What is A Diesel Generator Set? | Working Principle

The Working Principle of Diesel Generator Sets

I. Overview of Diesel Generator Set:

The generator is other forms of energy into electrical energy mechanical equipment, it is driven by the water turbine, steam turbine, diesel engine or other power machinery, water flow, air flow, fuel combustion, or atomic fission energy generated by the mechanical energy to the generator, and then converted by the generator into electrical energy. Generator in industrial and agricultural production, national defense, mining, construction, science and technology, and daily life has a wide range of uses.

The (DG)diesel generator & diesel generator set is a power generation equipment, that refers to the diesel fuel, and the diesel engine as the prime mover to drive the generator power generation machinery.

The whole set is generally composed of a diesel engine, generator, control box, fuel tank, starting and control with battery, protection equipment, emergency cabinet, and other components. Can be used for a variety of families, offices, small and medium-sized enterprises daily power generation, and emergency power generation.

II. The Principle of Diesel Generator Sets

The working principle of a diesel generator is that the diesel engine drives the generator to run.

In the cylinder, the clean air filtered by the air filter and the high-pressure atomized diesel fuel injected by the injector nozzle is fully mixed. Under the upward pressure of the piston, the volume decreases and the temperature rises rapidly, reaching the ignition point of diesel fuel.

Diesel fuel is ignited, the mixture burns violently, and its volume expands rapidly, pushing the piston downward movement. Each cylinder works sequentially in a certain order, and the thrust acting on the piston becomes the force that pushes the crankshaft to rotate through the connecting rod, thus driving the crankshaft to rotate.

The brushless synchronous alternator is installed coaxially with the crankshaft of the diesel engine, it can use the diesel engine’s turning to drive the rotor of the generator, using the principle of ‘electromagnetic induction’, the generator will output the induced electromotive force, and the current can be generated by the closed load circuit.

Diesel Generator Set Structure Composition

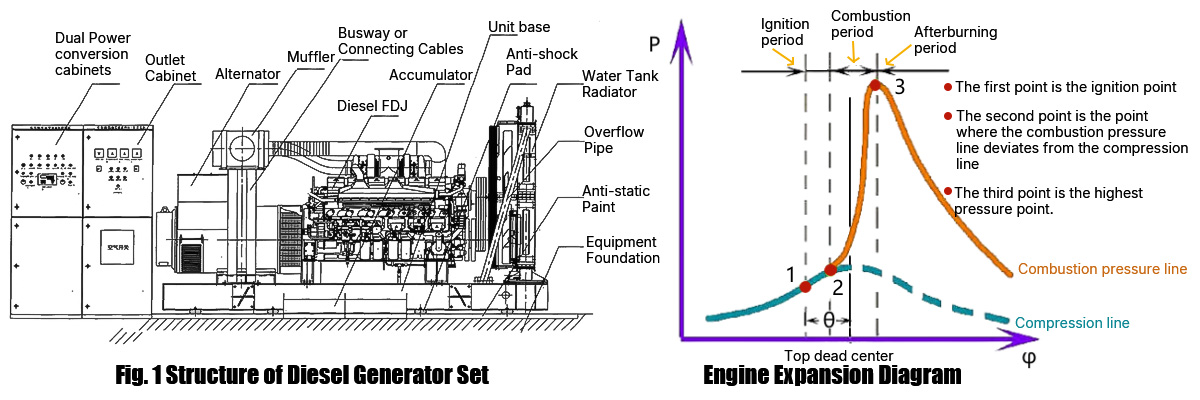

A diesel generator complete set is generally composed of a diesel engine, generator, control box, fuel tank, starting and control battery, protection devices, emergency cabinets, and other components, the structure shown in Figure 1.

Diesel Generator – Diesel Engine

The diesel engine is mainly composed of cylinders, pistons, crankshafts, connecting rods, intake tracts, exhaust tracts, injectors, and so on. Among them, the cylinder is one of the most important parts of the diesel engine, which is a cylindrical container with a piston and a combustion chamber inside. The crankshaft, on the other hand, is the key component that converts the reciprocating motion of the piston into rotary motion.

