KSB Series

Low Pressure Oil Free Screw Air Blower

KSB Series Low Pressure Oil Free Screw Air Blower provides customized solutions for cooling and ventilation for any industrial need.

From small business applications to large factories and even residential projects, the KSB Series Low Pressure Oil Free Screw Air Blower will keep your operation running smoothly and efficiently.

Social Sharing:

Performance introduction of KSB Series oil-free screw blower

- Integrated cabinet design, no embedded foundation required, easy installation

- Inlet air filter, blower, motor, muffler, lubrication and cooling system, start-up and control cabinet are all built into the soundproof box

- Forced circulation lubrication cooling system, more reliable

- Intelligent PLC control system, touch screen; can also support remote control of upper computer, and remote monitoring of wireless Internet of Things

- Optimized sound insulation design, making its noise as low as 73 ~ 85dB (A)

- Humanized design, convenient and simple operation and maintenance

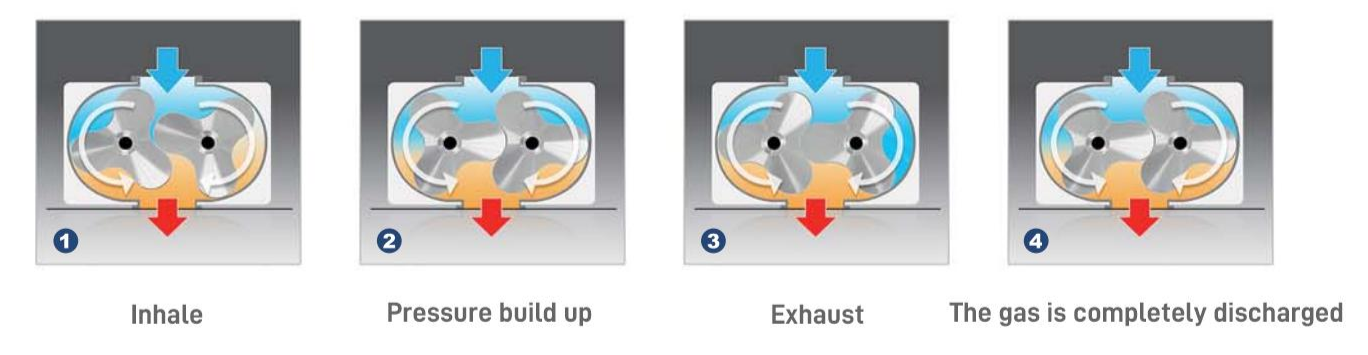

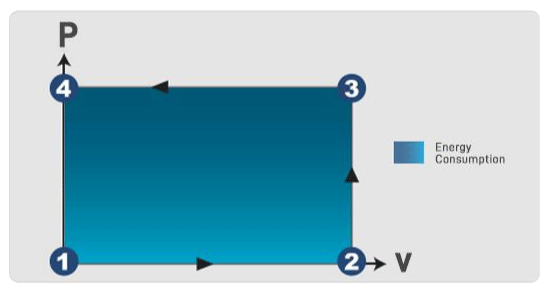

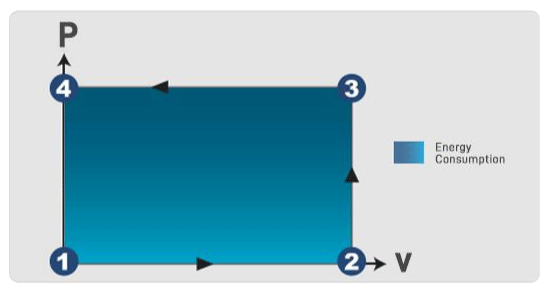

Operation principle and energy consumption diagram of Roots blower

The corresponding states in P-V diagram are:

- Suction air enters the blower from atmosphere or pipe.

- The air is forced to the pressure end by the blower and mixed withthe air leaked back from the exhaust end.

- The exhaust air is further forced to the exhaust end by the blower,and the air is discharged to the pipeline.

- The air is completely discharged, and the air leaves the blowercavity and is completely discharged into the pipe.

