Twin Screw Compressors For New Petrochemical Processes

With the continuous improvement and enhancement of the production process, as well as the “two-carbon target” requirements for the production of the device to produce furnace steam, flue gas (including a variety of process exhaust) processing requirements are more and more stringent, standardised, and to fully recover the valuable components therein, which contains the maximum latent heat extraction and utilisation.

High-temperature furnace steam, flue gas (temperature above 450 ℃ furnace steam, flue gas for the high-temperature section) and medium-temperature furnace steam, flue gas (temperature between 150 ℃ ~ 450 ℃ defined as medium-temperature section) of the comprehensive management and waste heat reuse, is the production unit and engineering design units are very concerned about the focus. High, medium-temperature section of the furnace steam, flue gas recovery and reuse, has been done very well, which can be improved or improved space is limited.

We have found in recent years in the production of enterprise research, the valuable components of the recovery and latent heat extraction, is the production unit managers have long reached a consensus, has been implicit in the design and implementation of each process, almost needless to say.

In this paper, we focus on the low-temperature section of the furnace steam, flue gas waste heat reuse, and the end of the integrated treatment coupled to a new process model. That is, the use of new processes and emerging energy-saving equipment – twin rotary screw air compressor, integrated into a new process model. We define the flue gas and furnace steam emitted from the process unit or the last emission from the front-end process end as the low-temperature section when the temperature of the flue gas and furnace steam is below the low-pressure 150℃.

The flue gas and furnace steam in the low-temperature section often have these characteristics:

First, the temperature is low, which sometimes entrained water vapour, multi-component process steam molecules are more;

Second, there are entrained fine impurities;

Third, it contains non-condensable gas;

Fourth, the gas pressure is relatively low;

In short, “dust with liquid”, low latent calorific value, complex components, the use of the “tasteless, discarded” situation. Now many companies are using the simplest approach, namely, heat transfer – condensation, low-temperature section of the flue gas, furnace steam and a certain temperature of the medium for heat transfer, simple to use, and then the heat transfer of the gas and then discharged to the back end of the VOC treatment section and then unified treatment, or simply through the condensation of the water wash directly approach.

However, some components in the flue gas and furnace vapour are prone to coking, scarring and other “pipe plugging”, causing blockage and corrosion of the heat exchanger at the back end. If for a small amount of waste heat value reuse, the heat exchanger or pipe clogging, but also in the future to regularly clean cleaning, maintenance work behind the more troublesome, it is better to directly wash the method of cooling and condensation, and finally the flue gas, furnace steam in the components of the whole are dissolved in the water into wastewater, discharged through the pipeline to the wastewater treatment station, which is simpler to deal with instead.

The above situation causes many production units would rather give up the low-temperature section of the flue gas, furnace steam in the waste heat is no longer used, but also do not want to spend manpower and material resources behind the heat exchanger to deal with the pipeline, the “plugging” problem.

How to effectively take out and reuse the latent heat in the furnace steam and flue gas in the low-temperature section, and at the same time coupled with the back-end treatment process, to avoid increasing the difficulty and workload of additional processing at the same time, to achieve the goal of emission reduction for the production unit, reduce consumption and increase efficiency, is an important issue. For this reason, we have been in the actual production and application in the past few years after continuous exploration and improvement, summed up a new process technology route, so as to achieve the above objectives.

Twin screw air compressor is in recent years in the trend of energy saving and emission reduction, research and development and manufacturing and has been in the steam waste heat market began to make a big difference in a new type of steam compressor. The prototype is a twin screw process gas compressor, mainly used in the recovery of low-pressure, low-temperature steam, secondary steam, spent steam, pressurisation and warming of the process, in order to achieve the purpose of reuse instead of fresh steam.

Twin screw air compressor has the following characteristics: first of all, the inlet steam state and components are not sensitive, allowing the steam component is more complex, especially for the process steam is particularly applicable. For example, esterification steam, steam in the “dust with liquid” on the operation of the twin screw air compressor is not affected, there will be no “wheezing, vibration” and so on.

On the contrary, if the steam contains some macromolecular components bonded to the surface of the rotor, the outside of the formation of a layer of cladding instead of reducing the gap between the yin and yang rotor, so that the transfer efficiency is higher. Inlet steam state whether saturated, unsaturated or superheated state, the compressor has no effect on the performance of the compressor; secondly, due to the twin screw air compressor is the principle of volumetric, can achieve high pressure ratio, high temperature difference, so that the steam inlet and outlet temperature difference can be set to a large difference, conducive to the realization of the low-temperature and low-pressure steam reuse. Due to the principle of volumetric structure, so the compressor has the ability to vacuum, so in some negative pressure conditions, can directly replace the vacuum equipment to achieve the ability to vacuum, increase the evaporation; the last point is that the compressor is easy to achieve the regulation of change, according to the inlet gas volume changes to achieve the control of the outlet gas volume. Compressor drive speed can be adjusted according to the changes in the inlet gas volume, adjust the high speed or low speed, the output of the gas volume is also adjusted to minimise drive energy consumption.

Comprehensive twin screw air compressor above several features, by combining the following process with the equipment, to give full play to the maximum characteristics and potential of the twin screw air compressor can be achieved at low temperatures to extract heat.

We through the actual operation, in a high-temperature paint spraying workshop, 350m3/min, 117 ℃ flue gas and 25 tonnes of 90 ℃ hot water for heat exchange, and then flash-compression, can produce 3 kg, 1.45T / h of low-pressure saturated steam, the full set of process power consumption of 117kW, the COP approximation of 5, the ratio of energy consumption is very low. After the transformation has produced very good economic benefits, saving 1.45T of fresh steam per hour for the use of units.

