What, How and Why | What is a Reciprocating Compressor?

TABLE OF CONTENTS

what is a reciprocating compressor?

Reciprocating compressor definition and basic working principle

When the crankshaft rotation, through the connecting rod drive, the piston will make a reciprocating motion, by the cylinder wall, cylinder head and the piston top surface of the working volume composed of cyclical changes will occur.

Piston from the cylinder head at the beginning of the movement, the working volume of the cylinder gradually increases, at this time, the gas that is along the intake pipe, is pushed open the intake valve and into the cylinder, until the working volume to the maximum until the intake valve closed; piston reverse movement, the working volume in the cylinder shrinks, the gas pressure rises, when the pressure in the cylinder to reach and slightly higher than the exhaust pressure, the exhaust valve opens, the gas out of the cylinder, until the piston Until the piston moves to the limit position, the exhaust valve is closed. When the piston again reverses movement, the above process is repeated.

In short, the crankshaft rotates for a week, the piston reciprocates once, and the cylinder achieves the inlet, compression, and exhaust process, that is, to complete a working cycle.

The ideal working process of the compressor is:

① Compressor no clearance volume;

② Suction and discharge process without resistance loss;

③ Suction and discharge process and the outside world without heat exchange;

④ No leakage;

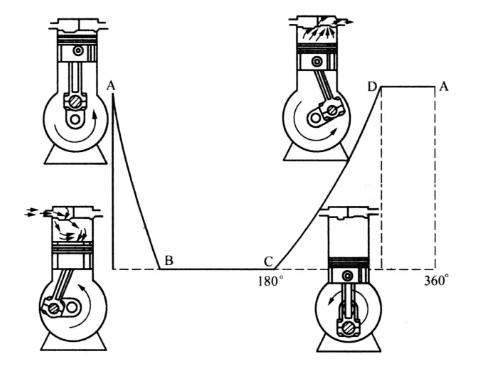

A sketch of the reciprocating motion of a piston in a cylinder:

Figure B-C for the suction process, C-D for the compression process, D-A for the exhaust process, A-B for the gap gas expansion process. Compressor crankshaft rotation of 360 degrees to complete the above four processes, so that low-pressure vapour flow through the suction valve into the cylinder, compressed by the piston into high-pressure vapour and discharged through the exhaust valve.

Reciprocating compressor’s main features:

(1) A wide range of applicable pressure, regardless of the size of the flow, can reach the required pressure;

(2) High thermal efficiency, unit power consumption is low;

(3) Adaptable, that is, a wide range of exhaust, and is not affected by the pressure is high or low, can adapt to a broader range of pressures;

(4) Maintainability;

(5) Low material requirements, more common steel materials, processing is easier, the cost is also cheaper;

(6) Technically mature, the production of a wealth of experience accumulated on the use; (7) the use of reciprocating compressors, the production of a wide range of materials.

(7) The device system is relatively simple;

Disadvantages:

1) The speed is not high, the machine is large and heavy;

2) The structure is complex, wearing parts, and maintenance;

3) The exhaust is not continuous, resulting in airflow pulsation;

4) The operation of a large vibration.

Reciprocating Compressor VS. Rotary Compressor

The rotary compressor mainly consists of an eccentric shaft.

Rotary piston, cylinder, slide composition. The rotary piston is in an eccentric position relative to the cylinder center line. The cylinder bore and rotary piston form a crescent-shaped space between the base circle, and the slide in the spring force under the action of tightly pressing the rotary piston, piston rotation crescent-type space volume gradually for corresponding changes.

The reciprocating air compressor shaft was elbow line, there was no connecting rod mechanism, and the piston was different from the general piston, but in the vertical direction of the lower end of the piston welded to a long round hole in the short tube, so that the cylindrical slider installed in the end of the crankshaft, when the crankshaft for the rotary movement, driven by the slider in the piston at the lower end of the short tube sliding left and right, so that the piston reciprocating movement. Rotary compressor efficiency, easy to hold the shaft and jam cylinder. Reciprocating compressor working time is long. Easy to wear, knock cylinder, dislocation.

Common Applications for Reciprocating Compressors

Reciprocating compressor application Placement.

1 The air compressor should be placed in a well-ventilated place with low humidity, less dust, no dirt, sufficient light, and easy to check and refuel.

2 The casters of the compressor must be at the same level when placing the compressor, otherwise it will cause vibration and even safety accidents.