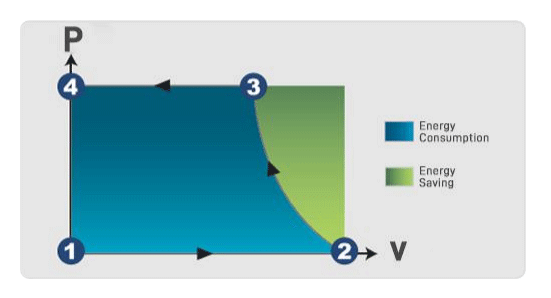

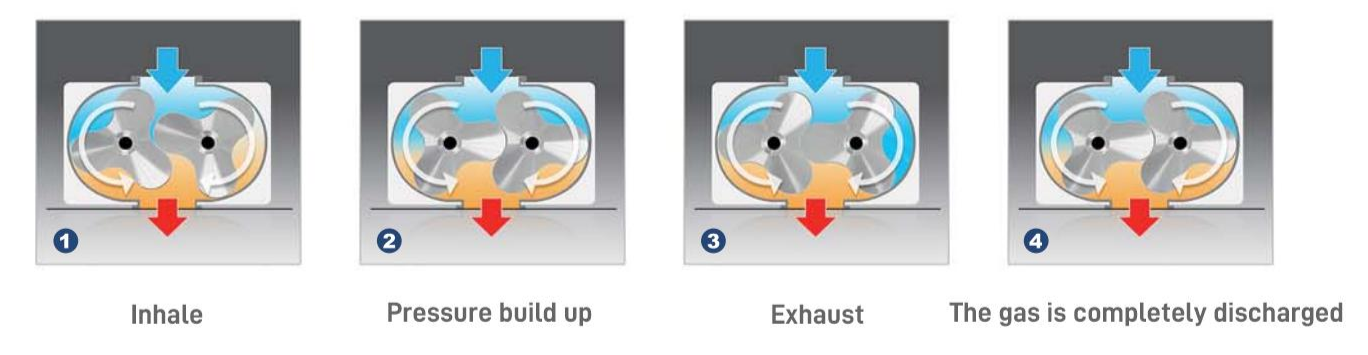

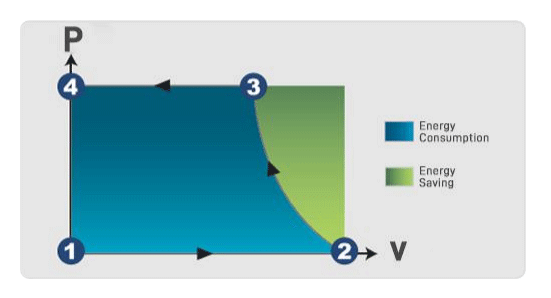

Operating principle and energy consumption diagram of screw blower

The corresponding states in P-V diagram are:

- Suction air enters the blower from atmosphere or pipe.

- The air is forced to the pressure side by the blower.

- The decrease of air volume leads to the increase of pressure.

- Compressed air discharge.

Performance of KSB series oil-free screw blower air end

- Oil-free double-screw air end designed for blowers

- Optimized profile design for higher efficiency

- Advanced coating technology makes the rotor gap smaller, improves the volumetric efficiency, and effectively protects the rotor for longer life

- Adopt international 5-level precision synchronous gear and drive gear to ensure reliability and extend service life

- Unique lubrication and oil discharge channels ensure that bearings and gears are well lubricated and cooled, while improving the efficiency of the host

- The combination of labyrinth seal and carbon ring seal achieves oil and gas isolation between the compression chamber and the lubrication chamber, ensuring that the air is 100% oil-free

- Because the compressed gas has no oil roller slip, the whole system does not need oil and gas separation, and the structure is simpler.

Performance advantages of oil-free screw blowers

The screw blower uses a pair of meshing helical rotors. During rotation, air is sucked in from the intake end, compressed, and discharged to the exhaust end. There is no lubricating oil in the compression chamber, and the male and female rotors are synchronously operated by the synchronous gear.

Compared with traditional blowers, screw blowers have the following performance advantages:

- Low energy consumption: The screw blower is based on the principle of absolute compression, with a total efficiency of more than 75%, which is 20% -30% more energy-efficient than a Roots fan.

- Low noise: The aerodynamic noise of the screw rotor is small, and the output is smooth, eliminating the sudden release of the internal air. The wave-shaped inlet and the air outlet minimize the air flow fluctuations. The advanced structural design reduces the mechanical noise, and the fan sound is less than traditional Blower.

- Flexibility: multiple types of driving methods, higher exhaust pressure, lower pressure pulses

- Low cost: The optimized structural design enables us to consume less and ensure the durability of the product. At the same time, the unit covers a small area and requires no special infrastructure to maximize customer benefits.

| Working Pressure | Model | KSB-20 | KSB-40 | ||||||||||||

| Speed | 1800 | 2200 | 2500 | 3000 | 3500 | 4000 | 4500 | 5000 | 5500 | 1800 | 2200 | 2500 | 3000 | 3500 | |

| 0.5Bar | Air Delivery(m3/h) | 431.36 | 562.4 | 660.2 | 832.0 | 985.7 | 1148.5 | 1311.2 | 1473.9 | 1636.7 | 903.3 | 1157.7 | 1348.3 | 1666.5 | 1983.8 |

| Shaft Power(kw) | 7.4 | 9.2 | 10.6 | 13.1 | 15.8 | 18.7 | 22.0 | 25.5 | 29.4 | 14.7 | 18.4 | 21.4 | 26.8 | 32.8 | |

| Motor Power(kw) | 11 | 11 | 15 | 15 | 18.5 | 22 | 30 | 30 | 37 | 18.5 | 22 | 30 | 30 | 37 | |

| 0.6Bar | Air Delivery(m3/h) | 417.2 | 546.9 | 644.8 | 807.5 | 971.3 | 1134.0 | 1296.8 | 1459.5 | 1622.3 | 879.6 | 1134.0 | 1324.6 | 1642.9 | 1961.1 |

| Shaft Power(kw) | 8.7 | 10.8 | 12.4 | 15.2 | 18.2 | 21.5 | 25.0 | 28.8 | 32.9 | 17.3 | 21.6 | 24.9 | 30.9 | 37.5 | |

| Motor Power(kw) | 11 | 15 | 15 | 18.5 | 22 | 30 | 30 | 37 | 37 | 22 | 30 | 30 | 37 | 45 | |

| 0.7Bar | Air Delivery(m3/h) | 403.8 | 533.5 | 631.4 | 794.1 | 956.9 | 1119.6 | 1283.4 | 1446.1 | 1608.9 | 859.0 | 1113.4 | 1304.1 | 1622.3 | 1939.5 |