In the diesel engine cylinder, after the air filter filters clean air and injector nozzle injection of high-pressure atomized diesel fuel is Fully mixed, in the piston upward pressure, the volume is reduced, and the temperature rises rapidly, reaching the ignition point of diesel fuel. Diesel fuel is ignited, the mixture of gas combustion, the volume of rapid expansion, pushing the piston downward, known as the ‘work’, work diagram is shown in Figure 2.

Each cylinder in a certain order in turn works, the thrust acting on the piston through the connecting rod into a force that pushes the crankshaft to rotate, thus driving the crankshaft rotation.

Diesel Engine Power Unit Conversion

Power conversion formula:

1hp=0.735kW

Are you looking for a reliable and efficient power source for your industry? Kotech dealers are experienced in finding the perfect air compressor for your needs.

Contact your local Kotech dealer today and discover how an air compressor can increase your productivity and safety.

Generator

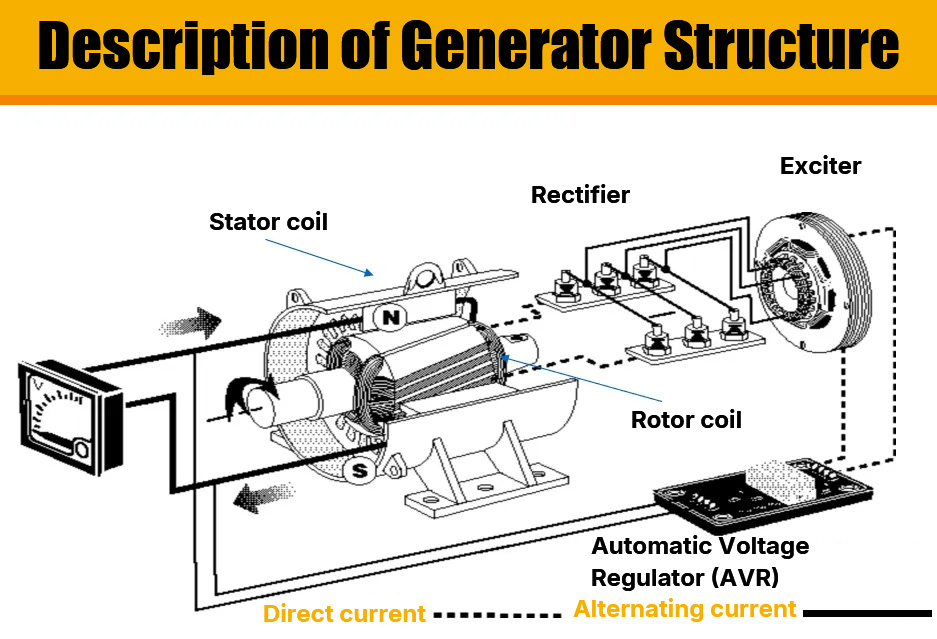

The generators commonly used in diesel generator sets are synchronous alternators, which are rotating machines based on electromagnetic induction. According to its structural characteristics can be divided into rotating armature type and rotating magnetic pole type two.

The brushless synchronous alternator is installed coaxially with the crankshaft of the diesel engine, you can use the rotation of the diesel engine to drive the rotor of the generator, and using the principle of ‘electromagnetic induction’, the generator will output the induced electromotive force, and the current can be generated by the closed load circuit.

What is A Diesel Generator Set?

