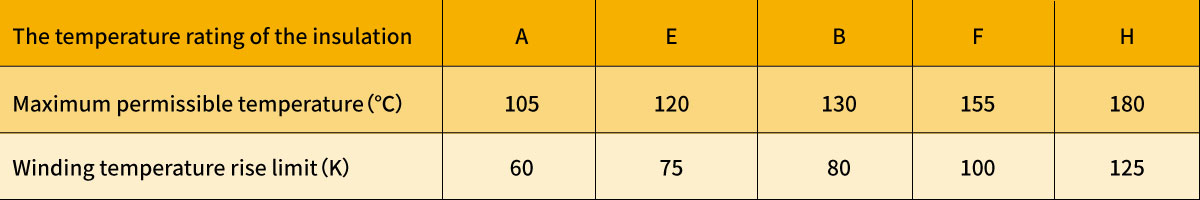

Generally speaking, if the motor insulation level is class A and the ambient temperature is 40℃, then the motor shell temperature should be less than 60℃.

Temperature limits for each part of the motor

1、The temperature rise of the core in contact with the winding (thermometer method) should not exceed the limit of temperature rise of the winding insulation in contact (resistance method), i.e. 60℃ for class A, 75℃ for class E, 80℃ for class B, 100℃ for class F, 125℃ for class H.

2、Rolling bearing temperature should not exceed 95 ℃, sliding bearing temperature should not exceed 80 ℃. Because the temperature is too high will make the oil quality change and destroy the oil film.

3、The casing temperature in practice tends to be not hot.

4、The squirrel cage rotor surface stray loss is very high, the temperature is high, generally to not endanger the neighbouring insulation as a limit. Can be pre-brushed with non-reversible colour paint to estimate.

Air compressor overheating causes motor temperature and temperature rise

Measure the degree of heating of the motor is to use “temperature rise” rather than “temperature”, when the “temperature rise” suddenly increased or exceeded the maximum operating temperature, indicating that the motor has failed. Some basic concepts are discussed below.

The insulation class of insulation materials

Insulating materials are divided into Y, A, E, B, F, H, C7 grades according to the heat-resistant ability, the ultimate working temperature were 90 ℃, 105 ℃, 120 ℃, 130 ℃, 155 ℃, 180 ℃, and 180 ℃ or more. Performance reference temperature (℃) A80 E95 B100 F120 H145

Insulation materials can be classified into 7 grades according to thermal stability as follows:

- Y grade, 90 degrees, cotton

- A grade, 105 degrees

- E grade, 120 degrees

- Grade B, 130 degrees, mica

- Grade F, 155 degrees, epoxy resin

- Grade H, 180 degrees, silicone rubber

- C class, 180 degrees above

The commonly used Class B motors often have Class F internal insulation, while the copper wire may use Class H or even higher to improve its quality.

Generally in order to improve the service life, often provide for high-level insulation requirements, a lower level to assess. For example, the common F-level insulation of the oil pump motor does B-level to assess, that is, its temperature rise can not exceed 120 degrees (leaving 10 degrees as a margin to avoid process instability caused by individual motor temperature rise over the poor).

The so-called limit operating temperature of the insulation material refers to the motor in the design of the expected life and operation of the winding insulation in the hottest temperature. According to experience, class A materials at 105 ℃, and class B materials at 130 ℃ in the case of life up to 10 years, but in practice the ambient temperature and temperature rise will not reach the design value for a long time, so the general life expectancy of 15 to 20 years.

If the operating temperature is for a long time more than the material’s limiting working temperature, the aging of the insulation is aggravated, and the life is greatly reduced. So the motor in operation, temperature is one of the main factors of life.

The insulation class of the motor refers to the heat-resistant class of the insulating material used in it, which is divided into classes A, E, B, F, and H. The insulation class of the motor is the heat-resistant class of the insulating material used in it. Allowable temperature rise is the limit of the motor’s temperature increase compared to the ambient temperature. In electrical equipment such as generators, the insulation material is the weakest link.

Insulating materials are particularly susceptible to accelerated aging and damage due to high temperatures. Different insulating materials have different heat resistance properties, and electrical equipment with different insulating materials have different abilities to withstand high temperatures. For this reason, the maximum operating temperature of electrical equipment is generally specified.

Understanding Optimal Temperature Ranges for air compressor

What are the high-temperature preventive measures for a good air compressor?

Air compressor exhaust temperature is too high and is more common in summer, usually difficult to attract the attention of the operator. Continuous high exhaust temperature will lead to reduced productivity, doubling the wear and tear of the equipment, and shortening its life of the equipment!

Therefore, it is very important to do a good job of air compressor high-temperature preventive measures, so that your air compressor refreshes summer, to protect the normal production of enterprises.

Titanium Spirit compressor for your warm tips, in the prevention of high-temperature failure of air compressors, several aspects need to pay attention to:

1. Environmental temperature

The air compressor’s high temperature is sometimes due to the air compressor room design is not reasonable, ventilation is not smooth, the heat emitted by the air compressor can not be discharged out of the air compressor room, the high-temperature air is inhaled by the air compressor caused by the exhaust temperature is too high, which also causes the frequent occurrence of high-temperature failure of the air compressor.

The operating temperature of the air compressor is best under 30℃~40℃. The high temperature and hot weather in summer are more obvious in factory workshops. Therefore, the ventilation system of the air pressure station room should be improved as much as possible in summer.

An exhaust fan can be added in the air pressure station room, air inlet and exhaust port placed in the wall facing the outdoor open space, the air pressure station room the hot air out, thereby reducing the temperature.

Heat sources with high temperatures should not be placed around the air compressor. If the temperature around the compressor is high, it will cause the temperature of the intake air to be too high, and the oil temperature and exhaust temperature will rise accordingly.

2. Temperature Sensor

Failure of the temperature sensor will cause a false alarm of high-temperature rise and cause a shutdown. Failure of the temperature control valve, the lubricating oil may not pass through the cooler directly into the head, thus the oil temperature can not be reduced, resulting in high temperature.

3. Filter element effect

The air filter element, oil filter element, and oil separator core are clogged. Air filter clogging will cause the air compressor to be overloaded and underload for a long time, resulting in high temperatures; oil filter clogging will reduce the flow rate, and the air compressor will form high temperatures due to incomplete heat discharge. Oil clogging will lead to high internal pressure and high temperature.

4. Cooler

Check whether the cooler is clogged or not, the most direct effect of a clogged cooler is poor heat dissipation performance, making the unit high temperature. Remove debris and clear the clogged cooler to prevent the compressor from overheating.

Check whether the cooling fan and fan motor are normal and whether there is any failure. For water-cooled air compressor can check the inlet water temperature, generally not more than 35 ℃, and water pressure between 0.4 ~ 0.6Mpa. If you can not meet the requirements, you can install a cooling tower.

In short, a small operating negligence may cause our air compressor to high-temperature failure, so in our daily air compressor operation, we must comply with the air compressor operating procedures, correctly let our air compressor for our service, and improve our work efficiency.