| Shaft Power(kw) | 10.0 | 12.4 | 14.2 | 17.3 | 20.7 | 24.2 | 28.0 | 32.1 | 36.5 | 19.9 | 24.7 | 28.4 | 35.1 | 42.2 | |

| Motor Power(kw) | 15 | 15 | 18.5 | 22 | 30 | 30 | 37 | 37 | 45 | 30 | 30 | 37 | 45 | 55 | |

| 0.8Bar | Air Delivery(m3/h) | 391.4 | 521.2 | 619.0 | 781.8 | 944.5 | 1107.3 | 1270.0 | 1432.7 | 1596.5 | 838.4 | 1092.8 | 1284.4 | 1601.7 | 1920.0 |

| Shaft Power(kw) | 11.4 | 14.0 | 16.0 | 19.5 | 23.1 | 27.0 | 31.1 | 35.4 | 40.1 | 22.5 | 27.8 | 32.0 | 39.2 | 46.9 | |

| Motor Power(kw) | 15 | 18.5 | 18.5 | 22 | 30 | 37 | 37 | 45 | 45 | 30 | 37 | 37 | 45 | 55 | |

| 1.0Bar | Air Delivery(m3/h) | 367.7 | 498.5 | 596.4 | 759.1 | 921.9 | 1084.6 | 1247.3 | 1410.1 | 1572.8 | 802.4 | 1056.8 | 1248.4 | 1565.6 | 1883.9 |

| Shaft Power(kw) | 13.1 | 16.3 | 18.7 | 23.0 | 27.5 | 32.4 | 37.7 | 43.5 | 49.7 | 26.0 | 32.3 | 37.3 | 46.0 | 55.6 | |

| Motor Power(kw) | 15 | 18.5 | 22 | 30 | 37 | 37 | 45 | 55 | 75 | 30 | 37 | 45 | 55 | 75 | |

| 1.2Bar | Air Delivery(m3/h) | 347.1 | 476.9 | 574.7 | 737.5 | 901.3 | 1064.0 | 1226.7 | 1389.5 | 1552.2 | 770.4 | 1024.9 | 1215.4 | 1533.7 | 1850.9 |

| Shaft Power(kw) | 15.4 | 19.0 | 21.8 | 26.6 | 31.7 | 37.1 | 42.8 | 49.0 | 55.6 | 30.4 | 37.7 | 43.3 | 53.1 | 63.6 | |

| Motor Power(kw) | 18.5 | 22 | 30 | 30 | 37 | 45 | 55 | 55 | 75 | 37 | 45 | 55 | 75 | 75 | |

| 1.5Bar | Air Delivery(m3/h) | 319.3 | 449.1 | 546.9 | 709.7 | 872.4 | 1035.2 | 1197.9 | 1360.6 | 1524.4 | 726.2 | 980.6 | 1171.1 | 1489.4 | 1806.6 |

| Shaft Power(kw) | 18.9 | 23.2 | 26.5 | 32.1 | 38.0 | 44.2 | 50.6 | 57.4 | 64.7 | 37.1 | 45.7 | 52.3 | 63.7 | 75.7 | |

| Motor Power(kw) | 22 | 30 | 30 | 37 | 45 | 55 | 75 | 75 | 75 | 45 | 55 | 75 | 75 | 90 | |

| 1.8Bar | Air Delivery(m3/h) | 293.6 | 423.3 | 521.2 | 683.9 | 846.7 | 1009.4 | 1173.2 | 1335.9 | 1498.7 | 686.0 | 940.4 | 1130.9 | 1449.2 | 1767.5 |

| Shaft Power(kw) | 22.3 | 27.3 | 31.2 | 37.7 | 44.4 | 51.3 | 58.5 | 66.0 | 73.9 | 43.8 | 53.8 | 61.4 | 74.5 | 88.0 | |

| Motor Power(kw) | 30 | 37 | 37 | 45 | 55 | 75 | 75 | 75 | 90 | 55 | 75 | 75 | 90 | 110 | |

| 2.0Bar | Air Delivery(m3/h) | 277.1 | 407.9 | 505.7 | 668.5 | 831.2 | 994.0 | 1156.7 | 1319.4 | 1482.2 | 661.3 | 915.7 | 1106.2 | 1424.5 | 1741.7 |

| Shaft Power(kw) | 22.3 | 27.4 | 31.4 | 38.2 | 45.3 | 52.8 | 60.7 | 69.1 | 78.0 | 43.8 | 54.2 | 62.2 | 76.2 | 91.0 | |

| Motor Power(kw) | 30 | 37 | 37 | 45 | 55 | 75 | 75 | 90 | 90 | 55 | 75 | 75 | 90 | 110 | |

| 2.5Bar | Air Delivery(m3/h) | 252.6 | 371.8 | 468.7 | 631.4 | 795.2 | 957.9 | 1120.6 | 1283.4 | 1446.1 | 603.6 | 858.0 | 1049.6 | 1366.8 | 1685.1 |

| Shaft Power(kw) | 22.3 | 33.1 | 37.8 | 45.7 | 54.0 | 62.5 | 71.3 | 80.6 | 90.3 | 52.9 | 65.1 | 74.5 | 90.5 | 107.3 | |