3 The air compressor must be far away from flammable and explosive materials.

4 For the convenience of operation and maintenance, there should be 0.5-0.8 meters of access around the machine.

Common applications of reciprocating compressors

Depending on the level of pressure required, it can be made into single or multiple stages;

In order to make the machine load balanced, it can be made into single or multi-row.

It is the power source to increase pressure and transport medium in chemical production, and the working medium is quite wide.

Characteristics: wide range of applicable pressure, high compression efficiency, adaptability;

Scope: Reciprocating compressed air applications are very wide, and theoretically can be compressed in any medium of gas, which is widely used in energy storage, pipeline pressure, natural gas, petrochemical, sewage treatment, wind tunnel testing, weapons manufacturing, blowing, diving, and other industries.

Basic Components of a Compressor

Working chamber part (cylinder, seal, piston, valve)

Base part (fuselage, crankshaft, coupling rod, intermediate section cylinder part)

Accessory systems (cooling, lubrication, sealing, regulation, piping)

Driving device (motor)

1、The body

It is the positioning of the compressor base components, by the body, the body and crankcase three parts.

Small machines are sometimes made into one.

2、transmission mechanism

By the clutch, pulley or coupling and other transmission devices, as well as the crankshaft, connecting rod, crosshead and other moving parts.

3、Compression mechanism

By the cylinder, piston assembly, inlet and exhaust valves and other components.

When the piston reciprocates, the work process is completed cyclically (double-acting type is carried out on both sides of the piston at the same time).

4、Accessories

By the circulating oil system, cooling water system, disc device, cooler, buffer, oil and water separator, various pipelines, valves, electrical equipment and its protective devices, safety guards, nets and so on.

Are you looking for a reliable and efficient power source for your industry? Kotech dealers are experienced in finding the perfect air compressor for your needs.

Contact your local Kotech dealer today and discover how an air compressor can increase your productivity and safety.

Reciprocating Compressor Maintenance & Troubleshooting

Reciprocating compressor design principle and its structural characteristics and the complexity of the working conditions, making its wear parts, high failure rate, poor reliability, easy to affect the normal production and operation of the enterprise, and even a failure of the stopping accident will lead to up to ten million yuan of economic losses, so it is very important to enhance the stability of the compressor’s operation and work.

Reciprocating compressor common causes of failure analysis and solution measures:

1. Compressor exhaust volume is not enough exhaust volume is compared with its rated exhaust volume.

To consider.

Failure of the inlet filter dirt clogging, so that the exhaust volume is reduced; the suction pipe is too long, and the pipe diameter is too small, resulting in increased suction resistance that affects the volume of gas.

2. Pressure is not normal, the exhaust pressure is reduced, the compressor discharged under the rated pressure can not meet the flow requirements of the production process, and the exhaust pressure is bound to reduce the exhaust pressure to reduce the phenomenon, the essence is that the amount of exhaust can not meet the requirements of the process.

The main reason for the impact of interstage pressure is not normal valve leakage or piston ring wear and tear leakage, so from these aspects to find the cause of the failure, and targeted measures.

3. The compressor sounds abnormal compressor in the process of operation, if some parts of the defective fault, there will be an abnormal sound, generally speaking, the operator can determine the source of the abnormal sound.

Compressor common fault judgment

Features of Kotech Products

kotech provides a variety of solutions for gas needs, customizes air compressor types for customers, and matches the most suitable air compressor according to the purpose of the air compressor.

1, applicable pressure range. Piston compressors from low pressure to ultra-high pressure are applicable, the highest working pressure used in industry is nearly 350MPa, and the pressure used in the laboratory is even higher.

2, high thermal efficiency, and low power consumption. Because of the different working principle, piston compressor than centrifugal compressor efficiency, unit power consumption is less. The adiabatic efficiency of large piston compressors is more than 75-80%.

3, adaptable. That is, a wider range of exhaust, which is not affected by the pressure level, can adapt to a wider range of pressure. In addition, the density of the gas on the performance of the compressor is not as significant as the speed type, so the same specifications of the compressor, the compressor will be used for compression of different media easier to transform.

4, easy to process low material requirements, low cost. For more common steel materials, processing is easier and cheaper.

5, strong reliability. More mature technology, production, and use of a wealth of experience.

6, modular design. The device system is relatively simple. Wide range of applications.