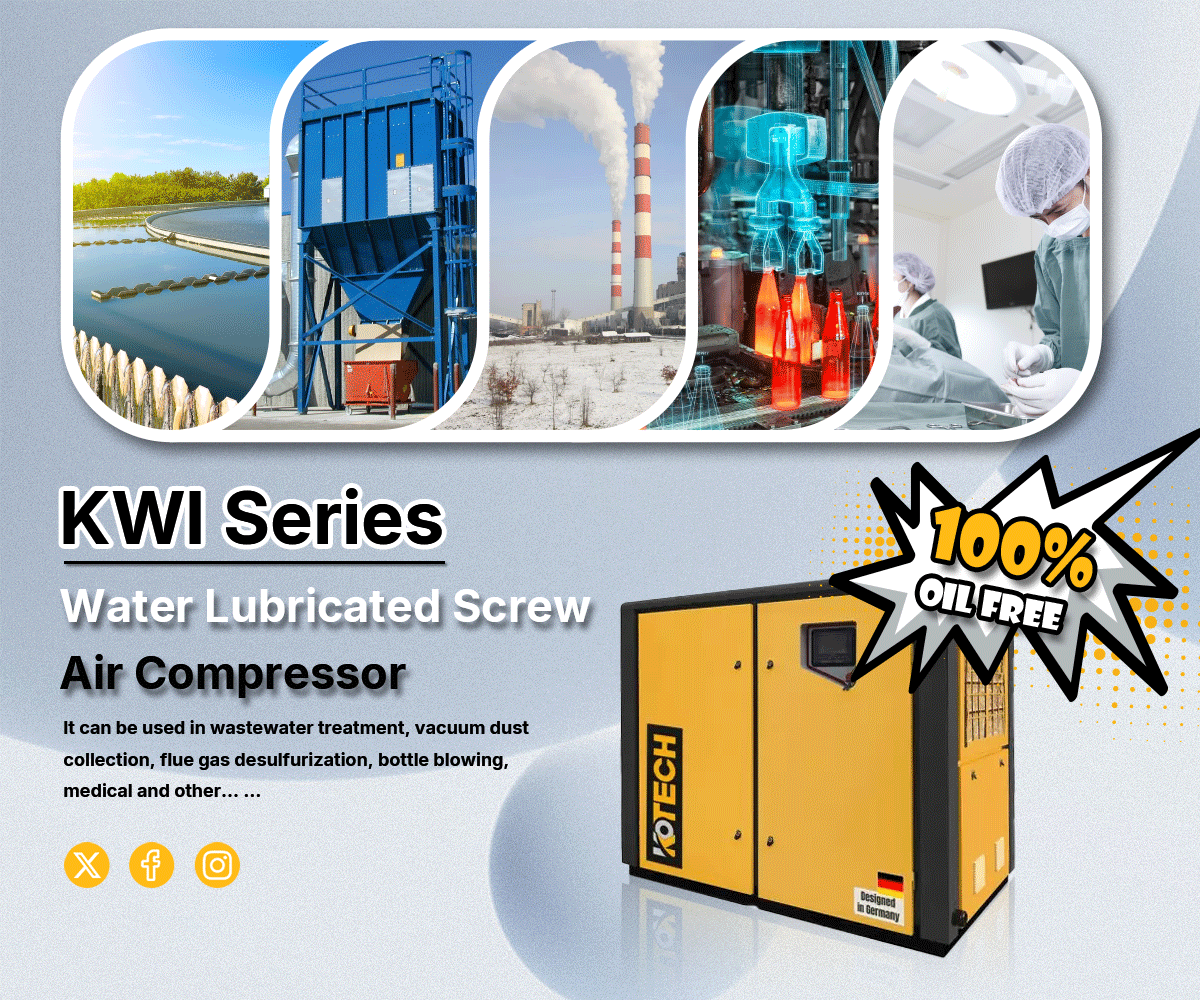

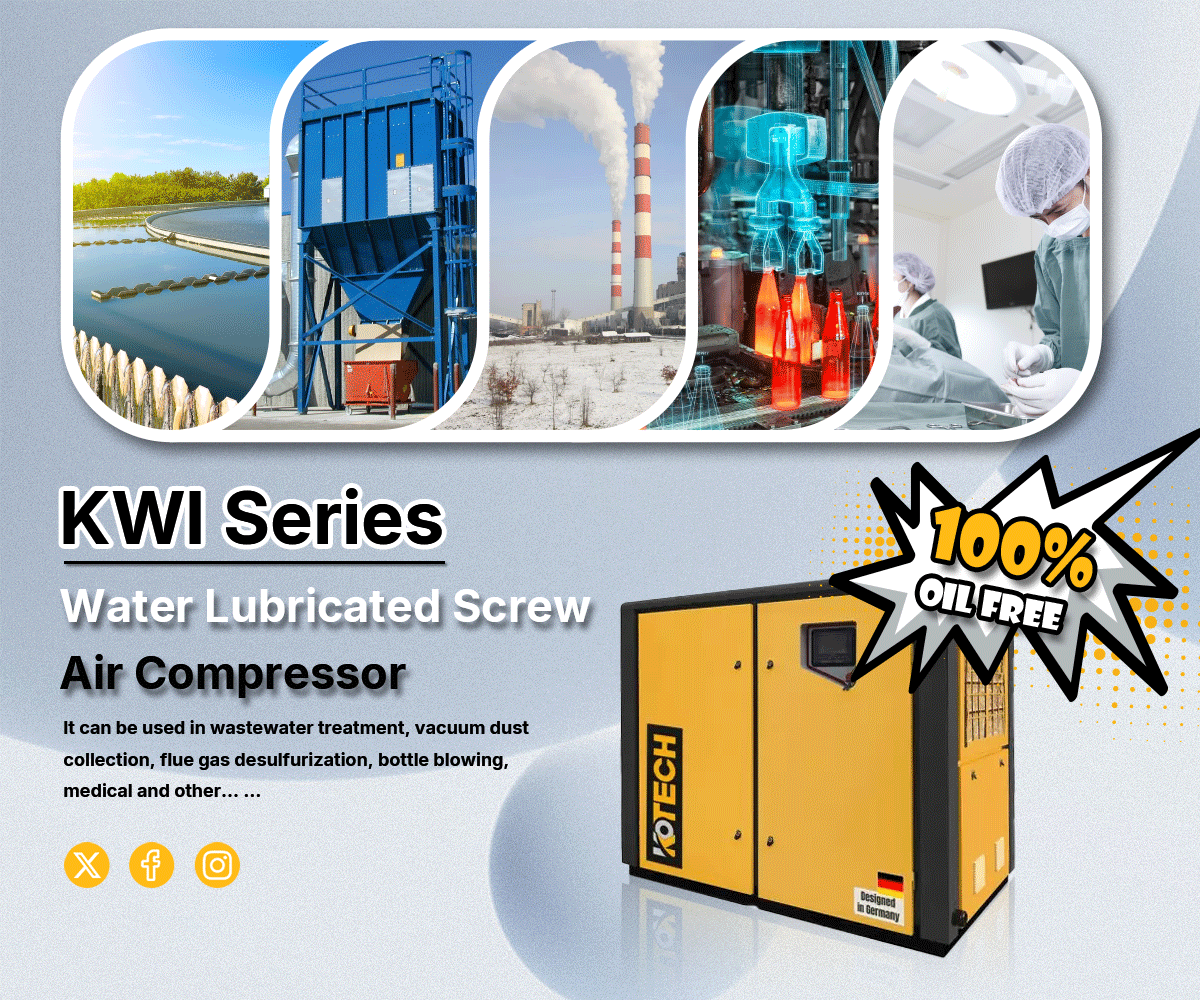

KWI Series

100% Oil Free Water Lubricated Screw Air Compressor

Variable Frequency Oil Free Water Lubricated Compressor: Air cooling 15kw to 500kw Water cooling 37kw to 500kw

Best Efficiency of Inverter

Completely free from the problem of oil

Oil free type with maximum flow rate

Lowest management & repair cost

Highest efficiency and energy saving

Sealing, lubrication, and chilling with pure water (completely oil free)

Social Sharing:

The undisputed leader of prevent global warming, Energy conservation, and environment protection

The power consumption of air compressor is occupied about 5% among a regional total power consumption. In Particular, due to the power consumption of the compressor takes up 20% ~ 30% of the total power consumption in a plant, cuts down the power consumption of the compressor is the most effective energy saving way.