| Motor Power(kw) | 30 | 37 | 45 | 55 | 75 | 75 | 90 | 90 | 110 | 75 | 75 | 90 | 110 | 132 | |

| Working Pressure | Model | KSB-40 | KSB-70 | KSB-100 | |||||||||||

| Speed | 4000 | 4500 | 1800 | 2200 | 2500 | 3000 | 3500 | 3600 | 3800 | 1800 | 2200 | 2500 | 2800 | 3000 | |

| 0.5Bar | Air Delivery(m3/h) | 2302.1 | 2620.3 | 2005.4 | 2539.0 | 2938.6 | 3605.0 | 4272.4 | 4405.3 | 4672.1 | 4071.6 | 5111.9 | 5893.7 | 6676.5 | 7195.6 |

| Shaft Power(kw) | 39.5 | 47.0 | 31.4 | 39.7 | 46.4 | 58.8 | 72.9 | 75.9 | 82.2 | 64.7 | 83.9 | 100.1 | 118.1 | 131.1 | |

| Motor Power(kw) | 45 | 55 | 37 | 45 | 55 | 75 | 90 | 90 | 90 | 75 | 110 | 110 | 132 | 160 | |

| 0.6Bar | Air Delivery(m3/h) | 2279.4 | 2596.6 | 1967.3 | 2500.8 | 2900.5 | 3567.9 | 4234.3 | 4368.2 | 4635.0 | 4011.9 | 5052.2 | 5836.0 | 6615.7 | 7137.9 |

| Shaft Power(kw) | 44.7 | 52.7 | 36.7 | 46.1 | 53.5 | 67.1 | 82.2 | 85.4 | 92.1 | 74.9 | 95.8 | 113.3 | 132.4 | 146.3 | |

| Motor Power(kw) | 55 | 75 | 45 | 55 | 75 | 75 | 90 | 110 | 110 | 90 | 110 | 132 | 160 | 160 | |

| 0.7Bar | Air Delivery(m3/h) | 2257.8 | 2576.0 | 1932.3 | 2465.8 | 2866.5 | 3532.9 | 4200.3 | 4333.2 | 4600.0 | 3958.3 | 4998.6 | 5780.4 | 6563.2 | 7083.3 |

| Shaft Power(kw) | 49.9 | 58.4 | 42.1 | 52.5 | 60.7 | 75.4 | 91.6 | 95.1 | 102.1 | 85.0 | 107.9 | 126.7 | 147.0 | 161.5 | |

| Motor Power(kw) | 75 | 75 | 55 | 75 | 75 | 90 | 110 | 110 | 132 | 110 | 132 | 160 | 160 | 200 | |

| 0.8Bar | Air Delivery(m3/h) | 2238.2 | 2555.4 | 1900.4 | 2433.9 | 2833.5 | 3501.0 | 4167.4 | 4301.3 | 4568.1 | 3907.8 | 4949.2 | 5728.9 | 6512.7 | 7032.8 |

| Shaft Power(kw) | 55.2 | 64.1 | 47.4 | 58.9 | 67.9 | 83.8 | 101.1 | 104.7 | 112.2 | 95.3 | 120.0 | 140.1 | 161.7 | 176.9 | |

| Motor Power(kw) | 75 | 75 | 55 | 75 | 90 | 110 | 110 | 132 | 132 | 110 | 132 | 160 | 200 | 200 | |

| 1.0Bar | Air Delivery(m3/h) | 2202.1 | 2519.4 | 1841.6 | 2374.2 | 2774.8 | 3442.3 | 4108.7 | 4242.6 | 4508.3 | 3815.1 | 4857.5 | 5638.2 | 6420.0 | 6941.2 |

| Shaft Power(kw) | 66.0 | 77.4 | 54.9 | 68.8 | 79.9 | 99.8 | 121.9 | 126.6 | 136.3 | 111.4 | 142.0 | 167.2 | 194.6 | 214.2 | |

| Motor Power(kw) | 75 | 90 | 75 | 90 | 90 | 110 | 132 | 160 | 160 | 132 | 160 | 200 | 250 | 250 | |

| 1.2Bar | Air Delivery(m3/h) | 2169.2 | 2487.5 | 1788.1 | 2321.6 | 2721.3 | 3388.7 | 4055.1 | 4189.0 | 4455.8 | 3731.7 | 4774.1 | 5554.8 | 6336.6 | 6857.7 |

| Shaft Power(kw) | 74.9 | 87.1 | 64.0 | 79.6 | 91.9 | 113.8 | 137.5 | 142.6 | 152.9 | 128.5 | 162.2 | 189.5 | 218.8 | 239.5 | |

| Motor Power(kw) | 90 | 110 | 75 | 90 | 110 | 132 | 160 | 160 | 200 | 160 | 200 | 250 | 250 | 315 | |

| 1.5Bar | Air Delivery(m3/h) | 2124.9 | 2443.2 | 1716.0 | 2248.5 | 2649.2 | 3316.6 | 3983.0 | 4115.9 | 4382.7 | 3618.4 | 4660.8 | 5441.5 | 6223.3 | 6744.4 |

| Shaft Power(kw) | 88.4 | 101.8 | 77.6 | 95.9 | 110.1 | 135.0 | 161.4 | 166.9 | 178.2 | 154.4 | 192.9 | 223.4 | 255.8 | 278.4 | |

| Motor Power(kw) | 110 | 132 | 90 | 110 | 132 | 160 | 200 | 200 | 200 | 200 | 250 | 250 | 315 | 315 | |

