Energy Efficient Air Compressor: Strategies and Applications

TABLE OF CONTENTS

On April 16, 2021, General Secretary Xi Jinping pointed out during a video summit with the leaders of France and Germany that China will strive to achieve peak carbon dioxide emissions by 2030 and carbon neutrality by 2060, which means that China, as the world’s largest developing country, will accomplish the highest rate of reduction in the intensity of carbon emissions in the world, and achieve the transition from peak carbon to carbon neutrality in the shortest period of time in the history of the world. This will undoubtedly be a hard battle.

In this context, the problem of high energy consumption of air compressor system is gradually highlighted, and new requirements have been put forward for energy-saving technology of air compressor.

Air compressor system energy consumption problems are mainly reflected in:

1. high energy consumption of air compressor equipment;

2. serious leakage of the host;

3. large pressure loss (eg: gas pipeline pressure loss, etc.);

4. Irrational layout;

5. lack of dynamic regulation;

6. lack of energy recovery and utilization programs.

Three ways of energy saving air compressor

We have been talking about energy saving, how to save energy? There are three main ways: first, to improve the efficiency of electricity utilization; the second is high-efficiency drives; the third is to reduce the host specific power.

Pathway 1: improve power utilization efficiency

Strategy 1: reduce reactive power loss

We do energy saving, we must do every link to the end of the section, do not ignore the available opportunities.do not ignore the available opportunities.As we all know, the West-East power transmission is the use of high-voltage transmission technology, why not use low voltage? Why not use low voltage?

Because low voltage transmission losses are too great. So one of the strategies to improve power utilization is to reduce reactive power loss, the solution is to remove the transformer to high-voltage motor. After all, 10kV to 380V transformer reactive power loss is still relatively serious.

Of course, for small power compressor, not recommended to use 6kV or 10kV or more voltage, recommended for use in the 200kW power band.

Strategy 2: Reduce line loss

Solution: High voltage transmission

Cables used to transmit electricity also consume electricity. When an air compressor is running, we measure the temperature of the cable and find that it is hot. Where does the heat come from? It must be converted from electricity. However, due to the small transmission current of the high voltage machine, the cable basically does not heat up.

The strategy of improving the efficiency of electricity utilization is to improve the efficiency of electricity utilization by using high voltage electricity.

Path 2: High efficiency drive

Usually the energy-saving way of motor is frequency conversion, so the trend of the air compressor industry in the past decade is to use permanent magnet frequency conversion technology to improve the energy efficiency of the compressor.

So the trend of the air compressor industry in the past decade is to use permanent magnet frequency conversion technology to improve the energy efficiency of the compressor. Therefore, the core of route two is to use permanent magnet frequency conversion technology to achieve energy saving.

Path 3: Reduce the host specific power

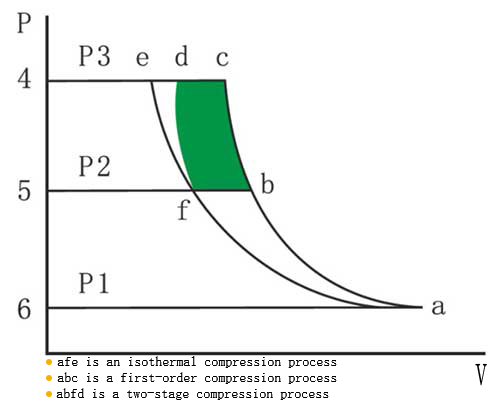

According to Kotech observations at the Shanghai International Compressor and Equipment Exhibition, there are still many single-stage compression machines. Single-stage compression is less efficient, so we have to improve the compression efficiency, one is to reduce the leakage between teeth, and the other is to use as close to isothermal compression as possible to improve the compression efficiency.Therefore, the use of two-stage compression technology is necessary.

In summary, these three ways correspond to the three energy-saving technologies of the air compressor industry, respectively, high pressure, permanent magnet frequency conversion and two-stage compression, so a product called high pressure permanent magnet frequency conversion.

Energy Efficient Air Compressor

Kotech’s KFU Series oil-injected screw air compressor is the perfect choice for your business needs. This variable-speed air compressor is equipped with a specially designed drive that controls and adjusts the operating speed, delivering more constant pressure and protecting against power surges.

Analysis of the three main ways to save energy

1.Why use high voltage electricity?

Load loss: transformer loss per day = (no load loss + load loss × square of load rate) × 24

No-load loss: When the secondary winding of the transformer is open and the rated voltage of the sinusoidal waveform is applied to the primary winding, the active power consumed is called no-load loss.

How big is the difference between high voltage and low voltage?Let’s assume a data, using a common 800kVA transformer as an example.The customer may be a 2000kVA, 3150kVA, or even a larger transformer, let’s see how much the loss of the 800kVA transformer is.

Taking the loss of 800kVA dry transformer as an example, the load rate of the transformer is 50%, then the daily power consumption is:

800kVA dry-type power transformer no-load loss has 1160W, a month is about 24 × 30 × 1.16 = 835.2 degrees of electricity.

800kVA dry-type power transformer load loss has 5220W, a month about 24 × 30 × 5.22 = 3758.4 degrees of electricity.

No-load loss is an invariant loss, independent of the current passed, but related to the voltage borne by the element.