High-efficiency energy-saving single screw compressor is contributing to prevent of global warming by reducing CO2. In addition, due to using no oil, not only the best way to resolve environment and energy conservation but also ISO14000 measures in water pollution and waste management and HACCP hygiene operations. Moreover, it is very safety from heat ignition due to relatively low compression temperature at about 40℃.

Single-Screw —- Ideal compression mechanism

A simple construction and water-seal effect deliver ideal operating efficiency.

The “Single-Screw” pump’s construction use a single screw rotor and two gate rotors, one placed on either side of the screw rotor.

This is simple construction transmits pressure to the rotating axle with good balance, and prevents excessive load on the bearings this is one of the reasons for the “Single-Screw” pump’s high efficiency. The water used as a lubricating medium also seals gaps inside the compression chamber.

Compressed air is thus kept from leaking, enabling the “Single-Screw” pump to generate sufficient discharge even at low rotating speeds. This reduces both noise and vibration. The cooling effect of the water lubricant also prevent heating from the compression process (the discharge air temperature is about 40℃.), making the compression process more efficient and eliminating the need for a cooling apparatus.

This improves both safety and durability significantly. The fusion of our unique compression mechanism and new water – lubricant technology is helping greatly to improve energy in a wide range of fields.

Precision processing techniques of high reliability

The center of the rotor has characteristics of SINGLE-SCREW consumption structure that shows high efficiency and stability by utilizing super precision technology of Mitsui Seiki that is also a maker of machine tools.

| Model | KWI-7.5A | KWI-11A | KWI-15A | KWI-18.5A | KWI-22A | KWI-30A | |||||||||||||||||||

| Working Pressure | psig | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 181 |

| bar | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 12.5 | |

| Air Delivery | cfm | 38.8 | 35.3 | 30.0 | 24.7 | 63.6 | 58.3 | 53.0 | 45.9 | 84.7 | 77.7 | 74.2 | 63.6 | 109.5 | 102.4 | 95.3 | 81.2 | 134.2 | 127.1 | 113.0 | 88.3 | 187.1 | 176.6 | 151.8 | 127.1 |

| m3/min | 1.1 | 1 | 0.85 | 0.7 | 1.8 | 1.65 | 1.5 | 1.3 | 2.4 | 2.2 | 2.1 | 1.8 | 3.1 | 2.9 | 2.7 | 2.3 | 3.8 | 3.6 | 3.2 | 2.5 | 5.3 | 5 | 4.3 | 3.6 | |

| Motor Power | kw/hp | 7.5/10 | 11/15 | 15/20 | 18.5/25 | 22/30 | 30/40 | ||||||||||||||||||

| Type of Cooling | Air Cooling / Water Cooling | ||||||||||||||||||||||||

| Motor Power (L*W*H)(mm) | 1300*800*1300 | 1300*800*1300 | 1620*1004*1410 | 1600*910*1350 | 1450*1000*1560 | 1950*1050*1432 | |||||||||||||||||||

| Weight(kg) | 500 | 540 | 650 | 840 | 870 | 980 | |||||||||||||||||||

| Output pipe Diameter | 3/4″ | 1″ | 1″ | 1″ | 1″ | 11/4″ | |||||||||||||||||||

| Model | KWI-37A | KWI-45A | KWI-55A | KWI-75A | KWI-90A | KWI-110W | ||||||||||||||||

| Working Pressure | psig | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 100 | 116 | 145 | 100 | 116 | 145 |

| bar | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 7 | 8 | 10 | 7 | 8 | 10 | |

| Air Delivery | cfm | 233.0 | 218.9 | 201.3 | 162.4 | 282.5 | 271.9 | 243.6 | 211.9 | 370.8 | 346.0 | 307.2 | 257.8 | 480.2 | 459.0 | 409.6 | 572.0 | 547.3 | 494.3 | 734.4 | 688.5 | 582.6 |

| m3/min | 6.6 | 6.2 | 5.7 | 4.6 | 8 | 7.7 | 6.9 | 6 | 10.5 | 9.8 | 8.7 | 7.3 | 13.6 | 13 | 11.6 | 16.2 | 15.5 | 14 | 20.8 | 19.5 | 16.5 | |