| 1.8Bar | Air Delivery(m3/h) | 2084.7 | 2403.0 | 1650.1 | 2183.6 | 2583.2 | 3250.7 | 3917.1 | 4051.0 | 4317.8 | 3516.4 | 4557.8 | 5339.5 | 6121.3 | 6642.5 |

| Shaft Power(kw) | 102.0 | 116.8 | 91.2 | 112.2 | 128.4 | 156.3 | 185.6 | 191.7 | 203.9 | 180.5 | 223.8 | 257.9 | 293.4 | 317.9 | |

| Motor Power(kw) | 132 | 132 | 110 | 132 | 160 | 200 | 250 | 250 | 250 | 200 | 250 | 315 | 355 | 355 | |

| 2.0Bar | Air Delivery(m3/h) | 2060.0 | 2378.3 | 1609.9 | 1876.7 | 2543.1 | 3210.5 | 3876.9 | 4010.8 | 4277.6 | 3452.6 | 4492.9 | 5276.7 | 6057.4 | 6578.6 |

| Shaft Power(kw) | 106.8 | 123.8 | 92.9 | 104.1 | 133.4 | 165.0 | 199.3 | 206.5 | 221.3 | 185.5 | 233.3 | 272.0 | 313.0 | 339.8 | |

| Motor Power(kw) | 132 | 160 | 110 | 132 | 160 | 200 | 250 | 250 | 250 | 250 | 315 | 315 | 355 | 400 | |

| 2.5Bar | Air Delivery(m3/h) | 2003.4 | 2320.6 | 1516.2 | 1782.9 | 2450.4 | 3116.8 | 3784.2 | 3917.1 | 4183.9 | 3307.3 | 4343.7 | 5130.4 | 5912.2 | 6432.4 |

| Shaft Power(kw) | 124.9 | 143.5 | 111.4 | 124.4 | 158.1 | 193.6 | 231.3 | 239.2 | 255.2 | 220.7 | 274.9 | 317.9 | 361.4 | 392.3 | |

| Motor Power(kw) | 160 | 160 | 132 | 160 | 200 | 250 | 315 | 315 | 315 | 250 | 315 | 355 | 400 | 450 | |

KSB Series Screw Air Blower Applications

You May Also Like

KOP Series Oil Free Diesel Portable Air Compressor;

12 – 48m3/min

Working Pressure: 7 – 10.3bar

Learn More >>

KUW Series

Silent Oil Free Scroll Air Compressor

140 – 4100L/min

Working Pressure: 7 – 10bar

Learn More >>

KWI Series Oil Free Water Lubricated Screw Air Compressor

1.1 – 77m3/min

Working Pressure: 7 – 12.5bar

Learn More >>

KDOF Series Oil Free Dry Screw Air Compressor

7.98 – 58.44m3/min

Working Pressure: 7 – 11bar

Learn More >>

Performance introduction of KSB Series oil-free screw blower

- Integrated cabinet design, no embedded foundation required, easy installation

- Inlet air filter, blower, motor, muffler, lubrication and cooling system, start-up and control cabinet are all built into the soundproof box

- Forced circulation lubrication cooling system, more reliable

- Intelligent PLC control system, touch screen; can also support remote control of upper computer, and remote monitoring of wireless Internet of Things

- Optimized sound insulation design, making its noise as low as 73 ~ 85dB (A)

- Humanized design, convenient and simple operation and maintenance

Operation principle and energy consumption diagram of Roots blower

The corresponding states in P-V diagram are:

- Suction air enters the blower from atmosphere or pipe.

- The air is forced to the pressure end by the blower and mixed withthe air leaked back from the exhaust end.

- The exhaust air is further forced to the exhaust end by the blower,and the air is discharged to the pipeline.

- The air is completely discharged, and the air leaves the blowercavity and is completely discharged into the pipe.

Operating principle and energy consumption diagram of screw blower

The corresponding states in P-V diagram are:

- Suction air enters the blower from atmosphere or pipe.

- The air is forced to the pressure side by the blower.

- The decrease of air volume leads to the increase of pressure.

- Compressed air discharge.

Performance of KSB series oil-free screw blower air end

- Oil-free double-screw air end designed for blowers

- Optimized profile design for higher efficiency

- Advanced coating technology makes the rotor gap smaller, improves the volumetric efficiency, and effectively protects the rotor for longer life

- Adopt international 5-level precision synchronous gear and drive gear to ensure reliability and extend service life

- Unique lubrication and oil discharge channels ensure that bearings and gears are well lubricated and cooled, while improving the efficiency of the host

- The combination of labyrinth seal and carbon ring seal achieves oil and gas isolation between the compression chamber and the lubrication chamber, ensuring that the air is 100% oil-free

- Because the compressed gas has no oil roller slip, the whole system does not need oil and gas separation, and the structure is simpler.

Performance advantages of oil-free screw blowers

The screw blower uses a pair of meshing helical rotors. During rotation, air is sucked in from the intake end, compressed, and discharged to the exhaust end. There is no lubricating oil in the compression chamber, and the male and female rotors are synchronously operated by the synchronous gear.

Compared with traditional blowers, screw blowers have the following performance advantages:

- Low energy consumption: The screw blower is based on the principle of absolute compression, with a total efficiency of more than 75%, which is 20% -30% more energy-efficient than a Roots fan.

