5 Common Issues with Scroll Type Compressors and How to Fix Them

Introduction

Scroll type compressors play a crucial role in various industries, including food and beverage production, as well as air conditioning and refrigeration systems. Their unique design consists of one stationary spiral or scroll and one rotating spiral or scroll, which work together to compress air or refrigerant in a continuous and efficient manner. This design feature not only ensures high performance but also explains why they are widely used across different applications.

While scroll type compressors are widely used, they may experience a few common issues that can affect their performance and lifespan. It is important to identify signs such as leaks, loud noises, or excessive energy consumption early on to prevent further damage. In addition, problems like inadequate lubrication or failure of sealing components require prompt solutions to restore functionality.

This article serves as a complete guide to help you understand how scroll type compressors work. It covers the benefits and potential drawbacks of these machines while providing practical tips for troubleshooting and resolving problems. Whether you’re an experienced technician or new to compressor technology, you’ll find useful information to keep your scroll type compressor in optimal condition.

1. Understanding Scroll Type Compressors

Scroll type compressors are a type of positive displacement compressors that have greatly improved the way we create vacuum air and compression in various situations. They work by using two interlocking spiral-shaped scrolls—one stationary and one moving in a circular motion. As the moving scroll goes around, it traps and compresses air pockets between the scrolls, pushing them towards the center where the increased pressure allows for release into the system.

These compressors are simple yet ingenious devices that have transformed how we achieve vacuum air and compression in multiple settings. They operate on the principle of two interlocking spiral-shaped scrolls—one stationary and one moving in an orbital path. As the orbiting scroll moves, it traps and progressively compresses pockets of air between the scrolls, pushing them towards the center where the increased pressure allows for expulsion into the system.

The versatility of scroll compressors makes them essential in several industries:

- Industrial Machines: Scroll compressors power many automated processes by supplying reliable, clean compressed air that is crucial for precise operations.

- Food/Beverage Manufacturing: In these sectors, having compressed air that is free from contamination is extremely important; oil-free scroll compressors ensure that the air quality meets strict health standards.

- Air Conditioning: These compressors are popular for their quiet operation and efficiency, contributing to comfortable environments in homes and businesses.

- Refrigeration Systems: Scroll compressors handle refrigerant gases efficiently, playing a vital role in maintaining the cold chain for perishable goods.

With their continuous compression cycle, these small units provide a smooth flow of compressed air or refrigerant, making them indispensable tools that greatly improve operational efficiency across various applications.

2. Advantages and Disadvantages of Scroll Type Compressors

Scroll type compressors offer a variety of benefits that make them a popular choice in various industries.

Advantages of Scroll Type Compressors

- High Efficiency: Scroll compressors are known for their high efficiency. The unique design with two spiral-shaped scrolls compresses the air, resulting in minimal leakage due to the pressure difference between the inlet and outlet. This displacement compression offers the highest efficiency level by volume compared to other compressor types such as reciprocating compressors.

- Low Noise Operation: Another significant advantage is their low noise operation. Scroll compressors have fewer moving parts, leading to smooth, vibration-free operations. They have significantly lower noise emission levels than other types of compressors, making them ideal for environments sensitive to noise such as hospitals or offices.

Disadvantages of Scroll Type Compressors

- High Initial Costs: One downside is the higher initial costs associated with these compressors, primarily due to their oil-free mechanism and complex design. However, it’s worth noting that while the upfront investment may be higher than other compressor types, the long-term benefits often outweigh these costs.

- Repair Costs: Repairing a scroll compressor can be more expensive due to its hermetic sealing. Regular maintenance can help mitigate long-term repair expenses and ensure optimal performance.

Understanding these advantages and disadvantages can help you make an informed decision based on your specific needs and budget constraints.

3. Common Issues with Scroll Type Compressors: Causes and Solutions

Scroll compressors are known for their reliability, but like all mechanical devices, they can face specific issues that affect their performance. One such issue is the lack of lubrication.

working principle of oil-free scroll air compressor

3.1 Lack of Lubrication

Lack of lubrication is a significant issue when it comes to scroll compressors that can hinder their overall performance. Every moving part in a compressor needs proper lubrication to function smoothly. Without it, the components can wear out faster due to increased friction, leading to decreased efficiency and potentially costly repairs down the line.

