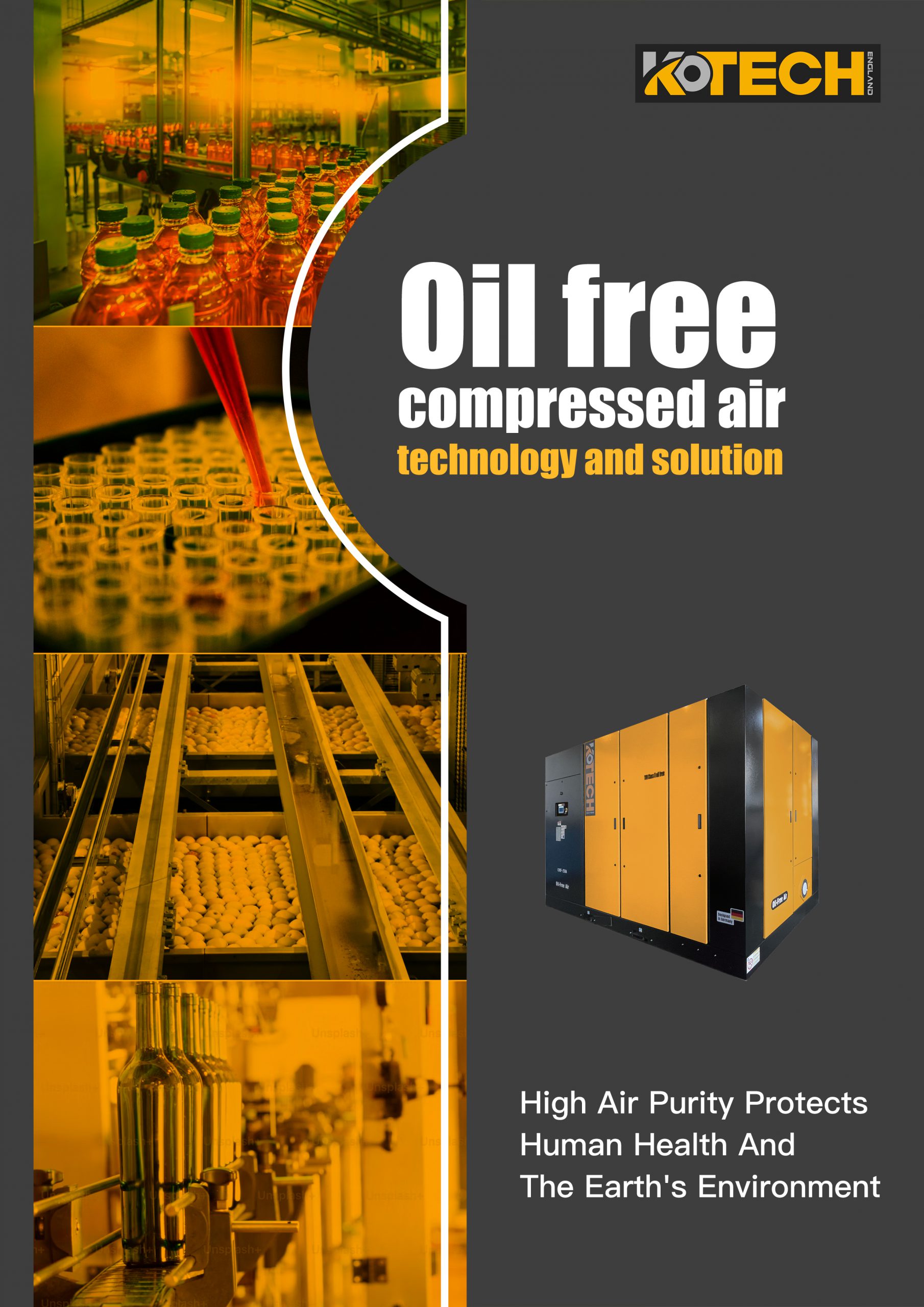

Applications of Air Compressors in Food & Beverage.

(Food & Beverage packaging will become a new growth point for the automated packaging machinery industry.)

Food and Beverage Industry

The food and beverage industry is one of the most important and rapidly growing industries, and it is essential to use the best quality equipment and machinery to ensure food and beverage products of the highest quality. According to the World Bank, the food and beverage industry is estimated to be worth $4.8 trillion globally and is expected to grow by 7.2% every year by 2021.

Compressed air is commonly used in the food and beverage industry to ensure safe, efficient and reliable operations. However, contamination from compressed air can be a major source of concern for the industry.

Therefore, it is important to use the best quality equipment and machinery to ensure that the food and beverage products are of the highest quality.

Importance of Food Safety

Food safety is an important component of food security that is often overlooked. Yet, approximately 600 million people globally fall ill after consuming food contaminated by bacteria, viruses, parasites, or chemical substances, and 420, 000 die every year. Fresh foods are responsible for a significant number of illnesses. In Kenya, for example, contamination of meat, fruits, and vegetables is relatively common.

There have been reports of kale contamination with fecal bacteria attributed to unsafe water for cleaning produce and meat contamination caused by poor hygiene practices, extensive manual handling of meat, limited worker skills, poor infrastructure, and inadequate supply of safe water. Other factors associated with food contamination include lack of structures to display food, planting foods in unsafe water, and food preparation in unhygienic environments.[Source: aphrc.org]

When it comes to guaranteeing a secure air compressor system, partnering with Kotech Compressor is the best way to find the ideal air compressor for food and beverage industries.

“This situation is not unique in the slum where you find food being sold near a sewer that has burst. The sewage [pipes] here are always bursting and the vendors continue selling their food near them without knowing that it contaminates the food they are selling” – Resident, Mukuru slum.

ANTONINA NAMAEMBA MUTORO

Postdoctoral Research Scientist

Air Compressor Applications Inside the Food and Beverage Industry

There are a wide variety of ways that air compressors can be employed within the food and beverage sector, such as:

- Packaging

- Filling

- Mixing

- Air knives

- Fluid pumping.

The type of air compressor that would suit your enterprise best will be contingent on the purpose for which it is needed, in addition to the size of your company.

Kotech Compressor suggests the following products

Air compressors for food and beverage applications are:

Are you looking for a reliable and efficient power source for your textile industry? Kotech dealers are experienced in finding the perfect air compressor for your needs.

Contact your local Kotech dealer today and discover how an air compressor can increase your productivity and safety.

How to Choose the Right Air Compressor for Sandblasting

The food and beverage industry is one of the most important industries in the world and air compressors are an important part of the food and beverage industry, used for a variety of different tasks. From packaging to processing, filling to labelling, capping to vacuum packaging, air compressors are essential for efficient and reliable operations.

Kotech Products in Action

For food and beverage applications, the best air compressors are oil-lubricated and oil-free models. Both types can be safely and effectively used and filtered to provide high-quality compressed air with minimal contamination.

Kotech Compressor recommends reciprocating and rotary screw compressors for food and beverage plant use due to their consistent performance, ease-of-use, and low maintenance costs.

- Rotary screw models are the most common for beverage plant use and offer a large volume of air in a small space.

- Reciprocating air compressors are more suitable for larger settings, heavy-duty deployments, and continuous-use situations.

They also work well with existing piping. When selecting an air compressor for food and beverage applications, consider your total air compression needs, consistency over time, and how many people will be using the system at once.