High Pressure Air Compressor for Laser Cutting Machine

How Air Compressors Drive Job Laser Cutting?

Laser cutting is no stranger to everyone, after all, laser cutting in the laser processing industry applications accounted for more than 7% of the laser processing industry, laser cutting with precision manufacturing, flexible cutting, shaped processing, one-time molding, speed, efficiency and other advantages, to solve many conventional can not be solved problems, the laser can cut the majority of metal materials and non-metallic materials.

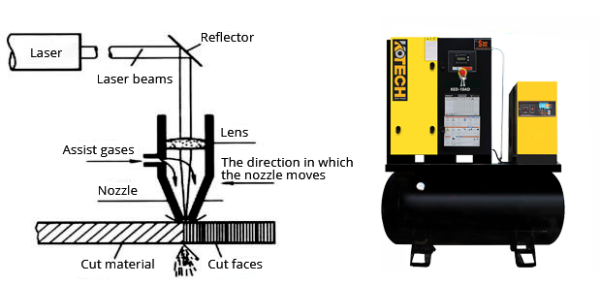

Laser cutting technology is under the action of the laser beam energy ( Laser cutting technology is under the action of the laser beam energy (oxygen-assisted cutting mechanism, but also with the addition of spray oxygen and reach the ignition point of the metal exothermic reaction of heat release), the material surface is rapidly (ms range) heated to thousands or even tens of thousands of degrees (℃) and melting or vapour, with the escape of the vapour and the molten object by the auxiliary high-pressure gas (oxygen or nitrogen and other inert gases) blowing away, the cut seam will be produced.

If you want to improve the processing efficiency of the laser cutting machine, add auxiliary gases, such as air, oxygen, nitrogen and other auxiliary gases when processing. The cost of compressed air is the lowest among all the auxiliary gases, so it has become the first choice of most customers.

In order to enhance the cutting effect, auxiliary equipment for laser cutting air compressor is a must have, how to choose a suitable air compressor for laser cutting machine?

Let’s take a look at the laser cutting air quality requirements:

Standards are as follows: dew point temperature ≤ -40 ℃, oil residue ≤ 0.003mg/m³, solid particles ≤ 0.01μm. To meet this requirement, the design of the compressed air purification system needs to ensure that the quality of compressed air in line with the international standard ISO8573-1 (GB/T13277-91) of the 1-2-1 level of quality requirements, if the air contains too much moisture, the harm is very great.

Is very big, not only will affect the operating efficiency of the air equipment, but also affect the cutting quality, serious burned laser head. This requires compressed air purification, including filtration and drying.

According to some data feedback common screw air compressor often have the following problems:

1. Small brand screw air compressor oil separation effect is poor, generally in the 3-10ppm, compressed air with high oil content.

2. The pressure is lower, the pressure drop is larger after using for a period of time.

3. The oil filter / oil material is general, oil filter / oil is not durable, easy to break through.

4. The oil used in the use of 46 ordinary mineral oil, easy to accumulate carbon.

5. Air quality has water, oil, laser head lens fog, a little attention will burn the laser head.

kotech air compressor manufacturer was founded in 2014, is engaged in air compressor system equipment and ancillary services professional suppliers, the current market 1.6MPa or more compressed air laser cutting machine is still the main use of piston air compressor and small brand screw air compressor, piston air compressor noise, wearing parts, and exhaust oil are not well handled, so the kotech screw air compressor special 16bar should be used.

(Integrated(2-In-1) Screw Air Compressor for Laser Cutting Machine)

Kotech laser cutting screw air compressor special 16bar came into being. Kotech also developed with the post-treatment equipment 16bar cooler and filter to ensure the service life of the laser cutting lens.

Kotech laser cutting screw air compressor has the following features:

■ First, the original host, the use of high-strength stainless steel piping, reduce the risk of oil leakage, oil drum thickened by 30%, security to improve the efficiency of 3 times.

■ Second, the whole machine dustproof design, filtering materials as thick as 10mm, more than 90% of the processing powder interception fully adapted to the harsh working environment.

■ Intelligent control, automatic start and stop, can also be controlled remotely, with high temperature protection, overcurrent protection, steering error protection, overpressure protection, the operation is also very simple.

■ Fourth, the original imported kotech high-efficiency filters, oil removal capacity, strong filter impurities, pressure reduction, long life.

■ Fifth, the gas storage tank to meet the increased demand for gas. Avoid the adverse effects of airflow fluctuations on the air point. At the same time, after cooling compressed air, discharge the moisture in the compressed air.

■ Sixth, the dryer to reduce the unloading time of the air compressor, reduce the load of the air compressor energy consumption, high efficiency water: water removal efficiency of 99.5% of the export of compressed air relative humidity as low as 10%. And more effective to achieve energy saving.

■ Seven, large factory products, European enterprises, with 149 years of manufacturing experience, more than 10 million users worldwide, easy maintenance, quality assurance.

Whether from the laser cutting quality considerations, or in order to ensure that the laser cutting head to consider the service life, kotech screw air compressor will be your optimal choice.

Jump to your selection➷

How does the air compressor work?

What does 2 Stage Air Compressor Mean?

How do Rotary Screw Air Compressors Work Diagram?

7.5 – 22 Kw Integrated Screw Air Compressor for Laser Cutting Machine

This type of compressor uses an integrated design with a 7.5 – 22 Kw engine to reduce energy consumption, resulting in a compressor that is quieter and more efficient.