- Low noise: The aerodynamic noise of the screw rotor is small, and the output is smooth, eliminating the sudden release of the internal air. The wave-shaped inlet and the air outlet minimize the air flow fluctuations. The advanced structural design reduces the mechanical noise, and the fan sound is less than traditional Blower.

- Flexibility: multiple types of driving methods, higher exhaust pressure, lower pressure pulses

- Low cost: The optimized structural design enables us to consume less and ensure the durability of the product. At the same time, the unit covers a small area and requires no special infrastructure to maximize customer benefits.

| Working Pressure | Model | KSB-20 | KSB-40 | ||||||||||||

| Speed | 1800 | 2200 | 2500 | 3000 | 3500 | 4000 | 4500 | 5000 | 5500 | 1800 | 2200 | 2500 | 3000 | 3500 | |

| 0.5Bar | Air Delivery(m3/h) | 431.36 | 562.4 | 660.2 | 832.0 | 985.7 | 1148.5 | 1311.2 | 1473.9 | 1636.7 | 903.3 | 1157.7 | 1348.3 | 1666.5 | 1983.8 |

| Shaft Power(kw) | 7.4 | 9.2 | 10.6 | 13.1 | 15.8 | 18.7 | 22.0 | 25.5 | 29.4 | 14.7 | 18.4 | 21.4 | 26.8 | 32.8 | |

| Motor Power(kw) | 11 | 11 | 15 | 15 | 18.5 | 22 | 30 | 30 | 37 | 18.5 | 22 | 30 | 30 | 37 | |

| 0.6Bar | Air Delivery(m3/h) | 417.2 | 546.9 | 644.8 | 807.5 | 971.3 | 1134.0 | 1296.8 | 1459.5 | 1622.3 | 879.6 | 1134.0 | 1324.6 | 1642.9 | 1961.1 |

| Shaft Power(kw) | 8.7 | 10.8 | 12.4 | 15.2 | 18.2 | 21.5 | 25.0 | 28.8 | 32.9 | 17.3 | 21.6 | 24.9 | 30.9 | 37.5 | |

| Motor Power(kw) | 11 | 15 | 15 | 18.5 | 22 | 30 | 30 | 37 | 37 | 22 | 30 | 30 | 37 | 45 | |

| 0.7Bar | Air Delivery(m3/h) | 403.8 | 533.5 | 631.4 | 794.1 | 956.9 | 1119.6 | 1283.4 | 1446.1 | 1608.9 | 859.0 | 1113.4 | 1304.1 | 1622.3 | 1939.5 |

| Shaft Power(kw) | 10.0 | 12.4 | 14.2 | 17.3 | 20.7 | 24.2 | 28.0 | 32.1 | 36.5 | 19.9 | 24.7 | 28.4 | 35.1 | 42.2 | |

| Motor Power(kw) | 15 | 15 | 18.5 | 22 | 30 | 30 | 37 | 37 | 45 | 30 | 30 | 37 | 45 | 55 | |

| 0.8Bar | Air Delivery(m3/h) | 391.4 | 521.2 | 619.0 | 781.8 | 944.5 | 1107.3 | 1270.0 | 1432.7 | 1596.5 | 838.4 | 1092.8 | 1284.4 | 1601.7 | 1920.0 |

| Shaft Power(kw) | 11.4 | 14.0 | 16.0 | 19.5 | 23.1 | 27.0 | 31.1 | 35.4 | 40.1 | 22.5 | 27.8 | 32.0 | 39.2 | 46.9 | |

| Motor Power(kw) | 15 | 18.5 | 18.5 | 22 | 30 | 37 | 37 | 45 | 45 | 30 | 37 | 37 | 45 | 55 | |

| 1.0Bar | Air Delivery(m3/h) | 367.7 | 498.5 | 596.4 | 759.1 | 921.9 | 1084.6 | 1247.3 | 1410.1 | 1572.8 | 802.4 | 1056.8 | 1248.4 | 1565.6 | 1883.9 |

| Shaft Power(kw) | 13.1 | 16.3 | 18.7 | 23.0 | 27.5 | 32.4 | 37.7 | 43.5 | 49.7 | 26.0 | 32.3 | 37.3 | 46.0 | 55.6 | |

| Motor Power(kw) | 15 | 18.5 | 22 | 30 | 37 | 37 | 45 | 55 | 75 | 30 | 37 | 45 | 55 | 75 | |

| 1.2Bar | Air Delivery(m3/h) | 347.1 | 476.9 | 574.7 | 737.5 | 901.3 | 1064.0 | 1226.7 | 1389.5 | 1552.2 | 770.4 | 1024.9 | 1215.4 | 1533.7 | 1850.9 |

| Shaft Power(kw) | 15.4 | 19.0 | 21.8 | 26.6 | 31.7 | 37.1 | 42.8 | 49.0 | 55.6 | 30.4 | 37.7 | 43.3 | 53.1 | 63.6 | |

| Motor Power(kw) | 18.5 | 22 | 30 | 30 | 37 | 45 | 55 | 55 | 75 | 37 | 45 | 55 | 75 | 75 | |

| 1.5Bar | Air Delivery(m3/h) | 319.3 | 449.1 | 546.9 | 709.7 | 872.4 | 1035.2 | 1197.9 | 1360.6 | 1524.4 | 726.2 | 980.6 | 1171.1 | 1489.4 | 1806.6 |

