements by delivering stable compressed air to power the machinery involved in textile production.

Energy:

Power generation and energy exploration industries often require compressed air for crucial tasks such as instrumentation, control systems, and pneumatic tools. The KOE Series provides the reliability needed for these applications, contributing to the seamless operation of energy-related processes.

Printing and Packaging:

For high-quality printing and precise packaging, a reliable source of compressed air is indispensable. The KOE Series Air Compressor ensures consistent pressure and purity, enhancing the outcomes in printing presses and packaging lines.

In essence, the KOE Series Air Compressor serves as a vital component across diverse industries, where its dedication to exceptional quality, brand-name components, and reliable performance makes it the compressor of choice for clients who demand nothing less than the best.

You May Also Like

KES Series Oil-Injected Screw Air Compressor

0.31-58m3/min

Working Pressure: 6 – 12.5bar

Learn More >>

KFU Series Oil-lnjected Screw Air Compressor

0.31 – 58m3/min

Working Pressure: 6 – 12.5bar

Learn More >>

KOE II Series 2-Stage Screw Air Compressor

9.5 – 61.9m3/min

Working Pressure: 8 – 12.5bar

Learn More >>

KOP Series Oil Free Diesel Portable Air Compressor

12 – 48m3/min

Working Pressure: 7 – 10.3bar

Learn More >>