| Motor Power | kw/hp | 37/50 | 45/60 | 55/75 | 75/100 | 90/120 | 110/150 | |||||||||||||||

| Type of Cooling | Air Cooling / Water Cooling | |||||||||||||||||||||

| Motor Power (L*W*H)(mm) | 1700*1100*1630 | 2150*1300*1590 | 2200*1400*1540 | 2400*1450*1740 | 2550*1400*1605 | 2700*1550*1750 | ||||||||||||||||

| Weight(kg) | 1000 | 1060 | 1250 | 1480 | 2030 | 2450 | ||||||||||||||||

| Output pipe Diameter | 11/4″ | 11/2″ | 2″ | 2″ | DN50 | DN65 | ||||||||||||||||

| Model | KWI-132W | KWI-160W | KWI-200W | KWI-250W | KWI-280W | KWI-315W | KWI-400W | |||||||||||||||

| Working Pressure | psig | 100 | 116 | 145 | 100 | 116 | 145 | 100 | 116 | 145 | 100 | 116 | 145 | 100 | 116 | 145 | 100 | 116 | 145 | 100 | 116 | 145 |

| bar | 7 | 8 | 10 | 7 | 8 | 10 | 7 | 8 | 10 | 7 | 8 | 10 | 7 | 8 | 10 | 7 | 8 | 10 | 7 | 8 | 10 | |

| Air Delivery | cfm | 847.7 | 812.1 | 706.2 | 981.6 | 935.7 | 829.8 | 1218.2 | 1165.2 | 988.7 | 1518.3 | 1412.4 | 1306.5 | 1800.8 | 1765.5 | 1589.0 | 1977.4 | 1942.1 | 1730.2 | 2259.8 | 2471.7 | 2153.9 |

| m3/min | 24 | 23 | 20 | 27.8 | 26.5 | 23.5 | 34.5 | 33 | 28 | 43 | 40 | 37 | 51 | 50 | 45 | 56 | 55 | 49 | 64 | 70 | 61 | |

| Motor Power | kw/hp | 132/175 | 160/200 | 200/270 | 250/330 | 280/375 | 315/420 | 400/550 | ||||||||||||||

| Type of Cooling | Air Cooling / Water Cooling | |||||||||||||||||||||

| Motor Power (L*W*H)(mm) | 2600*1650*1750 | 3300*2200*2000 | 3300*2200*2200 | 3670*2070*2370 | 4000*2000*2100 | 4600*2300*2400 | 4600*2300*2400 | |||||||||||||||

| Weight(kg) | 2850 | 3750 | 4100 | 4750 | ||||||||||||||||||

| Output pipe Diameter | DN65 | DN65 | DN80 | DN125 | DN150 | DN125 | DN150 | |||||||||||||||

| Model | KWI-450W | KWI-500W | |||||

| Working Pressure | psig | 100 | 116 | 145 | 100 | 116 | 145 |

| bar | 7 | 8 | 10 | 7 | 8 | 10 | |

| Air Delivery | cfm | 2860.1 | 2789.5 | 2471.7 | 3142.6 | 3072.0 | 2718.9 |

| m3/min | 81 | 79 | 70 | 89 | 87 | 77 | |

| Motor Power | kw/hp | 450/600 | 500/670 | ||||

| Type of Cooling | Air Cooling / Water Cooling | ||||||

| Motor Power (L*W*H)(mm) | 5500*2590*2800 | 5500*2590*2800 | |||||

| Weight(kg) | |||||||

| Output pipe Diameter | DN175 | DN200 | |||||

You May Also Like

KOP Series Oil Free Diesel Portable Air Compressor;

12 – 48m3/min

Working Pressure: 7 – 10.3bar

Learn More >>

KUW Series Silent Oil Free Scroll Air Compressor

140 – 4100L/min

Working Pressure: 7 – 10bar

Learn More >>

KDOF Series Oil Free Dry Screw Air Compressor

7.98 – 58.44m3/min

Working Pressure: 11bar

Learn More >>

KSB Series

Low Pressure Oil Free Air Blower

1500 – 4040m3/min

Working Pressure: 0.5 – 2.5bar

Learn More >>

The undisputed leader of prevent global warming, Energy conservation, and environment protection

The power consumption of air compressor is occupied about 5% among a regional total power consumption. In Particular, due to the power consumption of the compressor takes up 20% ~ 30% of the total power consumption in a plant, cuts down the power consumption of the compressor is the most effective energy saving way.

