Hydropower stands as a testament to mankind’s ability to harness nature’s forces for energy generation. Since its inception, the journey of hydropower has been marked by remarkable milestones, driven by technological advancements that have shaped its course. One such crucial innovation is the integration and evolution of air compressors within hydropower projects. In this article, we embark on a journey through time and technology, unraveling the historical significance and transformative role of air compressors in optimizing hydropower generation.

Hydropower History Unveiled

The origins of hydropower date back to ancient civilizations, where waterwheels harnessed the kinetic energy of flowing water to perform mechanical tasks. Over the centuries, this concept evolved, leading to the construction of the first hydroelectric power plants in the late 19th century. These milestones laid the foundation for the modern hydropower industry we know today. Among the key technological advancements, the introduction of air compressors revolutionized the efficiency and effectiveness of hydropower plants, enabling them to operate more reliably and productively.

(Photo: First hydroelectric power plant at the end of the 19th century)

Navigating the Hydroelectric Process

The journey of water from its source to becoming a powerhouse of energy is a meticulously orchestrated process. It begins with the controlled release of water from reservoirs, often guided by dams and gates. This water then flows through turbines, driving generators that convert mechanical energy into electrical power. In this intricate process, air compressors play a pivotal role. By providing compressed air for essential operations such as valve control, cooling systems, and maintenance, air compressors contribute significantly to optimizing power generation and ensuring the seamless operation of hydroelectric stations.

Diverse Air Compressor Types in Hydro Projects

The heart of efficient air compression lies in the types of compressors employed in hydro projects. Positive displacement compressors, including reciprocating and rotary screw compressors, offer steady and controlled air output. On the other hand, dynamic compressors, encompassing centrifugal and axial compressors, excel in delivering high volumes of air at variable pressures. The choice between these types hinges on factors such as efficiency, reliability, and maintenance requirements. An informed selection ensures the harmony of air compression with the specific demands of each hydropower project.

Maintaining and Fine-tuning Air Compressors

Just as a symphony requires constant tuning to produce harmonious melodies, air compressors demand meticulous maintenance for optimal performance. Regular upkeep, including routine checks, lubrication, and monitoring of critical components, ensures the longevity and efficiency of air compressors. Swift troubleshooting techniques and strategies for identifying and rectifying common compressor issues become invaluable tools in sustaining seamless operations. This emphasis on maintenance underscores the critical link between well-preserved air compressors and the reliable, high-efficiency output of hydropower stations.

Triumphs in Hydro: Case Studies in Kotech Air Compressor Excellence

Real-world success stories provide a testament to the transformative impact of air compressors in hydropower projects. Through an in-depth analysis of select case studies, we delve into the intricacies of project design, efficiency measures, and environmental considerations. These case studies serve as beacons of inspiration, offering valuable insights and lessons learned that can guide future hydropower endeavors towards achieving greater efficiency, reliability, and environmental sustainability.

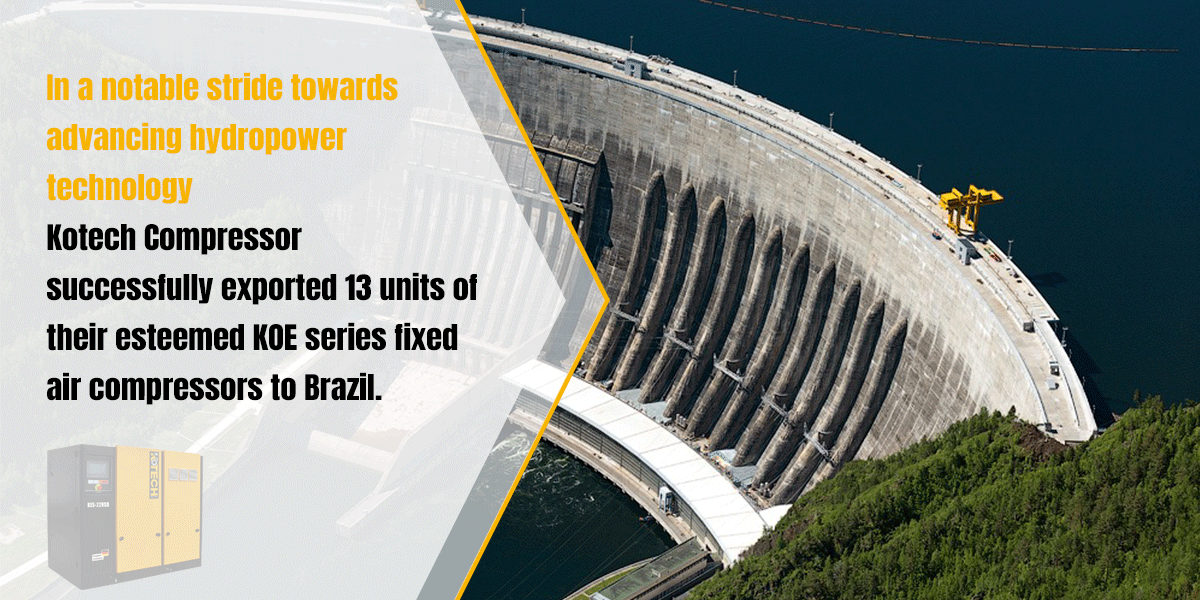

In a notable stride towards advancing hydropower technology, Kotech Compressor, a leading innovator in air compression solutions, successfully exported 13 units of their esteemed KOE series fixed air compressors to Brazil. This achievement underscores the crucial role that air compressor technology plays in optimizing hydropower projects.

The Brazilian hydropower landscape, renowned for its vast water resources and untapped potential, found an ideal partner in Kotech Compressor. The KOE series, known for its reliability and efficiency, seamlessly integrated with the intricacies of Brazilian hydroelectric projects, contributing to enhanced power generation and operational excellence.

Each unit of the KOE series fixed air compressor was meticulously engineered to align with the unique requirements of Brazilian hydropower stations. The compressors proved instrumental in tasks such as valve control, cooling systems, and maintenance procedures. This not only streamlined operations but also significantly contributed to elevating the efficiency and reliability of the hydropower facilities.

The Kotech Compressor success story in Brazil serves as a compelling case study, illustrating the transformative impact of advanced air compression technology on hydropower initiatives.

As the global quest for efficient and eco-friendly energy sources intensifies, the partnership between Kotech Compressor and Brazilian hydropower projects serves as an inspirational beacon, guiding the way towards harnessing the full potential of hydropower and emphasizing the integral role of air compressors in this journey of progress.

Conclusion

As we traverse the historical narrative of hydropower’s evolution and the consequential role of air compressors, a resounding theme emerges – the symbiotic relationship between technological innovation and the efficient harnessing of natural resources. The integration of air compressors within the realm of hydropower has propelled this renewable energy source to new heights of reliability and efficiency, providing a blueprint for sustainable energy generation for generations to come.