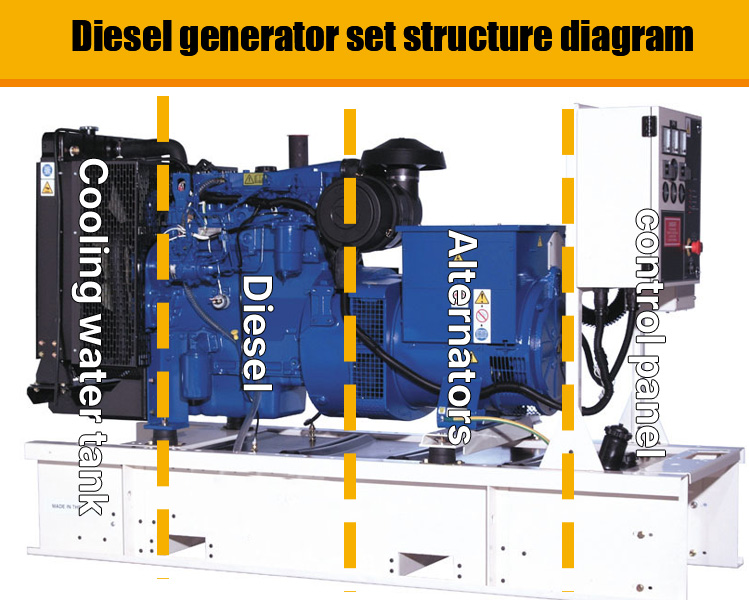

The so-called diesel generator set is a diesel engine as a power plant to drive the alternator to achieve the mechanical energy converted into electrical energy electromechanical equipment. Because of the high temperatures generated when the unit is in operation, a cooling system must be used.

The cooling water tank is precisely to achieve the flow through the body after the high temperature cooling water to cool down the components. Depending on the control panel model, the unit can be controlled manually or automatically. The base of the unit is to provide support and stabilization for the unit.

Diesel engine stroke:

Every diesel engine after four thermal processes of intake, compression, expansion, and exhaust, is known as a working cycle. A piston from the upper stop to the lower stop, or from the lower stop to the upper stop is called a stroke.

If the piston completes a cycle after every four strokes, the engine is called a four-stroke diesel engine. If the piston completes one cycle after two strokes, the engine is called a two-stroke diesel engine.

Exhaust gas turbocharging:

It refers to the use of diesel engine exhaust gas to drive the supercharger, the air is compressed and then sent to the cylinder of a kind of supercharging. This increases the oxygen density of the intake air and improves the combustion and explosive capacity of the diesel fuel in the diesel engine.

Compared with the diesel engine without supercharger can be increased by more than 30% of the working capacity, and can reduce the shape of the size, saving raw materials.

Cooling:

The high-temperature air after supercharging is not conducive to the work of the diesel engine, so the high-temperature air must be cooled down, which is called cooling.

Cylinder arrangement:

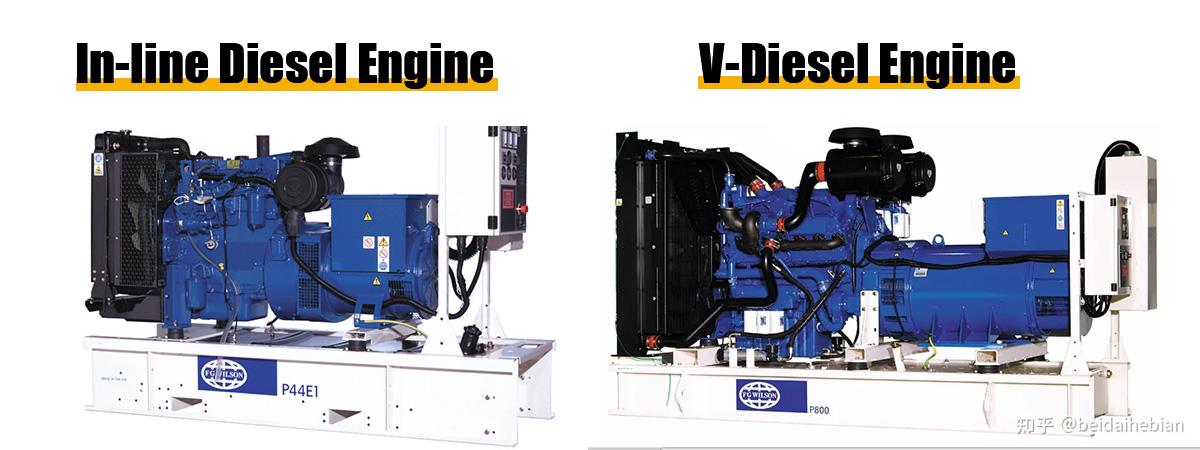

The arrangement of cylinders in a diesel engine is called cylinder arrangement. Divided into in-line and V-type two.