Causes

The spiral-shaped scrolls in scroll compressors require proper lubrication to prevent them from wearing out prematurely due to excessive friction.

Effects

The impact of poor lubrication can be quite severe:

- Reduced Efficiency: The increased friction between moving parts can cause higher energy consumption, subsequently leading to reduced efficiency.

- Increased Wear and Tear: Excessive friction between the moving parts increases wear and tear, causing them to degrade at a faster rate.

- Overheating: Without sufficient lubrication, the scroll compressor may overheat due to increased friction between moving parts.

Solutions

To address this issue, regular maintenance is essential. Regularly checking the oil levels and refilling as necessary can ensure that your scroll compressor remains well-lubricated at all times.

However, if you are looking for a more convenient solution or operate in an industry that requires clean air quality (like food manufacturing or medical applications), oil-free scroll compressors could be an ideal choice. These compressors use materials with self-lubricating properties for their moving parts—eliminating the need for oil-based lubricants entirely. Not only does this maintain optimal performance without compromising air quality, but it also reduces the need for regular oil checks and refills.

3.2 Leakage Issues

Stay tuned for the next section where we will discuss another common problem with scroll compressors: leakage issues.

3.2 Leakage Problems

Next in line of scroll compressor issues is leakage, a common problem that can lead to reduced efficiency. The fact is, leakage problems are more likely to occur when the compressor isn’t maintained properly or undergoes heavy usage.

Here’s why: In a scroll compressor, two spiral-shaped scrolls compress air. One of the scrolls is fixed while the other orbits around it, gradually compressing air or gas towards the center of the housing. This unique design contributes to high internal compression efficiency with minimal leakage. However, when leaks do occur, they can significantly reduce this efficiency.

To combat this issue:

- Regular inspection is key. Check for leaks in all parts of your scroll compressor regularly – from the sealing components to the hose connections.

- Sealing any discovered leaks promptly will prevent further efficiency loss.

- Consider using digital scroll compressors which offer mechanical designs that match output to cooling requirements, ensuring precise temperature control and reduced likelihood of leaks.

Remember, understanding how your compressor works and its unique design features can help in effective troubleshooting and maintaining high performance levels.

3.3 Dealing with Excessive Noise in Scroll Compressors

Scroll compressors are known for their smooth and quiet operation, but there can be instances when they start making more noise than usual. This can be a sign of underlying issues that need to be addressed.

Why Excessive Noise is a Problem

Excessive noise from a scroll compressor can cause various problems:

- Impact on performance: The noise may indicate a decrease in efficiency or effectiveness of the compressor, resulting in poor cooling or air compression.

- Workplace disturbances: Loud noises can disrupt the working environment, leading to reduced productivity and increased stress levels among employees.

- Potential health risks: Prolonged exposure to high noise levels can have adverse effects on health, including hearing damage and stress-related illnesses.

Potential Causes of Excessive Noise

There are several reasons why a scroll compressor might start generating excessive noise:

- Faulty bearings

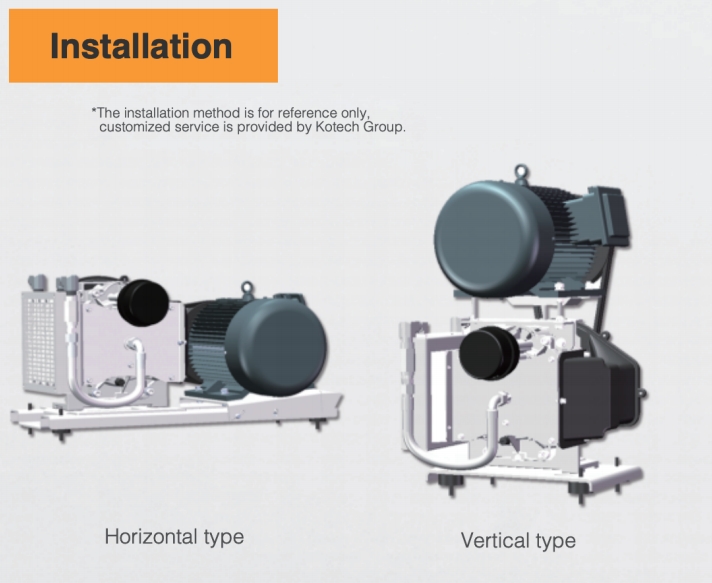

- Improper installation

- Wear and tear of internal components

If left unaddressed, these issues can escalate and result in more significant problems like complete mechanical failure.