| Shaft Power(kw) | 18.9 | 23.2 | 26.5 | 32.1 | 38.0 | 44.2 | 50.6 | 57.4 | 64.7 | 37.1 | 45.7 | 52.3 | 63.7 | 75.7 | |

| Motor Power(kw) | 22 | 30 | 30 | 37 | 45 | 55 | 75 | 75 | 75 | 45 | 55 | 75 | 75 | 90 | |

| 1.8Bar | Air Delivery(m3/h) | 293.6 | 423.3 | 521.2 | 683.9 | 846.7 | 1009.4 | 1173.2 | 1335.9 | 1498.7 | 686.0 | 940.4 | 1130.9 | 1449.2 | 1767.5 |

| Shaft Power(kw) | 22.3 | 27.3 | 31.2 | 37.7 | 44.4 | 51.3 | 58.5 | 66.0 | 73.9 | 43.8 | 53.8 | 61.4 | 74.5 | 88.0 | |

| Motor Power(kw) | 30 | 37 | 37 | 45 | 55 | 75 | 75 | 75 | 90 | 55 | 75 | 75 | 90 | 110 | |

| 2.0Bar | Air Delivery(m3/h) | 277.1 | 407.9 | 505.7 | 668.5 | 831.2 | 994.0 | 1156.7 | 1319.4 | 1482.2 | 661.3 | 915.7 | 1106.2 | 1424.5 | 1741.7 |

| Shaft Power(kw) | 22.3 | 27.4 | 31.4 | 38.2 | 45.3 | 52.8 | 60.7 | 69.1 | 78.0 | 43.8 | 54.2 | 62.2 | 76.2 | 91.0 | |

| Motor Power(kw) | 30 | 37 | 37 | 45 | 55 | 75 | 75 | 90 | 90 | 55 | 75 | 75 | 90 | 110 | |

| 2.5Bar | Air Delivery(m3/h) | 252.6 | 371.8 | 468.7 | 631.4 | 795.2 | 957.9 | 1120.6 | 1283.4 | 1446.1 | 603.6 | 858.0 | 1049.6 | 1366.8 | 1685.1 |

| Shaft Power(kw) | 22.3 | 33.1 | 37.8 | 45.7 | 54.0 | 62.5 | 71.3 | 80.6 | 90.3 | 52.9 | 65.1 | 74.5 | 90.5 | 107.3 | |

| Motor Power(kw) | 30 | 37 | 45 | 55 | 75 | 75 | 90 | 90 | 110 | 75 | 75 | 90 | 110 | 132 | |

| Working Pressure | Model | KSB-40 | KSB-70 | KSB-100 | |||||||||||

| Speed | 4000 | 4500 | 1800 | 2200 | 2500 | 3000 | 3500 | 3600 | 3800 | 1800 | 2200 | 2500 | 2800 | 3000 | |

| 0.5Bar | Air Delivery(m3/h) | 2302.1 | 2620.3 | 2005.4 | 2539.0 | 2938.6 | 3605.0 | 4272.4 | 4405.3 | 4672.1 | 4071.6 | 5111.9 | 5893.7 | 6676.5 | 7195.6 |

| Shaft Power(kw) | 39.5 | 47.0 | 31.4 | 39.7 | 46.4 | 58.8 | 72.9 | 75.9 | 82.2 | 64.7 | 83.9 | 100.1 | 118.1 | 131.1 | |

| Motor Power(kw) | 45 | 55 | 37 | 45 | 55 | 75 | 90 | 90 | 90 | 75 | 110 | 110 | 132 | 160 | |

| 0.6Bar | Air Delivery(m3/h) | 2279.4 | 2596.6 | 1967.3 | 2500.8 | 2900.5 | 3567.9 | 4234.3 | 4368.2 | 4635.0 | 4011.9 | 5052.2 | 5836.0 | 6615.7 | 7137.9 |

| Shaft Power(kw) | 44.7 | 52.7 | 36.7 | 46.1 | 53.5 | 67.1 | 82.2 | 85.4 | 92.1 | 74.9 | 95.8 | 113.3 | 132.4 | 146.3 | |

| Motor Power(kw) | 55 | 75 | 45 | 55 | 75 | 75 | 90 | 110 | 110 | 90 | 110 | 132 | 160 | 160 | |

| 0.7Bar | Air Delivery(m3/h) | 2257.8 | 2576.0 | 1932.3 | 2465.8 | 2866.5 | 3532.9 | 4200.3 | 4333.2 | 4600.0 | 3958.3 | 4998.6 | 5780.4 | 6563.2 | 7083.3 |

| Shaft Power(kw) | 49.9 | 58.4 | 42.1 | 52.5 | 60.7 | 75.4 | 91.6 | 95.1 | 102.1 | 85.0 | 107.9 | 126.7 | 147.0 | 161.5 | |

| Motor Power(kw) | 75 | 75 | 55 | 75 | 75 | 90 | 110 | 110 | 132 | 110 | 132 | 160 | 160 | 200 | |

| 0.8Bar | Air Delivery(m3/h) | 2238.2 | 2555.4 | 1900.4 | 2433.9 | 2833.5 | 3501.0 | 4167.4 | 4301.3 | 4568.1 | 3907.8 | 4949.2 | 5728.9 | 6512.7 | 7032.8 |