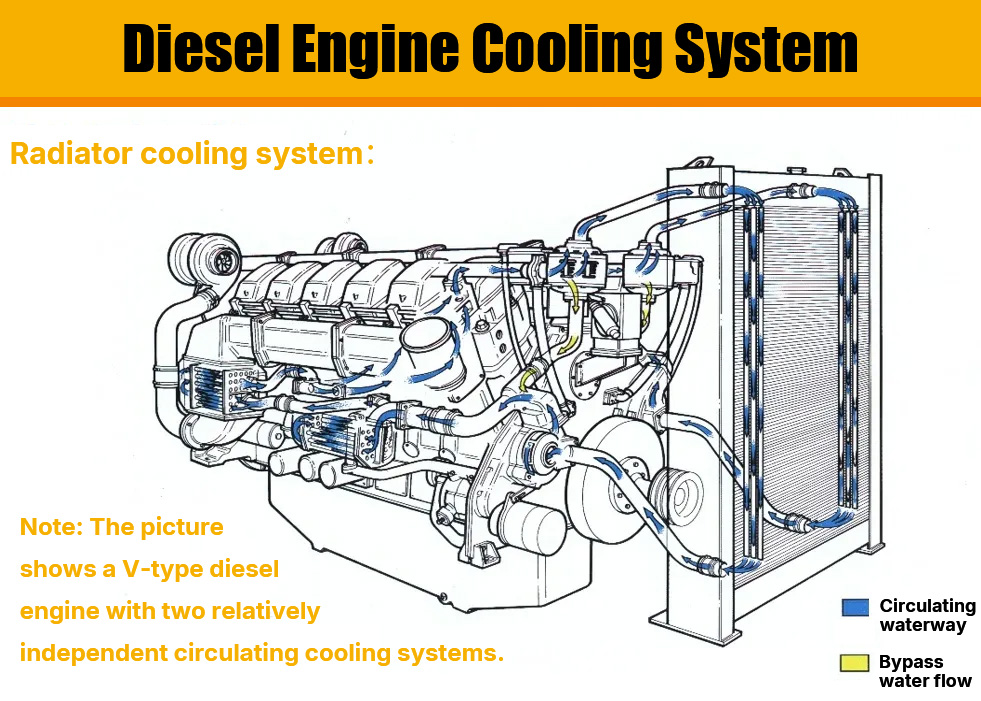

Cooling system:

The cooling principle of diesel engine is the circulating flow of coolant in the body to achieve the effect of cooling down the unit, there are two kinds of cooling devices in general:

One is the radiator cooling system: most diesel engines use the first type of cooling system, through the fan driven by the diesel engine to blow cold air into the radiator to achieve a cooling effect.

Another is the heat exchanger cooling system: such as when the unit is installed in an undesirable working environment, such as underground storage. In this environment of the generator room, its air intake effect will be affected, so we will use the heat exchanger cooling system.

The heat generated by the diesel engine is cooled by the cooling water in the heat exchanger, and the cooling water that has been exchanged by the pump is brought to the external water tower or tank for cooling, and the cooled cooling water flows back to the heat exchanger so that the cooling cycle can be completed.

Cooling water requirements:

Soft water such as rainwater or tap water should be used instead of seawater or well water hard water. Appropriate antifreeze (for cold areas) or rust inhibitor should be added to the cooling water at the same time.

DG Diesel Generators Engines and alternators

Kotech KGS seires diesel generator sets feature robust engines and alternators, delivering strong power, high torque, quick start capability, and easy maintenance.