High-efficiency energy-saving single screw compressor is contributing to prevent of global warming by reducing CO2. In addition, due to using no oil, not only the best way to resolve environment and energy conservation but also ISO14000 measures in water pollution and waste management and HACCP hygiene operations. Moreover, it is very safety from heat ignition due to relatively low compression temperature at about 40℃.

Single-Screw —- Ideal compression mechanism

A simple construction and water-seal effect deliver ideal operating efficiency.

The “Single-Screw” pump’s construction use a single screw rotor and two gate rotors, one placed on either side of the screw rotor.

This is simple construction transmits pressure to the rotating axle with good balance, and prevents excessive load on the bearings this is one of the reasons for the “Single-Screw” pump’s high efficiency. The water used as a lubricating medium also seals gaps inside the compression chamber.

Compressed air is thus kept from leaking, enabling the “Single-Screw” pump to generate sufficient discharge even at low rotating speeds. This reduces both noise and vibration. The cooling effect of the water lubricant also prevent heating from the compression process (the discharge air temperature is about 40℃.), making the compression process more efficient and eliminating the need for a cooling apparatus.

This improves both safety and durability significantly. The fusion of our unique compression mechanism and new water – lubricant technology is helping greatly to improve energy in a wide range of fields.

Precision processing techniques of high reliability

The center of the rotor has characteristics of SINGLE-SCREW consumption structure that shows high efficiency and stability by utilizing super precision technology of Mitsui Seiki that is also a maker of machine tools.

| Model | KWI-7.5A | KWI-11A | KWI-15A | KWI-18.5A | KWI-22A | KWI-30A | |||||||||||||||||||

| Working Pressure | psig | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 181 |

| bar | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 12.5 | |

| Air Delivery | cfm | 38.8 | 35.3 | 30.0 | 24.7 | 63.6 | 58.3 | 53.0 | 45.9 | 84.7 | 77.7 | 74.2 | 63.6 | 109.5 | 102.4 | 95.3 | 81.2 | 134.2 | 127.1 | 113.0 | 88.3 | 187.1 | 176.6 | 151.8 | 127.1 |

| m3/min | 1.1 | 1 | 0.85 | 0.7 | 1.8 | 1.65 | 1.5 | 1.3 | 2.4 | 2.2 | 2.1 | 1.8 | 3.1 | 2.9 | 2.7 | 2.3 | 3.8 | 3.6 | 3.2 | 2.5 | 5.3 | 5 | 4.3 | 3.6 | |

| Motor Power | kw/hp | 7.5/10 | 11/15 | 15/20 | 18.5/25 | 22/30 | 30/40 | ||||||||||||||||||

| Type of Cooling | Air Cooling / Water Cooling | ||||||||||||||||||||||||

| Motor Power (L*W*H)(mm) | 1300*800*1300 | 1300*800*1300 | 1620*1004*1410 | 1600*910*1350 | 1450*1000*1560 | 1950*1050*1432 | |||||||||||||||||||

| Weight(kg) | 500 | 540 | 650 | 840 | 870 | 980 | |||||||||||||||||||

| Output pipe Diameter | 3/4″ | 1″ | 1″ | 1″ | 1″ | 11/4″ | |||||||||||||||||||

| Model | KWI-37A | KWI-45A | KWI-55A | KWI-75A | KWI-90A | KWI-110W | ||||||||||||||||

| Working Pressure | psig | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 181 | 100 | 116 | 145 | 100 | 116 | 145 | 100 | 116 | 145 |

| bar | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 12.5 | 7 | 8 | 10 | 7 | 8 | 10 | 7 | 8 | 10 | |

| Air Delivery | cfm | 233.0 | 218.9 | 201.3 | 162.4 | 282.5 | 271.9 | 243.6 | 211.9 | 370.8 | 346.0 | 307.2 | 257.8 | 480.2 | 459.0 | 409.6 | 572.0 | 547.3 | 494.3 | 734.4 | 688.5 | 582.6 |

| m3/min | 6.6 | 6.2 | 5.7 | 4.6 | 8 | 7.7 | 6.9 | 6 | 10.5 | 9.8 | 8.7 | 7.3 | 13.6 | 13 | 11.6 | 16.2 | 15.5 | 14 | 20.8 | 19.5 | 16.5 | |