Troubleshooting and Preventive Measures

Here are some steps you can take to identify and resolve the excessive noise issue with your scroll compressor:

- Identify the source: Try to pinpoint where exactly the noise is coming from. Is it the motor, the compressor itself, or any surrounding parts?

- Inspect for visible damage: Check if there are any obvious signs of damage or misalignment in the compressor or its components.

- Fix or replace faulty parts: If you find that worn-out bearings or other internal components are causing the noise, consider replacing them with new ones.

- Ensure proper installation: If the problem is related to installation, make sure that the compressor is correctly mounted and all fittings are secure.

- Reduce vibration: Excessive vibration can contribute to noise generation. Use anti-vibration pads or mounts to minimize this.

(The installation method is for reference onlycustomized service is provided by Kotech Group)

Tips to Reduce Noise Emission

While troubleshooting and fixing the underlying causes of excessive noise is essential, here are some additional measures you can take to minimize noise emission from your scroll compressor:

- Opt for models known for their low noise levels.

- Install sound insulation materials around your compressor.

- Regularly monitor and maintain your compressor to prevent wear and tear of parts.

By following these steps and best practices, you can not only address the current noise issue but also ensure a quieter working environment and optimal performance from your scroll compressor.

3.4 High Energy Consumption

High energy consumption is a significant issue with scroll compressors. It can increase operational costs and reduce efficiency. To address this problem, here are some key factors to consider:

Role of Variable Flow Technology

Incorporating variable flow technology into the mechanical design of scroll compressors can substantially lower energy usage. This technology adjusts the compressor output to match the demand, minimizing waste and promoting energy conservation.

Efficient Mechanical Design

Scroll compressors have a simplified, efficient design with fewer moving parts compared to other compressor types. This inherent design efficiency contributes to lower energy consumption when compared to less advanced models.

Regular Maintenance

Ensuring regular maintenance is performed on your scroll compressor is vital. Well-maintained components operate more efficiently and are less likely to consume excess energy.

Optimizing your scroll compressor’s energy consumption not only supports sustainable operations but also leads to cost savings over time. It’s important to leverage advancements in technology and consistent maintenance practices to combat high energy use.

3.5 Sealing Component Problems

Sealing component issues are a common challenge in scroll compressors. They can affect the compressor’s performance, leading to inefficiencies and potential system breakdowns.

Scroll compressors utilize seals to ensure that compressed air or gas doesn’t escape from the system. These seals, however, can suffer from wear and tear over time. When this happens, it results in leakage which ultimately impacts the efficiency of the entire system.

Types of Sealing Components

Two types of materials are often used for these sealing components: engineering plastics and metal seals. While both are effective in their own right, they offer different advantages.

- Engineering plastics are known for their corrosion resistance, light weight, and excellent sealing properties.

- On the other hand, metal seals have high strength and durability, making them ideal for heavy-duty applications.

Choosing the Right Seal

Choosing between these materials depends on your specific needs and application requirements. However, regardless of the type of seal you use, regular inspection and replacement are crucial. Worn-out seals can cause significant issues in scroll compressors if not addressed promptly.

Regular maintenance can help you detect these problems early on and take necessary actions to prevent major issues down the line.

4. Preventive Maintenance for Scroll Type Compressors

Regular maintenance and monitoring are pivotal in maintaining the long-term reliability of scroll type compressors. These practices not only ensure consistent performance but also extend the lifespan of the equipment. Here’s how you can implement a robust maintenance strategy:

Schedule Regular Inspections

Periodic checks can identify potential issues early, such as wear and tear on seals or bearings, before they lead to larger problems.

Clean Intake Vents and Filters

Keeping these components clean prevents dust and debris from entering the compressor, which could otherwise compromise its efficiency and air quality.

Monitor Temperature and Vibration

Unusual increases in these parameters could indicate an internal problem requiring immediate attention.