We take the furnace steam and flue gas of the low-temperature section as the first heat source, and then use the existing hot water of the production unit as the medium, and couple the MVR technology with the evaporation and crystallisation process and equipment in the back-end wastewater treatment to form a set of brand-new process technology route, which is implemented as follows:

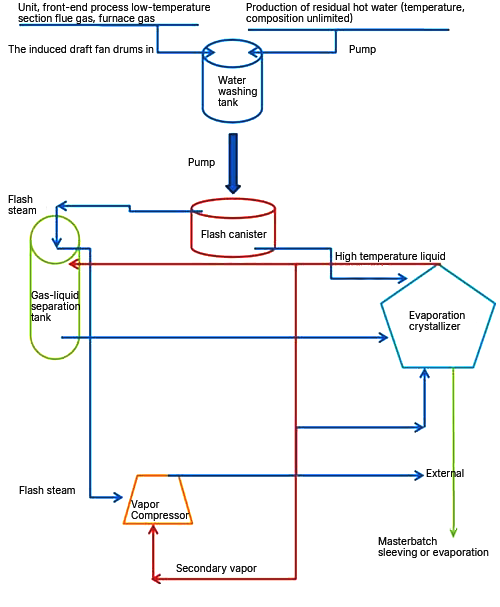

Process flow:

the low-temperature section of the flue gas, furnace steam through the blower, etc. into the water washing tank, while the production of surplus hot water, temperature and components can be unlimited, but to take into account the components of the water and the flue gas, furnace steam in the components whether there is a violent chemical reaction problem. Step 1:If it is a combination of mixing methods that will produce explosions and other major hazards, it should be excluded from the use of such water sources. If the reaction is a strong acid, strong alkali (this reaction is very small possibility in actual production, basically can be ignored), we must consider the selection of tank materials.

General reaction such as weak acid, weak alkali, you can choose corrosion-resistant stainless steel tank, enamel tank or hanging lining rubber tank and other materials, the specific material selection should be based on the actual conditions to determine:

Step 2: high-temperature liquid after washing, at this time the smoke, furnace steam has been fused with hot water, into a certain temperature of the liquid. According to our experience, the temperature of the mixed liquid should be controlled above 95 ℃ best, temperature control can be through the gas, liquid ratio to regulate, water washing and mixing temperature should not be lower than 95 ℃, the specific control ratio should be based on the actual working conditions to be determined after the calculation;

Step 3: the water washing tank in the high-temperature liquid pumped into the flash tank for flash evaporation, flash evaporation temperature can be controlled at 86-90 ℃, flash steam through the flash tank into the upper part of the vapour-liquid separation tank for vapour-liquid separation (vapour-liquid separation tank can be selected according to the actual flash, to determine whether or not to increase the vapour-liquid separation tank), flash out of the vapour into the twin screw air compressor for compression, pressurisation and temperature increase to achieve low-pressure steam requirements, the bottom of the tank to be calculated according to actual working conditions and then determined. Low-pressure steam requirements, the tank bottom of the high temperature liquid pumped to the evaporation crystalliser, into the evaporation crystallisation process section;

Step 4: the steam compressor will be pressurised and warmed after the low-pressure steam to the evaporation crystallizer for heat exchange, or direct external use can also be accessed in the production of low-pressure steam required in the process of low-pressure steam section;

Step 5: high-temperature waste liquid after evaporation and crystallisation, the secondary steam produced is reintroduced into the steam compressor or vapour-liquid separation tank, the secondary steam cycle is pressurised and reused to achieve its own heat cycle. Evaporation mother liquor can be applied or evaporated dry, or directly pumped to the sewage station for uniform treatment.

Step 6: The waste salt produced after evaporation and crystallisation can be treated as hazardous waste or solid waste, or treated according to whether there are high-value components in its components. If it has the economy of recyclability, then the next step of salt crystallisation, to achieve the goal of resource recovery and reuse.

Adopting the above process route:

- First of all, the low-temperature section of the furnace steam, flue gas in the latent heat is all taken out and used; secondly, the production of a certain temperature of the wastewater,

- Secondary use, which reduces the sewage station subsequent sewage treatment volume of the problem;

- Thirdly, the production of a certain amount of low-pressure steam, can reduce the consumption of fresh steam, to achieve the dual role of energy saving and emission reduction;

- Fourthly, the flue gas, furnace steam in some components through the Fourthly, some components of the flue gas and furnace steam can be crystallised in a way that turns them from gas treatment into hazardous waste and solid waste treatment, which can reduce the treatment volume and treatment costs.

In the evaporation crystallisation, you can use the thermal method of salt process, can be part of the economic value of the components through the crystallisation of salt recycling and reuse, to the enterprise to increase the economic benefits, reduce the cost of expenditure, and play a multi-purpose.

In recent years, we use this new process flow technology programme, has been for a number of production units to achieve the low-temperature section of the flue gas, furnace steam waste heat coupled use, to achieve energy saving, emission reduction, consumption reduction, efficiency goals, but from the comprehensive, efficient, low carbon, green production applications, there is still a lot of work to be done, and in the future, we will continue to improve the core technology process packages and equipment, to our petrochemical industry, “dual-carbon”.

We will continue to improve our core technology packages and equipment, so as to contribute to the realisation of the goal of “double carbon” in our petrochemical industry.