| Motor Power | kw/hp | 37/50 | 45/60 | 55/75 | 75/100 | 90/120 | 110/150 | |||||||||||||||

| Type of Cooling | Air Cooling / Water Cooling | |||||||||||||||||||||

| Motor Power (L*W*H)(mm) | 1700*1100*1630 | 2150*1300*1590 | 2200*1400*1540 | 2400*1450*1740 | 2550*1400*1605 | 2700*1550*1750 | ||||||||||||||||

| Weight(kg) | 1000 | 1060 | 1250 | 1480 | 2030 | 2450 | ||||||||||||||||

| Output pipe Diameter | 11/4″ | 11/2″ | 2″ | 2″ | DN50 | DN65 | ||||||||||||||||

| Model | KWI-132W | KWI-160W | KWI-200W | KWI-250W | KWI-280W | KWI-315W | KWI-400W | |||||||||||||||

| Working Pressure | psig | 100 | 116 | 145 | 100 | 116 | 145 | 100 | 116 | 145 | 100 | 116 | 145 | 100 | 116 | 145 | 100 | 116 | 145 | 100 | 116 | 145 |

| bar | 7 | 8 | 10 | 7 | 8 | 10 | 7 | 8 | 10 | 7 | 8 | 10 | 7 | 8 | 10 | 7 | 8 | 10 | 7 | 8 | 10 | |

| Air Delivery | cfm | 847.7 | 812.1 | 706.2 | 981.6 | 935.7 | 829.8 | 1218.2 | 1165.2 | 988.7 | 1518.3 | 1412.4 | 1306.5 | 1800.8 | 1765.5 | 1589.0 | 1977.4 | 1942.1 | 1730.2 | 2259.8 | 2471.7 | 2153.9 |

| m3/min | 24 | 23 | 20 | 27.8 | 26.5 | 23.5 | 34.5 | 33 | 28 | 43 | 40 | 37 | 51 | 50 | 45 | 56 | 55 | 49 | 64 | 70 | 61 | |

| Motor Power | kw/hp | 132/175 | 160/200 | 200/270 | 250/330 | 280/375 | 315/420 | 400/550 | ||||||||||||||

| Type of Cooling | Air Cooling / Water Cooling | |||||||||||||||||||||

| Motor Power (L*W*H)(mm) | 2600*1650*1750 | 3300*2200*2000 | 3300*2200*2200 | 3670*2070*2370 | 4000*2000*2100 | 4600*2300*2400 | 4600*2300*2400 | |||||||||||||||

| Weight(kg) | 2850 | 3750 | 4100 | 4750 | ||||||||||||||||||

| Output pipe Diameter | DN65 | DN65 | DN80 | DN125 | DN150 | DN125 | DN150 | |||||||||||||||

| Model | KWI-450W | KWI-500W | |||||

| Working Pressure | psig | 100 | 116 | 145 | 100 | 116 | 145 |

| bar | 7 | 8 | 10 | 7 | 8 | 10 | |

| Air Delivery | cfm | 2860.1 | 2789.5 | 2471.7 | 3142.6 | 3072.0 | 2718.9 |

| m3/min | 81 | 79 | 70 | 89 | 87 | 77 | |

| Motor Power | kw/hp | 450/600 | 500/670 | ||||

| Type of Cooling | Air Cooling / Water Cooling | ||||||

| Motor Power (L*W*H)(mm) | 5500*2590*2800 | 5500*2590*2800 | |||||

| Weight(kg) | |||||||

| Output pipe Diameter | DN175 | DN200 | |||||

You May Also Like

KOP Series Oil Free Diesel Portable Air Compressor;

12 – 48m3/min

Working Pressure: 7 – 10.3bar

Learn More >>

KUW Series Silent Oil Free Scroll Air Compressor

140 – 4100L/min

Working Pressure: 7 – 10bar

Learn More >>

KDOF Series Oil Free Dry Screw Air Compressor

7.98 – 58.44m3/min

Working Pressure: 11bar

Learn More >>

KSB Series

Low Pressure Oil Free Air Blower

1500 – 4040m3/min

Working Pressure: 0.5 – 2.5bar

Learn More >>