Mobile Diesel Driven Air Compressor for Sale

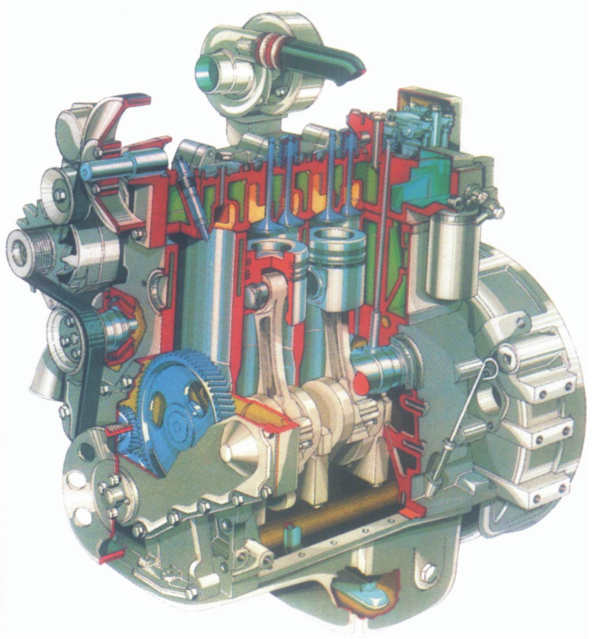

Diesel Engine Overview

A diesel engine is an internal combustion engine that uses diesel as fuel. Diesel engines are compression ignition engines, and they are often called Diesel engines after the main inventor Diesel.

When the diesel engine is working, the air sucked into the diesel engine cylinder is compressed to a high degree due to the movement of the piston, reaching a high temperature of 500 to 700℃. Then the fuel is sprayed into the high-temperature air in the form of mist, and mixed with the high-temperature air to form a combustible mixture, which will automatically ignite and burn.

Rudolf Diesel(wikipedia), a French-born German engineer, successfully developed a practical 4-stroke diesel engine in 1897.In 1905, the first marine two-stroke diesel engine was made.

Basic Terminology used for a Engine

1.TDC(Top Dead Center)

When the piston makes reciprocating linear motion in the cylinder, when the piston moves upward to the highest position, that is, the extreme position where the top of the piston is farthest from the center of rotation of the crankshaft, it is called top dead center (TDC).

2.BDC(Bottom Dead Center)

When the piston makes reciprocating linear motion in the cylinder, when the piston moves downward to the lowest position, that is, the limit position closest to the top of the piston from the center of rotation of the crankshaft, it is called bottom dead center (BDC).

3.Piston stroke

The distance the piston moves from one dead center to the other, that is, the distance between the upper and lower dead centers is called the piston stroke. Generally represented by S, corresponding to one piston stroke, the crankshaft rotates 180°

4.Crankshaft radius

The distance between the crankshaft rotation center and the crank pin center is called the crank radius, generally represented by R. Usually the piston stroke is twice the crank radius, that is, S =2R.

5.Cylinder working volume

The volume swept by the piston from one dead center to another dead center is called the cylinder working volume.

Generally expressed as Vh:

6.Combustion chamber volume

When the piston is at the up-to point, the volume Vc between the top of the piston and the cylinder head

7.Engine capacity

The sum of the working volumes of each cylinder of a multi-cylinder engine is called engine capacity.

8.Compression ratio

Compression ratio is a very important concept in engines. Compression ratio represents the degree of compression of gas. It is the ratio of the volume before gas compression to the volume after gas compression, that is, the ratio of the total cylinder volume to the combustion chamber volume. called compression ratio. Generally expressed by ε

9.Work cycl

Each working cycle includes the processes of air intake, compression, power generation and exhaust. That is, completing the four processes of air intake, compression, power generation and exhaust is called a working cycle.

Diesel Engine Classification Introduction

There are many types of diesel engines.

① According to the working cycle, it can be divided into 4-stroke and 2-stroke diesel engines.

② According to the cooling method, it can be divided into water-cooled and air-cooled diesel engines.

③ According to the intake method, it can be divided into supercharged and non-supercharged (naturally aspirated) diesel engines.

④ According to the speed, it can be divided into high speed (more than 1,000 rpm), medium speed (300 ~ 1,000 rpm) and low speed (less than 300 rpm) diesel engines.

⑤ According to the combustion chamber, it can be divided into direct injection, vortex chamber and pre-combustion chamber diesel engines.

⑥ According to the gas pressure action mode, it can be divided into single-acting, double-acting and opposed piston diesel engines.

⑦ According to the number of cylinders, it can be divided into single-cylinder and multi-cylinder diesel engines.

⑧ According to the purpose, it can be divided into marine diesel engines, locomotive diesel engines, vehicle diesel engines, agricultural machinery diesel engines, engineering machinery diesel engines, power generation diesel engines, and stationary power diesel engines.

⑨ According to the oil supply method, it can be divided into mechanical high-pressure oil pump oil supply and high-pressure common rail electronically controlled injection oil supply.

⑩ According to the cylinder arrangement, it can be divided into in-line and V-shaped arrangement, horizontally opposed arrangement, W-shaped arrangement, star arrangement, etc.

(Diese engine rotavator farm machine power tiller – eagle power. (2024). From eaglepowermachine.com

Diesel Engine. (2024). From betweeneastwest.com/en/blog-detail/Diesel-Engine)

Working principle of mobile diesel engine

The operation of a diesel engine is accomplished through four processes: intake, compression, combustion expansion, and exhaust. These four processes constitute a working cycle.