No-load loss is only to power the transformer, there is no load behind, at this time only the transformer power consumption.Its no-load loss is about 1160 watts, and it can consume more than 800 kilowatts of electricity a month, which is wasted.At the time of load, the loss of the transformer can reach more than 5000 watts, and more than 3700 degrees of electricity will be wasted in a month.

Will the high voltage machine have this kind of loss? There will be. For example, in its superior transformer, such as 35kV, 110kV, 220kV to 10kV when there is also loss. But the loss is less 10kV to 380V this part, so there will be less loss of some of the power.

2. Why use permanent magnet synchronous motors?

Why do permanent magnet motors save energy? Ordinary asynchronous motor stator coil energization produces rotating magnetic field, magnetic field cuts rotor, rotor produces alternating current, the current produces magnetic field, stator magnetic field drives rotor magnetic field rotation.In this process, the rotor consumes electricity because the rotor itself is not magnetic, and its magnetic field energy is obtained by absorbing electricity from the grid.

The permanent magnet inverter synchronous motor, because the rotor permanent magnet with its own magnetic field, when the motor stator coil is energized to generate a rotating magnetic field, the stator rotating magnetic field can directly drive the rotor magnetic field rotation, which eliminates the need for an excitation link.

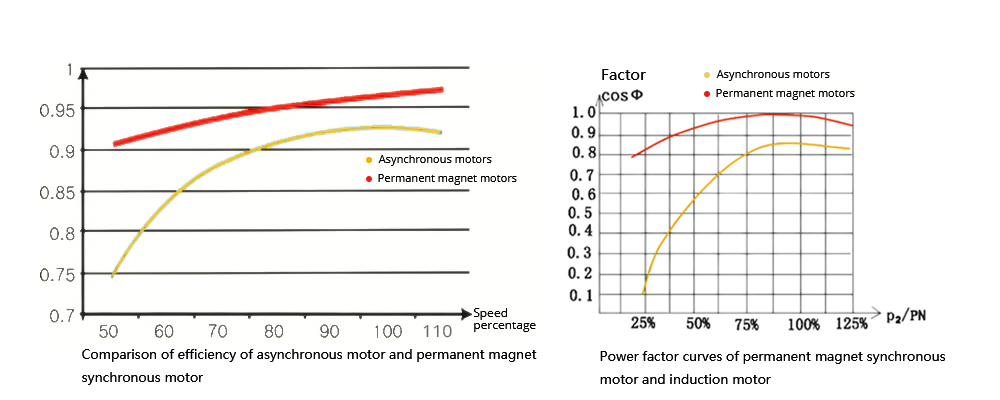

The efficiency and power factor of permanent magnet motors do not change much with the load rate and speed, while the efficiency and power factor of ordinary asynchronous motor vary greatly with the load rate and speed.

3. Energy-saving principle of frequency conversion control

The efficiency of asynchronous motor will be very low at low load, so permanent magnet motor is more suitable for regulation. As can be seen from the efficiency comparison chart for different types of motors, the power factor varies a lot.

4. Constant pressure gas supply

Everyone understands the principle of constant pressure gas supply, but there are some differences when we do it. For example: the customer wants 8kgf model, does not mean that the customer needs 8kgf constant pressure gas supply, if the compressor is supplied with 8kgf constant pressure gas, it is a waste of energy. Commissioning is to adjust the compressor to the customer’s best use of the state, rather than the compressor into the factory state. Therefore, debugging this link is very important, you need to adjust the pressure to the customer’s real demand for pressure, that is, the best working condition of the air compressor.

The pressure of the air compressor does not need to be adjusted very high, because it is too high for customers to use, as long as it meets the needs of customers, it saves the original process of adding and unloading.

The application of energy-saving technology in kotech compressor products

1. Explosion-proof permanent magnet frequency conversion technology used in coal mines with frequency conversion compressor:

① Small impact, reliable operation;

② Frequency conversion control to reduce power waste;

③ Smaller volume, more suitable for underground space.

2. High voltage permanent magnet frequency conversion technology:

① Save low voltage transformer, reduce transformer transmission loss, high power utilization rate;

② Built-in inverter system real-time adjustment speed, reduce power loss caused by gas fluctuation.

3. Permanent magnet frequency conversion dry oil-free screw air compressor:

① Rotor super coating to prevent leakage due to wear and tear, to ensure stable and long-lasting performance;

② Reliable cooling system effectively reduces the power consumption of the compressor, improve the efficiency of the host;

③ Frequency control, a wider range of adaptability to the volume of gas.

4. Permanent magnet high-speed frequency conversion centrifugal compressor:

① Unique processing technology to manufacture a more efficient primary molding impeller to improve compression efficiency;

② Using ternary flow impeller design to make higher gas flow efficiency.

5. Permanent magnet high-speed frequency conversion centrifugal compressor:

① Unique processing technology to manufacture a more efficient primary molding impeller to improve compression efficiency;

② Using ternary flow impeller design to make higher gas flow efficiency.

③ Equipped with high-speed permanent magnet synchronous motors, with the minimum energy consumption to achieve better results.

Jump to your selection➷

How does the air compressor work?

What does 2 Stage Air Compressor Mean?

How do Rotary Screw Air Compressors Work Diagram?

Control Valve Types and Applications