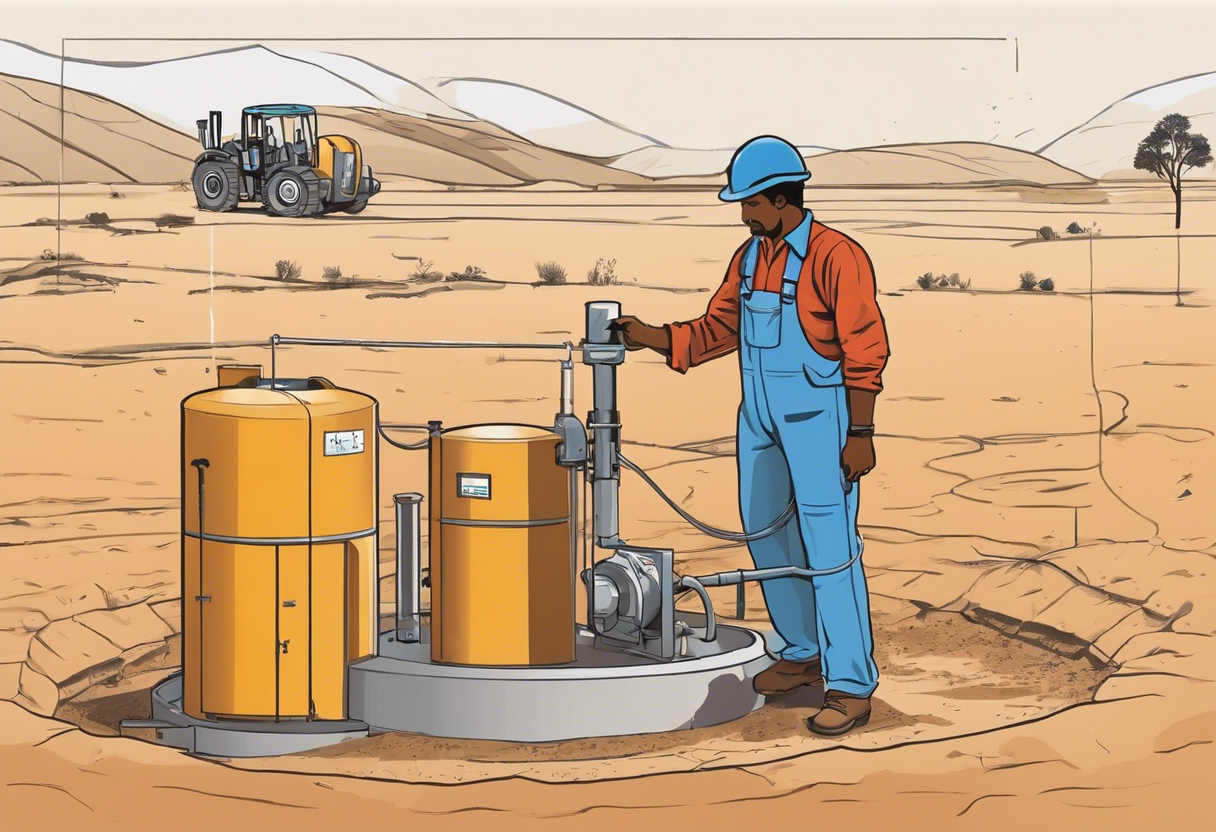

In the realm of borewell operations, the choice of equipment plays a pivotal role in determining efficiency and productivity. One innovation that has proven to be a game-changer is the use of air compressors. Specifically engineered for borewell applications, these compressors offer a versatile solution to the challenges faced in drilling and extraction processes.

Understanding Borewell Applications

Borewell applications involve drilling deep into the ground to extract water, minerals, or perform other essential functions. These operations require powerful machinery that can generate high-pressure air to drive drilling equipment and remove debris. An air compressor plays a pivotal role in providing the necessary air power for effective drilling.

Factors to Consider when Selecting an Air Compressor

Selecting the right air compressor for borewell applications requires careful consideration. Below are some factors to keep in mind during the selection process:

- Power and Pressure Requirements: Determine the power and pressure requirements of your drilling equipment. Choosing an air compressor with the appropriate horsepower and pressure capacity is crucial for successful borewell operations.

- Portability: Consider the portability of the air compressor. Borewell applications often involve moving the equipment to various locations. Opting for a portable air compressor allows for easy transportation and flexibility on the job site.

- Duty Cycle: Assess the duty cycle of the air compressor, which refers to its ability to operate continuously without overheating. Borewell applications may involve long drilling sessions, so selecting an air compressor with a high duty cycle ensures uninterrupted performance.

- Reliability and Durability: Borewell environments can be harsh and demanding. Look for an air compressor that is built to withstand rugged conditions and has a reputation for reliability. This ensures minimal downtime and a longer lifespan for the equipment.

- Fuel Source: Consider the available fuel options for the air compressor. Depending on the site conditions and availability, choose between electric, diesel, or gasoline-powered compressors. Each has its own advantages and considerations that should align with your specific requirements.

Types of Air Compressors Suitable for Borewell Applications

There are various types of air compressors available on the market, but not all are suitable for borewell applications. Here are some commonly used air compressors for this specific purpose:

- Diesel Portable Air Compressors: KOTECH-KDP Series compressor is ideal for a variety of industrial and commercial uses. Boasting high capacity and reliable performance, this durable compressor ensures long-lasting use.