The Role of Advanced Air Compressor Control Systems

Advanced air compressor control systems play a critical role in green production and carbon reduction initiatives. Systems like Optimizer 4.0 are at the forefront of compressor technology, offering intelligent operation that can optimize performance while reducing energy costs.

The benefits of implementing such a system include:

- Real-Time Monitoring: Enables the tracking of system performance, allowing for adjustments to improve efficiency.

- Energy Savings: By optimizing compressor operation, these systems contribute to lower energy consumption and operational costs.

- Predictive Maintenance: With advanced analytics, you can predict when maintenance will be required, avoiding unexpected downtime.

Implementing these measures ensures that your scroll type compressors operate at peak efficiency, contributing to sustainable production practices and a reduced carbon footprint.

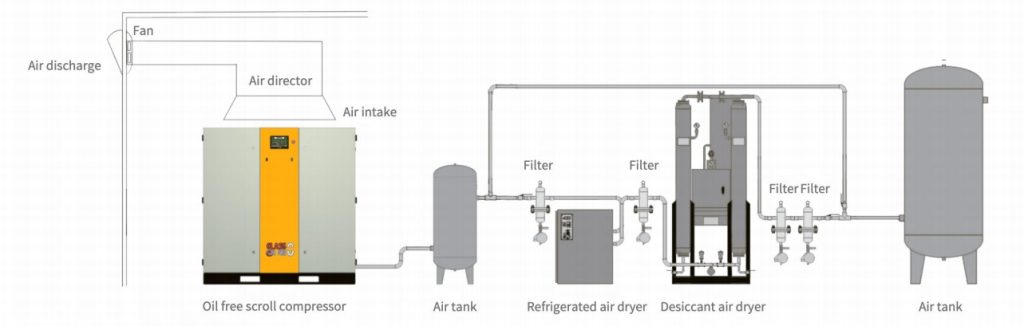

Oil free scroll air compressor system

Choosing the Right Scroll Type Compressor for Your Needs

Selecting the right scroll type compressor is crucial to ensure optimal performance, longevity, and cost-effectiveness. Here are some key factors to consider when making your decision:

1. Reliability

Scroll compressors are known for their reliability due to their simple design with fewer parts compared to other types of compressors. When choosing a compressor, think about how reliable it needs to be and how much maintenance it will require.

2. Energy Efficiency

Because of their unique design, scroll compressors have high efficiency at certain airflows compared to other compressors. When comparing compressors, look at their energy ratings and consider features like variable speed control that can help reduce energy use.

3. Brand Reputation

The reputation of the brand or manufacturer can often give you an idea of the quality of the compressor. Some brands, like Atlas Copco, are known for making reliable, efficient, and cost-effective scroll compressors.

4. Application Requirements

Think about what you need the compressor for and how much air it will need to make. For example, if you need oil-free air, an oil-free scroll compressor might be a better choice than one that uses oil.

A well-chosen scroll compressor can make a big difference in how well your system works and how much it costs to run. It’s important to think about both the upfront cost of the compressor and how much it will cost to operate and maintain over time.

Conclusion

Scroll type compressors are essential in various industries such as food and beverage manufacturing, air conditioning, refrigeration, and industrial machinery. To ensure their best performance and lifespan, it’s important to address common problems like:

- Lack of lubrication

- Leakage issues

- Excessive noise

- High energy consumption

- Sealing component problems

The troubleshooting guide provided in this article gives useful information on what causes these problems and how to solve them. However, some issues might need professional help that goes beyond what this guide covers. If you face such problems, don’t hesitate to reach out to a skilled technician who specializes in scroll type compressors.

Remember, it’s always better to prevent problems than to deal with them later on. Regular maintenance and servicing can help you avoid many common issues, saving both time and money in the long term. When buying a new compressor, consider getting high-quality products from trusted suppliers like Kotech Compressor. This not only reduces the chances of facing common problems but also gives you superior performance and durability.

Ready to find the perfect scroll type compressor for your needs? Check out Kotech Compressor’s range of scroll type compressors. With their great prices and wide selection, making the right choice has never been easier. Get yourself a reliable scroll type compressor that matches what you need exactly and enjoy smooth operations for years to come.