| Shaft Power(kw) | 55.2 | 64.1 | 47.4 | 58.9 | 67.9 | 83.8 | 101.1 | 104.7 | 112.2 | 95.3 | 120.0 | 140.1 | 161.7 | 176.9 | |

| Motor Power(kw) | 75 | 75 | 55 | 75 | 90 | 110 | 110 | 132 | 132 | 110 | 132 | 160 | 200 | 200 | |

| 1.0Bar | Air Delivery(m3/h) | 2202.1 | 2519.4 | 1841.6 | 2374.2 | 2774.8 | 3442.3 | 4108.7 | 4242.6 | 4508.3 | 3815.1 | 4857.5 | 5638.2 | 6420.0 | 6941.2 |

| Shaft Power(kw) | 66.0 | 77.4 | 54.9 | 68.8 | 79.9 | 99.8 | 121.9 | 126.6 | 136.3 | 111.4 | 142.0 | 167.2 | 194.6 | 214.2 | |

| Motor Power(kw) | 75 | 90 | 75 | 90 | 90 | 110 | 132 | 160 | 160 | 132 | 160 | 200 | 250 | 250 | |

| 1.2Bar | Air Delivery(m3/h) | 2169.2 | 2487.5 | 1788.1 | 2321.6 | 2721.3 | 3388.7 | 4055.1 | 4189.0 | 4455.8 | 3731.7 | 4774.1 | 5554.8 | 6336.6 | 6857.7 |

| Shaft Power(kw) | 74.9 | 87.1 | 64.0 | 79.6 | 91.9 | 113.8 | 137.5 | 142.6 | 152.9 | 128.5 | 162.2 | 189.5 | 218.8 | 239.5 | |

| Motor Power(kw) | 90 | 110 | 75 | 90 | 110 | 132 | 160 | 160 | 200 | 160 | 200 | 250 | 250 | 315 | |

| 1.5Bar | Air Delivery(m3/h) | 2124.9 | 2443.2 | 1716.0 | 2248.5 | 2649.2 | 3316.6 | 3983.0 | 4115.9 | 4382.7 | 3618.4 | 4660.8 | 5441.5 | 6223.3 | 6744.4 |

| Shaft Power(kw) | 88.4 | 101.8 | 77.6 | 95.9 | 110.1 | 135.0 | 161.4 | 166.9 | 178.2 | 154.4 | 192.9 | 223.4 | 255.8 | 278.4 | |

| Motor Power(kw) | 110 | 132 | 90 | 110 | 132 | 160 | 200 | 200 | 200 | 200 | 250 | 250 | 315 | 315 | |

| 1.8Bar | Air Delivery(m3/h) | 2084.7 | 2403.0 | 1650.1 | 2183.6 | 2583.2 | 3250.7 | 3917.1 | 4051.0 | 4317.8 | 3516.4 | 4557.8 | 5339.5 | 6121.3 | 6642.5 |

| Shaft Power(kw) | 102.0 | 116.8 | 91.2 | 112.2 | 128.4 | 156.3 | 185.6 | 191.7 | 203.9 | 180.5 | 223.8 | 257.9 | 293.4 | 317.9 | |

| Motor Power(kw) | 132 | 132 | 110 | 132 | 160 | 200 | 250 | 250 | 250 | 200 | 250 | 315 | 355 | 355 | |

| 2.0Bar | Air Delivery(m3/h) | 2060.0 | 2378.3 | 1609.9 | 1876.7 | 2543.1 | 3210.5 | 3876.9 | 4010.8 | 4277.6 | 3452.6 | 4492.9 | 5276.7 | 6057.4 | 6578.6 |

| Shaft Power(kw) | 106.8 | 123.8 | 92.9 | 104.1 | 133.4 | 165.0 | 199.3 | 206.5 | 221.3 | 185.5 | 233.3 | 272.0 | 313.0 | 339.8 | |

| Motor Power(kw) | 132 | 160 | 110 | 132 | 160 | 200 | 250 | 250 | 250 | 250 | 315 | 315 | 355 | 400 | |

| 2.5Bar | Air Delivery(m3/h) | 2003.4 | 2320.6 | 1516.2 | 1782.9 | 2450.4 | 3116.8 | 3784.2 | 3917.1 | 4183.9 | 3307.3 | 4343.7 | 5130.4 | 5912.2 | 6432.4 |

| Shaft Power(kw) | 124.9 | 143.5 | 111.4 | 124.4 | 158.1 | 193.6 | 231.3 | 239.2 | 255.2 | 220.7 | 274.9 | 317.9 | 361.4 | 392.3 | |

| Motor Power(kw) | 160 | 160 | 132 | 160 | 200 | 250 | 315 | 315 | 315 | 250 | 315 | 355 | 400 | 450 | |

KSB Series Screw Air Blower Applications

You May Also Like

KOP Series Oil Free Diesel Portable Air Compressor;

12 – 48m3/min

Working Pressure: 7 – 10.3bar

Learn More >>

KUW Series

Silent Oil Free Scroll Air Compressor

140 – 4100L/min

Working Pressure: 7 – 10bar

Learn More >>

KWI Series Oil Free Water Lubricated Screw Air Compressor

1.1 – 77m3/min

Working Pressure: 7 – 12.5bar

Learn More >>

KDOF Series Oil Free Dry Screw Air Compressor

7.98 – 58.44m3/min

Working Pressure: 7 – 11bar

Learn More >>