(Working principle of mobile diesel engine)

Working principle of mobile diesel engine

Are you looking for a reliable and efficient power source for your textile industry? Kotech dealers are experienced in finding the perfect air compressor for your needs.

Contact your local Kotech dealer today and discover how an air compressor can increase your productivity and safety.

How to Choose the Right Diesel Mobile Compressor

Application:

Mobile diesel screw air compressors are mainly used in the drilling and blasting market, open-pit mines, water conservancy and hydropower construction, coal bed methane market, municipal special air compressors, oil pipeline pressure test air compressors, oil/gas pipeline purging, sandblasting and rust removal, Large-diameter embedded rock foundation piles, oil and gas wells, coalbed methane wells, mining area gas drainage wells, water wells, geothermal wells, geothermal air-conditioning wells, geological exploration holes, large-diameter reverse circulation holes, foundation piles and all-round solutions and provide oil and natural gas , coal bed methane, mining, municipal construction, geological exploration, pipeline construction, water well construction and other industries.

Application Environment:

Choose between stationary or mobile air compressors based on the application environment. For example, mining operations may benefit from mobile air compressors. Therefore, we recommend kotech KDP Series products.(click here) Consider factors such as the size of the main equipment room, natural ventilation, noise isolation, equipment temperature, and wastewater recycling.

Energy Efficiency Labeling:

Considering a usage period of twenty years, the purchase cost of the air compressor constitutes approximately 5-10%, maintenance costs about 5-10%, and power consumption costs around 80-90%. The editor of Kotech provides you with 8 Tips for Air Compressor Energy Efficiency. One of the ways to save energy is to adjust unreasonable air consumption behavior. Therefore, prioritize energy efficiency by selecting compressors with higher efficiency ratings, as energy savings translate to cost savings!

Suitable ambient temperature for mobile diesel air compressor:

The suitable operating temperature for mobile diesel air compressor is between 5℃-40℃. When the ambient temperature exceeds this range, the performance of the mobile diesel air compressor will be affected.

In a low-temperature environment, the startup of the diesel engine will be affected, and the temperature of the cylinder will be too low, affecting the compression efficiency of the gas; in a high-temperature environment, the cooling effect of the diesel engine may be insufficient, affecting the service life of the mobile diesel air compressor.

Air Compressor Displacement: (Air Delivery)

Displacement refers to the volume of gas discharged by the air compressor per unit of time under the required exhaust pressure.

Choosing an appropriate displacement is crucial to avoid excessive energy wastage or insufficient performance. Select the displacement based on specific operational needs.

Air Compressor Working Pressure:

Imagine moving a small ball on the ground. Using compressed air at 75 psi may not be sufficient, while 100 psi can move the ball the desired distance. Determining the right supply pressure is of utmost importance.

At Kotech Compressor, we are also proud to offer high-quality portable air compressor & parts.

Why choose our portable air compressors?

Portable Air Compressor Maintenance and Care

-

Strict Training for Operators:

Operators must undergo rigorous training and obtain an operational certificate through examination before being authorized to operate. Operators should be familiar with the performance and structure of the equipment and adhere to safety and shift handover procedures.

-

Implementation of Protective Measures:

Generator sets should have facilities in place for rain, wind, and fire protection. For stationary generator sets, the working ground must remain dry, the frame should be securely padded, and insulation mats should be used. The four-wheel tires of mobile generator sets must meet specified pressure requirements and be kept balanced. Install protective devices for instrument protection, grounding wire joints, cables, and pipeline connections.

-

Pre-Startup Checks:

Before starting, check whether the generator and exciter or excitation regulator are functioning properly. Disconnect all power supply circuit breakers, inspect each phase fuse for any open circuits, and prohibit starting the generator under load conditions (except for unattended automatic standby generators).

-

Voltage Considerations:

Once the diesel engine reaches the rated speed, gradually decrease the resistance of the field rheostat for generators with auxiliary exciters to increase the voltage slightly above the rated value. If the resistance of the rheostat is zero, there is no voltage; adding a small load will establish pressure.

-

Shutdown Considerations:

Before shutting down the generator, gradually reduce the load. Once the load is zero, disconnect the main switch and excitation switch, set the field resistance to the maximum position, and stop the diesel engine. After winter shutdowns, drain the cooling water from the radiator (excluding those filled with antifreeze) to prevent unsafe incidents such as diesel engine freezing.

Click to view examples: Start-Stop Precautions for KDP Series Mobile Air Compressors | Portable Air Compressor Knowledge

-

Routine Cleaning and Maintenance:

- Keep the generator casing and its surroundings clean on a daily basis. In any situation, avoid the entry of dust, water droplets, metal debris, or other foreign objects and maintain good ventilation conditions.

- After work, inspect and clean the equipment, perform routine maintenance to ensure neatness, cleanliness, lubrication, and safety.

Find Portable Air Compressors at Kotech Compressor

For two decades, Kotech has been the go-to for reliable compressors, offering the ultimate in top-quality performance. Whether for business or Industry use, you can trust Kotech to have the best all-around compressor for your needs.

To order a Kotech compressor system, please contact us.

Or you want to become our distributor, you can also contact us to become a Kotech compressor distributor.

Kotech has set up the KDP series 24/7 strategic partnership with High Performance Industry after signing of memorandum in the projects of mobile diesel air compressors.

Good performance and operating of the compressors results lay a solid foundation for our cooperation

These successively delivered machines have drawn a successful start for our brand to go overseas