- Rotary Screw Air Compressors: Rotary screw compressors are known for their high capacity and energy efficiency. These compressors utilize dual rotors to compress air and are ideal for heavy-duty drilling operations.

- Centrifugal Air Compressors: Centrifugal air compressors are suitable for larger borewell operations. These compressors work by dynamically accelerating air and can deliver high volumes of compressed air efficiently.

Key Features to Look for in an Air Compressor

When selecting an air compressor for borewell applications, consider the following key features:

- Pressure Rating: Ensure the air compressor can meet the required pressure rating for your drilling equipment. It should have the capacity to deliver the necessary pressure consistently.

- Airflow Capacity: Look for an air compressor with an adequate airflow capacity to drive your drilling equipment effectively. Insufficient airflow can lead to inefficiency and delays in operations.

- Safety Features: Prioritize safety when selecting an air compressor. Features such as automatic shut-off valves, pressure relief valves, and temperature sensors help prevent accidents and protect the equipment.

- Control System: An advanced control system allows for convenient operation and monitoring of the air compressor. Look for features like digital displays, remote control capabilities, and pressure adjustment options for optimal efficiency.

- Noise Level: Borewell applications often involve working in noise-sensitive environments. Opt for an air compressor with low noise emissions to maintain a quieter work atmosphere and comply with noise regulations.

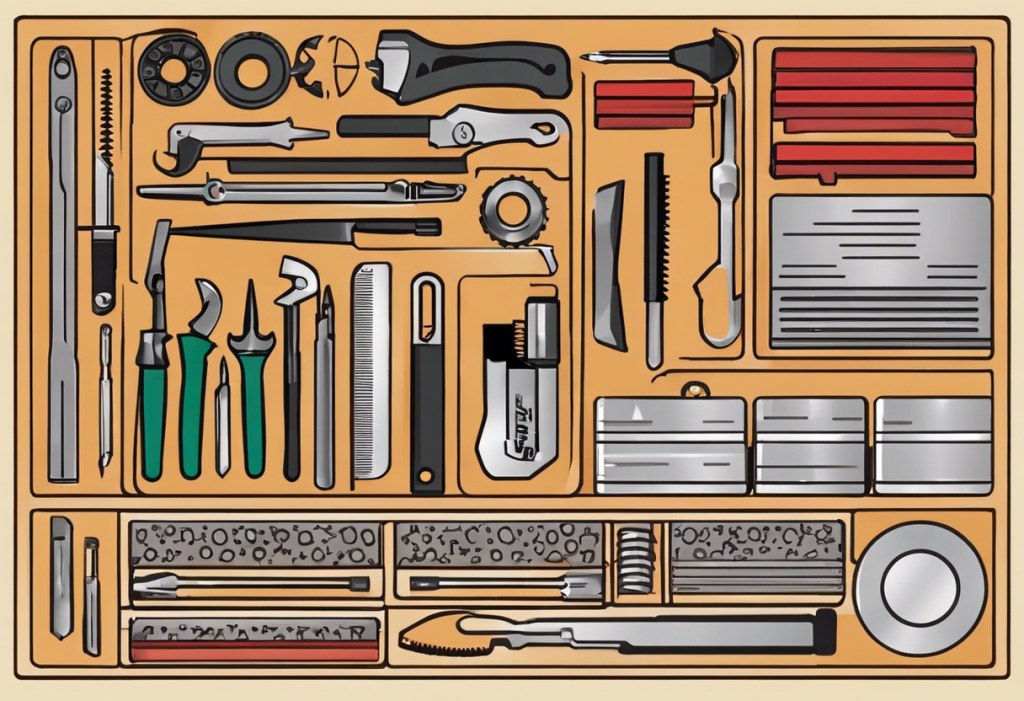

Maintenance Tips for Optimal Performance

To ensure optimal performance and longevity of the air compressor, follow these maintenance tips:

- Regular Inspection: Conduct routine inspections of the compressor for any signs of wear and tear. Check for leaks, loose connections, and other issues that may affect its performance.

- Oil Changes: Follow the manufacturer’s guidelines for regular oil changes. Clean and fresh oil helps lubricate the compressor’s components and prevents excessive friction and heat buildup.

- Air Filter Cleaning/Replacement: Keep the air filter clean or replace it as recommended to prevent dust and debris from clogging the system. A clogged air filter can reduce airflow and strain the compressor’s motor.

- Drain Condensate: Regularly drain any condensate that accumulates in the air compressor’s tank. Excess moisture can damage the internal components and affect its efficiency.

- Scheduled Servicing: Schedule periodic servicing and maintenance with a qualified technician. They can inspect and address any potential issues and ensure the compressor operates at its best.

By following these maintenance practices, you can maximize the lifespan and performance of your air compressor for borewell applications.

In conclusion, selecting the right air compressor for borewell applications is vital for successful and efficient drilling operations. Consider factors such as power requirements, portability, and reliability when choosing an air compressor. Types of compressors suitable for borewell applications include reciprocating, rotary screw, and centrifugal compressors. Additionally, prioritize key features like pressure rating, airflow capacity, safety features, control system, and noise level. Maintain the compressor regularly to optimize its performance and ensure a longer lifespan. With the right air compressor, you can enhance productivity and achieve excellent results in your borewell applications.

Discover the power of Kotech Compressor’s products, designed to meet diverse needs. From our best portable air compressors ideal for various applications, including mining, to the specialized efficiency of our KDP series air compressors for borewell operations.